Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

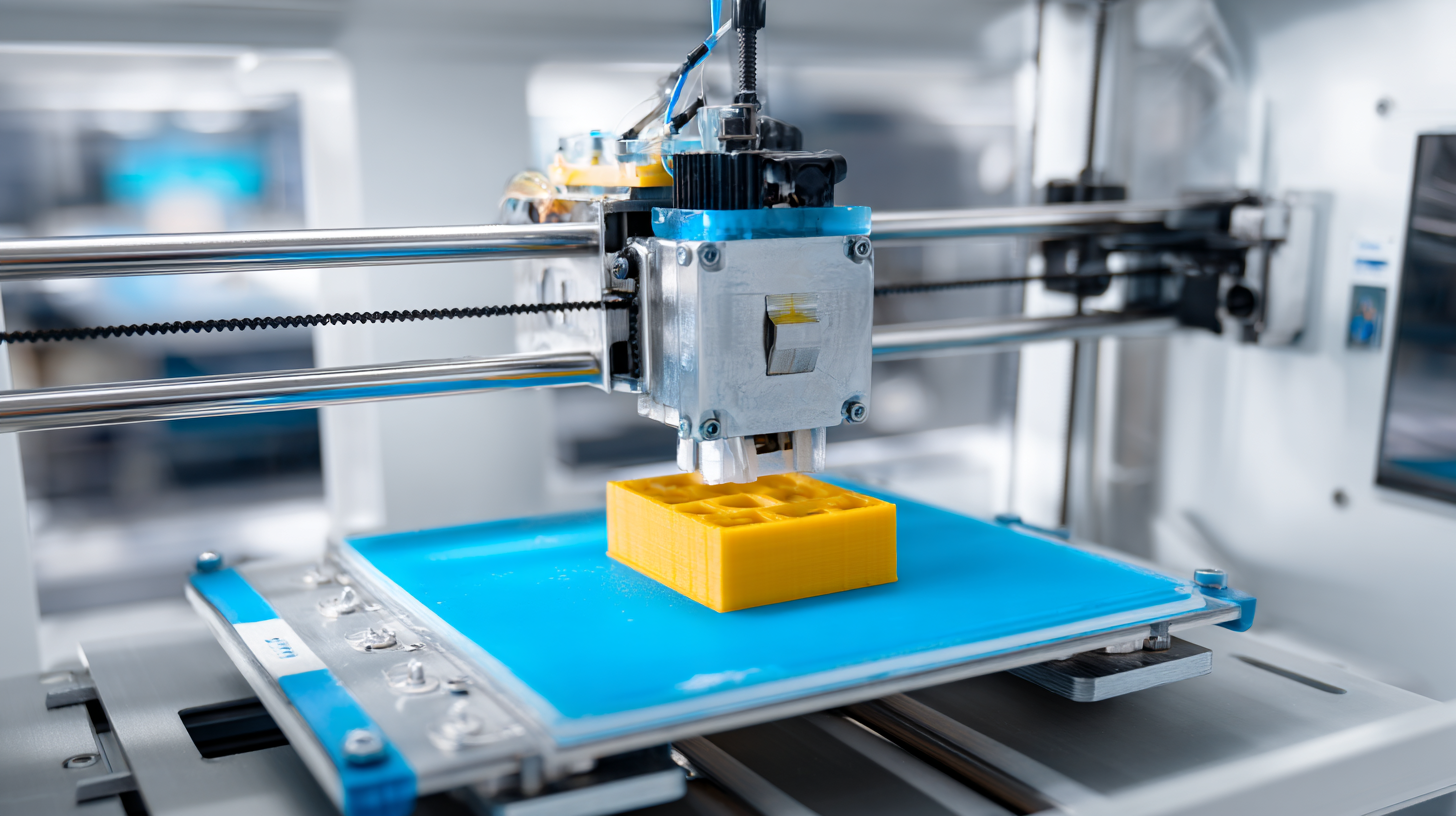

As the world gears up for the 138th Canton Fair in 2025, anticipation surrounds the latest advancements in additive manufacturing. This innovative approach, often referred to as 3D printing, is revolutionizing the manufacturing landscape, offering unprecedented flexibility and efficiency in production processes. The Canton Fair provides a unique platform for industry leaders, researchers, and innovators to showcase their latest creations and discuss cutting-edge technologies that are shaping the future of manufacturing. With the integration of additive manufacturing techniques, businesses can explore new design possibilities, reduce waste, and enhance customization, thereby staying competitive in an increasingly globalized market. Attendees can expect to encounter a diverse array of exhibits that highlight the potential of additive manufacturing across various sectors, from aerospace to healthcare, making this year's event a crucial milestone in the evolution of manufacturing technology.

