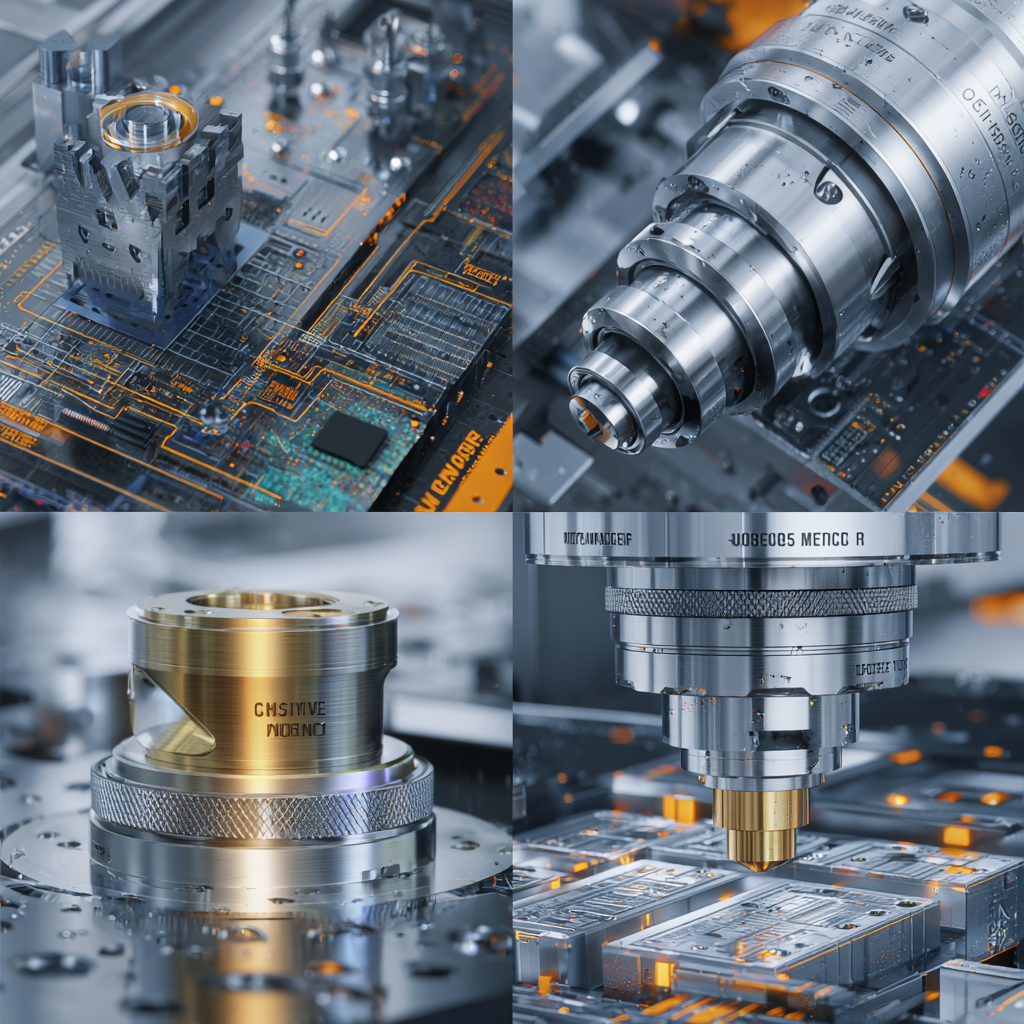

2025 Top Machining Tools: Revolutionizing Precision and Efficiency in Manufacturing

The landscape of manufacturing is undergoing a significant transformation, primarily driven by advancements in machining tools. In 2025, the industry is expected to witness a paradigm shift, emphasizing precision, efficiency, and adaptability in machining operations. According to a report by Grand View Research, the global machining tools market is projected to reach USD 170 billion by 2025, reflecting a compound annual growth rate (CAGR) of 6.2%. This growth is fueled by increasing automation and the integration of smart technologies, which are crucial for maintaining competitiveness in an ever-evolving market.

Dr. Alex Thompson, a leading expert in machining technologies, emphasizes the importance of these tools in enhancing productivity: “The future of manufacturing lies in our ability to leverage advanced machining tools that not only optimize production but also ensure accuracy at unprecedented levels.”

As manufacturers embrace innovations such as computer numerical control (CNC) systems, high-speed machining, and advanced materials, the role of machining tools becomes increasingly central to operational success. The push towards sustainability and energy efficiency further underscores the need for modern machining solutions that cater to these growing demands.

In this evolving context, understanding the top machining tools of 2025 is pivotal for industry stakeholders. By exploring the latest trends and technologies, manufacturers can better navigate the challenges ahead and seize opportunities to improve their production capabilities. The convergence of precision and efficiency in machining tools is not just a trend; it is a critical element of the future of manufacturing.

The Rise of Smart Machining Tools in 2025

The rise of smart machining tools in 2025 signifies a transformative shift in the manufacturing landscape, driven by rapid advancements in technology. These innovative tools leverage artificial intelligence, machine learning, and the Internet of Things (IoT) to enhance precision and efficiency. By integrating real-time data analysis and automated processes, manufacturers can achieve unprecedented accuracy in machining operations, reducing waste and minimizing downtime.

In an era where speed and precision are paramount, smart machining tools offer the capability to adapt to changing production demands instantly. This versatility not only streamlines workflows but also enhances productivity across various sectors. Moreover, the implementation of augmented reality and predictive maintenance features enables operators to foresee potential issues and address them proactively, thus ensuring optimal equipment performance. As the manufacturing industry embraces these cutting-edge technologies, the future looks promising for enhanced operational capabilities and sustainability.

