Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

In the realm of modern manufacturing, the process of creating plastic injection molded parts stands out as a pivotal technology that drives efficiency and precision. According to a report by Markets and Markets, the global plastic injection molding market size is projected to reach USD 400.12 billion by 2025, growing at a CAGR of 5.2%. This growth is attributed to the increasing demand for lightweight materials across various industries, including automotive, consumer goods, and electronics. By utilizing advanced machinery and computer-aided design, manufacturers can produce intricate plastic components with high dimensional accuracy and repeatability. Furthermore, plastic injection molded parts offer significant advantages over traditional manufacturing methods, such as reduced waste, lower production costs, and the ability to fabricate complex geometries that are increasingly important in today’s fast-paced market. Understanding this process not only highlights the importance of plastic injection molding but also paves the way for leveraging its benefits in achieving competitive advantages in product development.

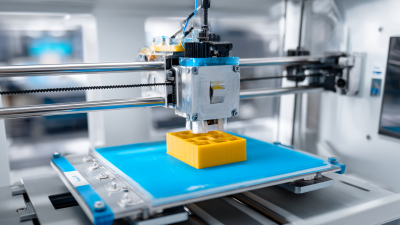

The Basics of Plastic Injection Molding: An Overview of the Process

Plastic injection molding is a widely utilized manufacturing process that transforms plastic materials into precisely shaped parts and components. The procedure begins with the melting of plastic granules, which are then injected into a mold under high pressure. This allows for the production of complex shapes with high accuracy and repeatability. Once the plastic cools and solidifies, the mold is opened to eject the finished part, ready for further processing or assembly.

Tips: When considering plastic injection molding for your projects, it's essential to select the right type of plastic material based on your application requirements. Different plastics offer varying levels of durability, flexibility, and heat resistance. Additionally, investing in high-quality molds can significantly reduce production errors and improve overall efficiency.

Another key aspect is the control of the cooling time during the injection molding process. Proper cooling is crucial to achieving dimensional accuracy and surface quality. Shortening the cooling time can enhance production speed, but be cautious, as it may affect the structural integrity of the molded parts. Regular maintenance of your machinery and molds can also help in minimizing downtime and ensuring consistent quality in production.

Understanding the Advantages of Plastic Injection Molding

Key Advantages of Using Injection Molded Parts in Modern Production

Injection molded parts have rapidly become essential in modern manufacturing due to their intricate design capabilities, cost-effectiveness, and efficiency. One of the key advantages of using injection molded components is the ability to produce high volumes of consistent quality parts with minimal waste, making it an environmentally friendly choice. Recent advancements in manufacturing technologies, particularly in the realm of lightweight composite structures, enable the integration of innovative materials, such as carbon fiber reinforced thermoplastics, into the injection molding process. This not only enhances the mechanical properties of the final products but also expands application possibilities across various industries.

Moreover, the implementation of intelligent data-driven systems for mold manufacturing has revolutionized production customization. By incorporating knowledge graphs and reinforcement learning, manufacturers can optimize mold designs for specific part requirements, minimizing lead times and enhancing adaptability. The potential to recycle polymer plastics and integrate sustainable practices into injection molding further underscores the versatility of this approach, positioning it at the forefront of modern production techniques. The growing market for plastic injection molding highlights the ongoing evolution and importance of this technology in fulfilling the demands of diverse applications.

Factors Influencing the Quality of Injection Molded Components

The quality of injection molded components is influenced by several critical factors that must be carefully managed throughout the manufacturing process. One of the primary factors is the choice of material. Different plastics have varying properties that can significantly affect the durability, finish, and overall performance of the molded parts. Understanding the specific requirements of the final product helps manufacturers select the most suitable resin, which can minimize defects and ensure consistency.

Another important factor is the design of the mold itself. A well-engineered mold can facilitate better material flow and reduce the likelihood of air traps, which are common issues in injection molding. Additionally, mold temperature and pressure settings play pivotal roles in determining the quality of the final product. These parameters must be optimized to achieve the desired characteristics, such as surface finish and dimensional accuracy. Regular maintenance of the injection molding equipment also contributes to maintaining high standards in component quality, ensuring longevity and reliability in production runs.

Innovations in Injection Molding Technology for Enhanced Efficiency

Injection molding technology has seen significant advancements in recent years, driving innovation in the manufacturing sector. One notable development is the use of advanced materials and additives that improve the characteristics of molded parts, allowing for customized solutions that meet specific industry requirements. According to a 2022 study by Grand View Research, the global injection molding market was valued at approximately $238.5 billion and is expected to expand at a CAGR of 3.8% from 2023 to 2030, reflecting the growing demand for efficiency and precision in production.

Additionally, the integration of smart technology and automation in the injection molding process has further enhanced efficiency. By incorporating IoT devices and real-time monitoring systems, manufacturers can optimize material flow, reduce cycle times, and minimize waste. A report from MarketsandMarkets indicates that the smart manufacturing market is projected to reach $516.0 billion by 2026, with injection molding being a crucial sector benefiting from this trend. These innovations not only streamline operations but also contribute to sustainability efforts, as manufacturers can produce high-quality parts using less energy and raw materials, paving the way for a more environmentally friendly manufacturing landscape.

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

| Dimension | Description | Benefits | Applications |

|---|---|---|---|

| Material Variety | Different types of plastics can be used for injection molding. | Greater flexibility in product design and functionality. | Consumer goods, automotive components, medical devices. |

| Cycle Time | Time taken to complete one cycle of the injection process. | Faster production rates lead to increased output. | Mass production in various industries. |

| Precision | High levels of accuracy in molded parts. | Minimizes waste and reduces the need for assembly. | Electronics, appliances, and complex designs. |

| Cost Efficiency | Lower costs per part at scale. | Cost-effective for large production runs. | Industry-wide applications from toys to tools. |

| Sustainability | Use of recycled plastics and low-energy processes. | Reduced environmental impact of production. | Eco-friendly products and packaging solutions. |

Best Practices for Sourcing and Designing Injection Molded Parts

When sourcing and designing injection molded parts, understanding the best practices is crucial to optimizing the manufacturing process and ensuring product quality. Industry reports, such as the "2022 Modern Manufacturing Report," highlight that companies utilizing advanced sourcing strategies see up to a 20% reduction in production costs. Effective sourcing begins with identifying reliable suppliers who have a proven track record in producing high-quality molds and parts, leveraging technologies such as computer-aided design (CAD) to streamline the design process.

Moreover, the design phase is vital in enhancing manufacturability and reducing lead times. A study published by the American Society of Mechanical Engineers notes that designs optimized for injection molding can reduce cycle times by 30%, significantly improving overall efficiency. Adopting practices such as design for manufacturability (DFM) and involving the manufacturing team early in the design process allows companies to mitigate potential issues that may arise during production. By prioritizing these best practices, manufacturers can not only improve the quality of their injection molded parts but also gain a competitive edge in the increasingly demanding market.

Related Posts

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025