Innovative 3D Printing Technologies Showcased at the 2025 Canton Fair

The 2025 Canton Fair in China is set to be a pivotal moment for additive manufacturing, showcasing the latest innovations in 3D printing technologies. Recent industry reports, including the Wohlers Report 2023, project that the global 3D printing market will reach approximately $45 billion by 2025, driven by increasing applications across various sectors such as aerospace, healthcare, and automotive. These advancements will be prominently featured at the Fair, demonstrating how additive manufacturing is transforming traditional production methods.

Notable highlights will include advances in materials science, with companies unveiling new filament types that enhance durability and reduce production costs. One such innovation is the development of bio-based materials, which can significantly reduce the environmental impact of 3D printing. Additionally, breakthroughs in multi-material printing are expected to allow manufacturers to create complex, tailored components in a single process, which can lead to significant time and resource savings. As industry leaders gather at the Canton Fair, the integration of these technologies will illustrate the growing importance of additive manufacturing in achieving sustainable and efficient production practices.

Additive Manufacturing Innovations at the 2025 Canton Fair

Key Industry Leaders and Startups Driving Additive Manufacturing Forward

At the 2025 Canton Fair in China, the spotlight is on key industry leaders and innovative startups that are shaping the future of additive manufacturing (AM). Recent industry reports, such as the 2023 Annual Review of Additive Manufacturing, indicate that the global market for AM is projected to reach a staggering $55 billion by 2026, growing at a compound annual growth rate (CAGR) of over 25%. This exponential growth is driven by advancements in materials and technology, which allow for greater customization, reduced waste, and accelerated production times.

Prominent companies, including XYZPrinting and Formlabs, are showcasing their latest breakthroughs in 3D printing technologies. Startups like Carbon and Markforged are also making waves with their unique approaches to polymer and metal additive manufacturing, pushing the boundaries of what is possible. According to a report by SmarTech Analysis, the adoption of AM in industries such as aerospace and healthcare is surging, with these sectors expected to account for more than 50% of market demand by 2025. As the Canton Fair opens its doors, attendees are eager to explore these innovations and their implications for the future of production and design.

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China - Key Industry Leaders and Startups Driving Additive Manufacturing Forward

| Company Type | Innovation Focus | Technologies Used | Market Segment | Geographical Reach |

|---|---|---|---|---|

| Established Players | Metal 3D Printing | Laser Powder Bed Fusion | Aerospace and Automotive | Global |

| Startups | Bioprinting | Extrusion Technology | Healthcare | Asia-Pacific |

| Established Players | Polymer 3D Printing | Fused Deposition Modeling | Consumer Products | North America |

| Startups | Construction 3D Printing | Concrete Printing | Construction | Europe |

| Research Institutions | Advanced Materials Development | SLA and SLS | Industrial Applications | Worldwide |