2025 Top Machining Tools: Revolutionizing Precision and Efficiency in Manufacturing

Innovative Materials for Enhanced Machining Performance

In the ever-evolving landscape of manufacturing, the introduction of innovative materials has significantly enhanced machining performance. Advanced composites, ceramics, and superalloys are leading the charge, redefining the boundaries of what is achievable in precision machining. These materials not only exhibit exceptional durability and resistance to wear under extreme conditions but also allow for more intricate designs, ultimately improving production efficiency.

Furthermore, the integration of lightweight materials is transforming machining processes. By reducing the overall weight of components without sacrificing strength, manufacturers can optimize their operations and enhance the speed of production. This shift not only accelerates machining cycles but also minimizes energy consumption during manufacturing, contributing to a more sustainable production environment. As manufacturers adopt these innovative materials, they are poised to achieve unprecedented levels of precision and efficiency, setting new standards for the industry.

Automation and AI Integration in Precision Manufacturing

The integration of automation and artificial intelligence (AI) is reshaping precision manufacturing, heralding a new era of efficiency and productivity. As manufacturers adopt advanced robotics and AI technologies, they significantly enhance operational processes, enabling for repeatability and reduced costs. This transformation is especially evident in the electronic manufacturing services (EMS) sector, where automation plays a pivotal role in integrating sophisticated technologies that streamline production.

Tips for Successful Automation: Invest in staff training to maximize the benefits of new technologies. Ensure that employees are equipped with the necessary skills to work alongside AI and robotics, as this human-technology collaboration is crucial for achieving optimal efficiency. Additionally, focus on data analysis; leveraging analytics can provide insights that enhance decision-making and process improvements.

The automotive industry is also experiencing a substantial shift, with the demand for robotic solutions driven by electric mobility and precision engineering. As more companies explore smart manufacturing strategies, the integration of AI not only boosts productivity but also supports sustainable practices. Embracing this technological evolution positions manufacturers to meet the challenges of the future while maintaining competitiveness in a rapidly advancing market.

2025 Top Machining Tools: Revolutionizing Precision and Efficiency in Manufacturing - Automation and AI Integration in Precision Manufacturing

| Tool Type | Material Compatibility | Precision Level (μm) | Speed (RPM) | Automation Features | AI Integration |

|---|---|---|---|---|---|

| CNC Lathe | Aluminum, Steel, Titanium | 5 | 1500 | Automatic Tool Changes | Predictive Maintenance |

| CNC Milling Machine | Plastics, Nylon, Bronze | 10 | 2000 | In-process Measurement | Real-time Adjustment |

| Laser Cutter | Metal, Wood, Glass | 15 | 3000 | Computerized Beam Control | Pattern Recognition |

| 5-Axis Machining Center | Carbon Fiber, Aluminum Alloys | 2 | 1200 | Multi-tool Automation | Adaptive Learning |

| EDM Machine | Alloy, Carbide | 1 | 800 | Fully Automated Sequencing | AI Process Optimization |

Sustainability in Machining: Eco-Friendly Techniques and Tools

As the manufacturing sector continues to evolve, sustainability has become a critical focus, particularly in machining processes. The Global Manufacturing 2030 Report indicates that about 70% of manufacturers worldwide are actively seeking eco-friendly techniques to minimize their carbon footprint. This shift not only helps the environment but also enhances efficiency. Tools that utilize advanced materials, such as bio-based cutting fluids, can significantly reduce waste and energy consumption, leading to both cost savings and sustainable practices.

Implementing sustainable machining techniques can involve several strategies. For instance, utilizing energy-efficient machinery and optimizing cutting parameters can decrease energy use by up to 25%, according to the Manufacturing Energy Consumption Survey. Additionally, recycling metal shavings and chips can reduce raw material costs by up to 30%, fostering a circular economy in manufacturing.

**Tips:**

1. **Choose Eco-Friendly Materials:** Opt for tools made from sustainable materials that reduce environmental impact.

2. **Invest in Energy-Efficient Equipment:** Evaluate machinery for energy ratings to lower energy consumption and costs.

3. **Implement Waste Reduction Strategies:** Establish a recycling program for metal scraps to maximize resource efficiency.

Cost-Efficiency: Balancing Quality and Budget in Manufacturing

In the competitive landscape of modern manufacturing, achieving cost-efficiency is paramount. Manufacturers are increasingly tasked with balancing quality and budget while optimizing their resources. The latest advancements in machining tools offer solutions that not only enhance precision but also streamline production processes, ultimately reducing operational costs. By integrating state-of-the-art technology, companies can maintain high standards of craftsmanship without compromising their financial health.

One effective strategy involves investing in multi-functional tools that reduce the need for multiple machines, thereby saving on both initial capital and maintenance expenses. Additionally, the adoption of smart technology in machining tools can lead to more accurate forecasting, minimizing waste and excess production. By leveraging data analytics, manufacturers can identify inefficiencies in their processes and make informed decisions that impact their budget positively. Such innovations empower businesses to deliver quality products while keeping an eye on profitability, proving that excellence in manufacturing need not come at a steep price.

Related Posts

-

Exploring the Future of Plastic Parts: Innovations Shaping Tomorrow's Manufacturing

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations

-

What is Micro Machining? A Comprehensive Guide to Its Techniques and Applications

-

How to Achieve Superior Results with Super Finishing Techniques

-

Understanding the Plastic Injection Moulding Process: A Comprehensive Guide for Beginners