Top 10 Benefits of Additive Manufacturing Technology in Modern Industry

Additive manufacturing technology, often referred to as 3D printing, has revolutionized the way industries design and produce goods. Unlike traditional subtractive manufacturing processes, which involve cutting away material to create objects, additive manufacturing builds components layer by layer from the ground up. This transformative approach offers numerous advantages, making it an increasingly popular choice among businesses across various sectors.

The impact of additive manufacturing technology goes beyond mere efficiency; it fosters innovation, reduces waste, and allows for unprecedented customization in product development. By leveraging this technology, manufacturers can streamline operations, minimize costs, and enhance product performance. In this article, we will explore the top ten benefits of additive manufacturing technology in modern industry, highlighting how this groundbreaking method is reshaping the landscape of production and paving the way for a more sustainable and adaptable future.

Benefits of Additive Manufacturing Technology in Reducing Production Costs

Additive manufacturing technology, often referred to as 3D printing, is revolutionizing production processes by significantly reducing costs. One of the primary ways it achieves this is through the minimization of material waste. Traditional manufacturing often involves subtractive processes, where excess materials are cut away, leading to a substantial loss. In contrast, additive manufacturing builds objects layer by layer, using only the necessary amount of material needed for the final product. This efficiency not only lowers raw material costs but also reduces the expenses associated with waste disposal.

Another economic advantage is the reduction in lead times. With additive manufacturing, the time required for prototyping and production is drastically shortened. Companies can rapidly design and produce parts without the lengthy setup times associated with traditional manufacturing methods. This agility allows businesses to respond quickly to market demands and reduces holding costs for inventory.

**Tips:** To maximize savings with additive manufacturing, consider smaller batch production runs that can capitalize on the technology's flexibility. Also, invest in training for staff to fully leverage design software and ensure optimal print settings, further enhancing efficiency and reducing costs. Embracing this technology can unlock new opportunities for innovation while driving down operational expenses.

Enhancing Design Flexibility through Additive Manufacturing Techniques

Additive manufacturing, often referred to as 3D printing, has revolutionized the way industries approach design and production. One of the most significant advantages of this technology is its enhanced design flexibility. Traditional manufacturing methods often impose constraints that limit creativity and innovation. However, additive manufacturing allows for the creation of complex geometries and intricate designs that were previously deemed impossible. This opens up a whole new realm of possibilities for engineers and designers, enabling them to push the boundaries of what their products can achieve.

Tips for maximizing design flexibility with additive manufacturing include focusing on the unique capabilities of the technology. For instance, take advantage of the ability to create lightweight structures through lattice designs. This not only reduces material costs but also enhances the functionality of the final product, making it more efficient and easier to handle. Additionally, consider utilizing parametric design software that allows for rapid iterations and modifications, streamlining the process from concept to prototype.

Moreover, integrating additive manufacturing into the design process can significantly shorten the product development cycle. By creating prototypes directly from digital designs, teams can test and refine their concepts in real-time, fostering a culture of innovation. Encouraging collaboration between design and manufacturing teams can further enhance the benefits of additive technology, leading to products that are not only functional but also aesthetically pleasing. Embracing this technology is essential for companies aiming to stay competitive in today’s fast-paced market.

Top 10 Benefits of Additive Manufacturing Technology in Modern Industry

The chart below illustrates the top benefits of additive manufacturing technology, highlighting its impact on modern industry, particularly regarding design flexibility.

Improving Supply Chain Efficiency with Additive Manufacturing Solutions

Additive manufacturing (AM) technology, commonly known as 3D printing, has emerged as a transformative force in modern industry, particularly in enhancing supply chain efficiency. By allowing for the rapid production of complex components on-demand, AM reduces the need for extensive inventory. Companies can manufacture parts when they are needed, thus minimizing warehousing costs and reducing the risk of overproduction. This just-in-time approach not only streamlines inventory management but also enables companies to respond more swiftly to changing market demands and customer preferences.

Additionally, additive manufacturing fosters more localized production, which can significantly diminish supply chain vulnerabilities. Traditional manufacturing often relies on global suppliers and long shipping timelines, which can be disrupted by geopolitical tensions or logistics challenges. With AM, businesses can establish production facilities closer to their end-users, reducing lead times and transportation costs. This decentralized model helps organizations to adapt more readily to shifts in demand while maintaining a more resilient supply chain, ultimately leading to greater operational flexibility and sustainability.