Comparative Analysis of Traditional Manufacturing vs. Additive Manufacturing

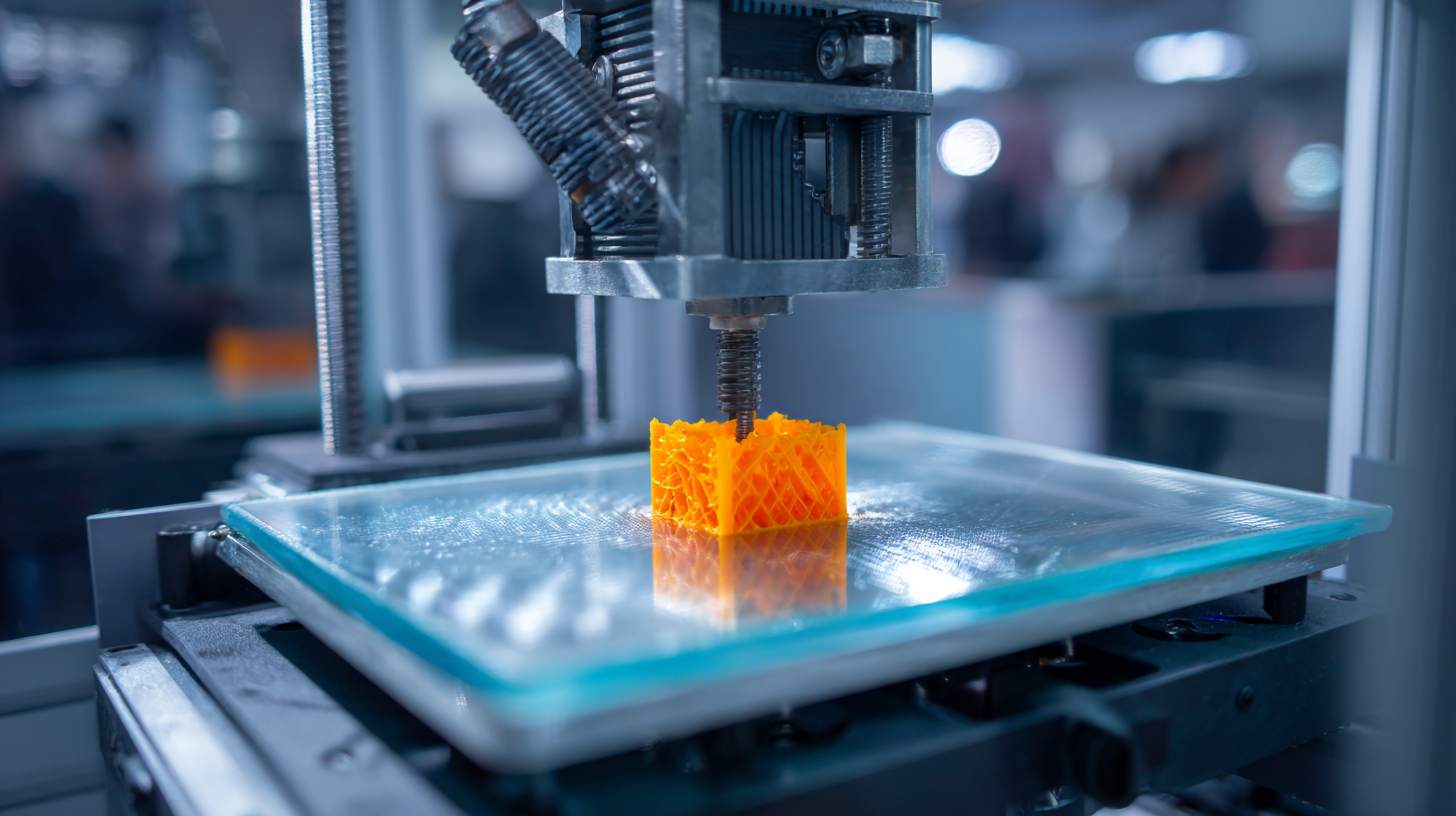

Additive manufacturing (AM) has gained significant traction as a viable alternative to traditional manufacturing methods, especially with recent innovations in material sciences. For instance, the integration of titanium in 3D printing processes is poised to revolutionize this field, as titanium alloys possess unique properties like high strength-to-weight ratios and excellent corrosion resistance. A recent market analysis highlights that the global titanium 3D printing market is expected to reach a valuation exceeding $2 billion by 2025, indicating a crucial turning point for large-scale adoption.

In contrast, traditional manufacturing methods require extensive tooling and longer lead times, limiting design flexibility. A study suggests that while traditional metal fabrication processes can lead to increased material waste—up to 30%—additive manufacturing optimizes material use and minimizes waste generation, with certain processes achieving efficiencies as high as 90%. Additionally, studies reveal that businesses integrating AM solutions into their supply chains report a 50% reduction in development time and costs, affirming the transformative potential of additive manufacturing in enhancing production efficacy across various industries.

Future Trends in Additive Manufacturing: Insights from the Canton Fair

The 2025 Canton Fair presents an unparalleled platform for showcasing the latest innovations in additive manufacturing (AM). As industries increasingly pivot towards digital fabrication technologies, insights gained from this influential event highlight future trends that are set to redefine production and design. According to a recent report by Smithers Pira, the global additive manufacturing market is projected to reach $29.3 billion by 2026, demonstrating a compound annual growth rate (CAGR) of over 22%. This robust growth is driven by advancements in 3D printing materials and techniques, which enhance production speed and reduce costs.

In particular, the fair will spotlight developments in polymer and metal 3D printing, reflected in a projected increase in metal AM adoption by 25% annually, as noted by Wohlers Associates. Innovations such as multi-material printing and sustainable practices, including bio-based and recycled materials, are anticipated to dominate discussions. Engaging industry leaders at the Canton Fair will provide crucial insights into the integration of AI and machine learning in AM processes, further enabling customization and efficiency in manufacturing. These trends not only promise to elevate the production capabilities across various sectors but also signal a transformative shift towards more sustainable and flexible manufacturing solutions.

Networking Opportunities and Collaborations in the Additive Manufacturing Sector

The 2025 Canton Fair in China will serve as a pivotal platform for

networking and collaboration within the additive manufacturing sector.

As the industry continues to grow, the global additive manufacturing market is expected to reach

USD 41 billion by 2026, according to a report by MarketsandMarkets.

This growth opens up vast opportunities for professionals and companies to connect, share knowledge,

and foster partnerships that can drive innovation forward.

Networking opportunities at the fair will include

interactive workshops, panel discussions, and matchmaking events designed to link industry leaders

with emerging businesses. A study by Wohlers Associates indicates that the additive manufacturing industry

has seen an annual growth rate of 25.7% over the past several years.

This momentum emphasizes the importance of collaboration as companies seek to leverage

new technologies and enhance operational efficiencies.

Engaging with peers at the Canton Fair can facilitate the exchange of best practices and catalyze

collective advancements in 3D printing technologies, materials, and applications.