How to Achieve Super Finishing for Enhanced Surface Quality in Manufacturing

In the competitive landscape of modern manufacturing, achieving superior surface quality is paramount. One of the most effective techniques for enhancing surface finish is "super finishing," a process recognized for its ability to reduce surface roughness to microscopic levels. Recent studies indicate that components with superior surface finishes can lead to a reduction in friction by up to 30%, significantly improving the performance and longevity of mechanical parts. According to a report by the International Journal of Advanced Manufacturing Technology, the implementation of super finishing techniques in various industries can increase productivity by 15% while simultaneously cutting down on material waste.

Moreover, the demand for high-precision components has surged, particularly in sectors such as aerospace, automotive, and medical devices, where safety and reliability are non-negotiable. A survey conducted by the Manufacturing Institute reveals that 70% of companies prioritize surface finish when selecting suppliers, underscoring the importance of mastering super finishing processes. As technology evolves, embracing advanced finishing techniques will not only help manufacturers meet strict quality standards but also optimize their production processes. Thus, understanding and implementing super finishing methods is crucial for manufacturers striving for excellence and competitiveness in today's rigorous market environment.

Understanding Super Finishing in Manufacturing Processes

Super finishing is a critical process in manufacturing that significantly enhances the surface quality of components. This advanced finishing technique is designed to refine surface roughness beyond what is achievable with traditional machining methods. By utilizing specialized tools and techniques, super finishing reduces surface imperfections and improves the overall smoothness of a material, resulting in enhanced performance characteristics such as reduced friction, increased resistance to wear, and improved fatigue strength.

The understanding of super finishing processes involves grasping various techniques including abrasive, non-abrasive, and chemical finishing methods. Abrasive techniques, such as micro-abrasive blasting or ultra-fine grinding, focus on the precise removal of surface irregularities to achieve desired dimensional tolerances. Non-abrasive methods, like magnetic float polishing or vibratory finishing, employ different principles to achieve a smooth surface without significant material removal. Additionally, chemical techniques, including electropolishing, utilize chemical reactions to remove surface layers, enhancing the aesthetics and functionality of the product. By mastering these processes, manufacturers can ensure that components meet stringent quality standards essential for high-performance applications.

Principles of Super Finishing Techniques for Surface Quality

Super finishing techniques are essential in enhancing the surface quality of manufactured components. These methods, which include processes such as honing, lapping, and superabrasive grinding, are designed to achieve the lowest possible surface roughness while maintaining dimensional accuracy. The principles behind super finishing focus on refining the surface texture through controlled interactions between the workpiece and finishing tools. By utilizing fine abrasives and slower feed rates, manufacturers can produce ultra-smooth surfaces that significantly reduce friction and wear.

In addition to achieving a glossy finish, super finishing plays a crucial role in improving the functional performance of parts. This process not only enhances the aesthetic quality but also influences various mechanical properties such as fatigue strength and corrosion resistance. The careful selection of abrasives and the precise control of finishing parameters are pivotal in maximizing the benefits of these techniques. As manufacturers strive to meet increasingly stringent quality standards, understanding the underlying principles of super finishing becomes indispensable for delivering high-performance components in competitive industries.

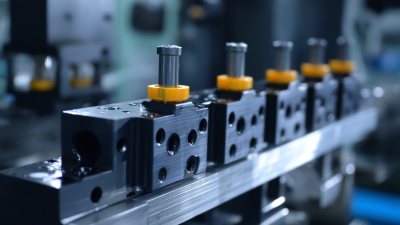

Tools and Equipment Used for Super Finishing

Achieving super finishing in manufacturing processes significantly improves the surface quality of components, leading to enhanced performance and longevity. Essential tools and equipment play a critical role in this refinement process. Abrasive-based finishing tools, such as honing stones and super abrasives like cubic boron nitride (CBN) and diamond, are frequently employed. According to a recent industry report, tools comprised of super abrasives can increase the material removal rate by up to 40% compared to traditional abrasives, celebrating the efficiency brought forth by technological advancements in tool manufacturing.

In addition to abrasive tools, specialized machines such as super finishing machines and vibratory finishing equipment are fundamental to achieving the desired surface finish. These machines are designed to operate at micro-level precision, allowing for the removal of 1 to 10 micrometers of material without compromising the integrity of the workpiece. The Global Super Finishing Equipment Market Report indicates a projected growth of 7.8% annually, reflecting the rising demand for precision-engineered components across various sectors, including aerospace and automotive. The integration of advanced sensing technologies into these machines further enhances their capabilities, enabling real-time monitoring and adjustments to ensure optimal surface quality.

Applications of Super Finishing in Various Industries

Super finishing is a critical process utilized across various industries to enhance surface quality, providing significant improvements in the performance and longevity of components. In the automotive sector, super finishing techniques are employed to refine engine parts, transmission components, and gears. By reducing surface roughness, this process minimizes friction and wear, leading to improved fuel efficiency and overall vehicle performance. Additionally, it enhances the durability of components under stress, ensuring reliability and longevity in high-performance applications.

In the aerospace industry, the importance of super finishing cannot be overstated. Components such as turbine blades and structural elements benefit from a meticulously smooth surface that reduces drag and improves aerodynamics. This results in increased fuel efficiency and reduced emissions, which are critical for modern aviation standards. Furthermore, in medical device manufacturing, super finishing enhances the biocompatibility of implants and surgical instruments, ensuring that surfaces are not only smoother but also safer for human interaction. Overall, the application of super finishing across these industries demonstrates its vital role in achieving high-performance standards and fostering innovation in manufacturing processes.

How to Achieve Super Finishing for Enhanced Surface Quality in Manufacturing - Applications of Super Finishing in Various Industries

| Industry | Application | Benefits | Common Techniques |

|---|---|---|---|

| Automotive | Engine Components | Reduced friction, increased durability | Diamond and Superfinishing Stones |

| Aerospace | Turbine Blades | Improved efficiency and lifespan | Microfinishing and Honing |

| Medical Devices | Surgical Instruments | Enhanced biocompatibility, better precision | Electropolishing and Abrasive Flow Machining |

| Electronics | Component Housings | Improved thermal performance and aesthetic quality | Ultrasonic Machining and Lapping |

| Oil & Gas | Pumps & Valves | Higher resistance to wear and corrosion | Centerless Grinding and Fine Finishing |

Evaluating the Effectiveness of Super Finishing Methods

Super finishing is a critical process in manufacturing aimed at enhancing the surface quality of components. This method is particularly effective in achieving nano-scale surface finishes, which significantly improve the performance and longevity of parts used in various industries, such as automotive and aerospace. By using techniques like abrasive flow machining, super finishing can reduce surface roughness and enhance geometrical precision. Evaluating the effectiveness of these methods involves measuring key parameters such as surface roughness, form accuracy, and the material removal rate.

Through systematic experimentation, manufacturers can analyze how different super finishing techniques impact the surface quality of different materials. Advanced measuring tools, such as profilometers, allow for accurate assessment of surface finish, providing valuable feedback on process improvements. Comparing the results from various super finishing methods helps in identifying the most efficient techniques for specific applications, ultimately leading to improved product performance and reduced manufacturing costs. The ongoing evaluation is vital for optimizing processes and ensuring that manufacturers meet the ever-increasing quality standards in today's competitive market.

Related Posts

-

Why Super Finishing Is Essential for Achieving a Surface Roughness of Up to Ra 0.1µm

-

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

-

Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes

-

Top Benefits of Super Finishing Process for Precision Engineering Applications

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

2025 Top Machining Tools: Revolutionizing Precision and Efficiency in Manufacturing