Increasing Customization Opportunities in Modern Manufacturing Industries

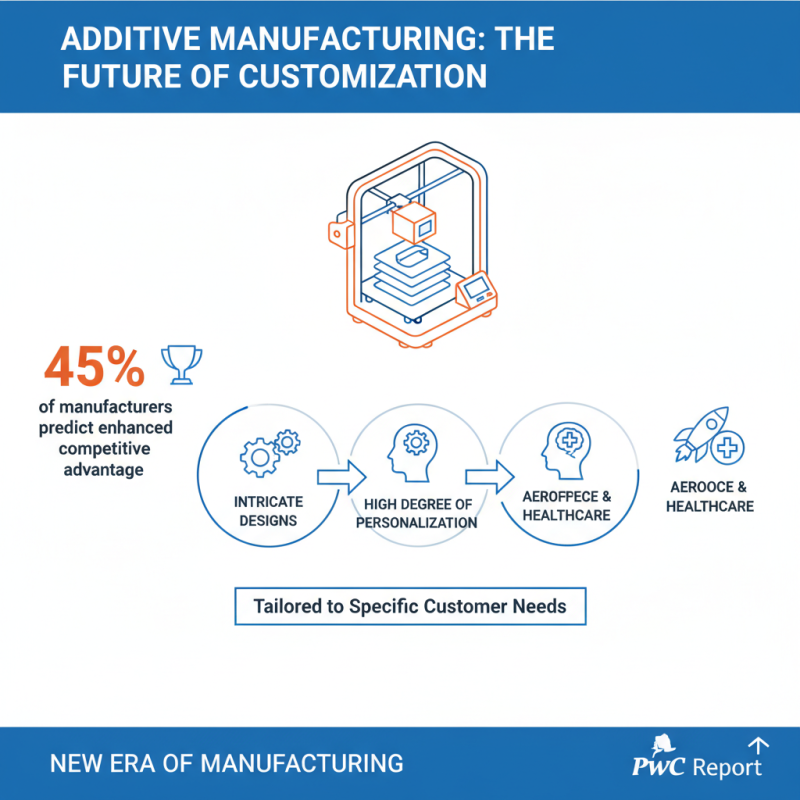

Additive manufacturing technology has ushered in a new era of customization in modern manufacturing industries. This innovative approach allows companies to create intricate designs that were previously unattainable through traditional manufacturing methods, thus enabling a high degree of personalization for consumers. According to a report by PwC, 45% of manufacturers believe that additive manufacturing will enhance their competitive advantage by enabling the production of customized products tailored to specific customer needs. This capability is particularly significant in sectors such as aerospace and healthcare, where bespoke components can lead to improved performance and better patient outcomes.

The growing demand for customized products is driving a transformation in manufacturing processes. A study by Deloitte indicates that nearly 1 in 3 consumers are willing to pay more for personalized products, highlighting the monetary benefits of adopting additive manufacturing technology. This technology not only reduces lead times but also minimizes material waste, making it an appealing choice for businesses looking to balance sustainability with customer satisfaction. Furthermore, the ability to rapidly prototype and iterate designs accelerates innovation and allows manufacturers to respond quickly to market trends, emphasizing the continuous improvement cycle that customization fosters in modern industries.

Driving Sustainability Initiatives with Additive Manufacturing Practices

Additive manufacturing technology, often recognized for its innovative production capabilities, plays a pivotal role in advancing sustainability initiatives across various industries. By utilizing a layer-by-layer approach, this technology minimizes waste by only using the necessary material to create products. Traditional manufacturing methods often result in significant excess material, which contributes to environmental degradation. In contrast, additive manufacturing allows for more precise designs that not only reduce material waste but also enable the use of recycled materials, further supporting sustainability efforts.

Moreover, the flexibility inherent in additive manufacturing supports the transition to more sustainable supply chains. By enabling localized production, companies can decrease transportation emissions associated with shipping goods over long distances. This proximity to consumers not only reduces the carbon footprint but also enhances responsiveness to market demands, allowing for more efficient inventory management. As industries increasingly focus on sustainable practices, additive manufacturing stands out as a transformative technology that aligns production methods with environmental stewardship, fostering a more sustainable future for manufacturing as a whole.

Top 10 Benefits of Additive Manufacturing Technology in Modern Industry

| Benefit | Description | Impact on Sustainability |

|---|---|---|

| Material Efficiency | Additive manufacturing uses only the necessary materials, reducing waste compared to traditional methods. | Significantly lowers material waste, promoting responsible consumption. |

| Customization | Allows for tailored products that meet specific user needs without excess inventory. | Reduces overproduction and supports circular economy principles. |

| Reduced Energy Consumption | Lower energy requirements during production processes compared to traditional manufacturing. | Contributes to lower carbon footprint per product manufactured. |

| Rapid Prototyping | Accelerates the product development cycle, reducing time to market. | Allows for faster iterations, minimizing resource use in unsuccessful designs. |

| On-Demand Production | Products can be produced as needed rather than creating large inventories. | Decreases storage needs and associated energy consumption. |

| Design Complexity | Enables intricate designs that are lighter and stronger. | Leads to less material use while enhancing product performance. |

| Supply Chain Simplification | Reduces the need for complex supply chains by localizing production. | Minimizes transportation emissions and logistical waste. |

| Innovation Acceleration | Encourages new ideas and rapid testing of advanced concepts. | Supports sustainable innovations that can transform industries. |

| Resource Recovery | Eases the recycling of materials back into the production cycle. | Fosters a closed-loop system, enhancing sustainability efforts. |

| Long-term Cost Savings | Initial investment may be higher, but reduces costs in production and waste management. | Incorporates economic sustainability by reducing overall costs in the long run. |

Related Posts

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

Why Super Finishing Is Essential for Achieving a Surface Roughness of Up to Ra 0.1µm

-

2025 How to Choose the Right Injection Tooling for Your Manufacturing Needs

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Exploring the Future of Plastic Parts: Innovations Shaping Tomorrow's Manufacturing