Top Benefits of Injection Molded Parts for Efficient Manufacturing Solutions?

Injection molded parts play a crucial role in modern manufacturing. They allow for the efficient production of complex shapes with high precision. According to a report by MarketsandMarkets, the global injection molding market is projected to reach $378.2 billion by 2025, driven by rising demand across various industries.

These parts offer numerous benefits, including reduced material waste and lower labor costs. The process enables manufacturers to create high volumes of identical products swiftly. However, achieving optimal efficiency requires careful planning and quality control. Not every manufacturer fully understands the intricacies of injection molding.

Moreover, while injection molded parts are cost-effective, initial setup costs can be significant. Each mold needs to be made with precision, impacting lead times. Recognizing these challenges is essential for companies to maximize the advantages of injection molded parts. A balanced approach ensures manufacturers can enhance productivity while addressing potential pitfalls.

Key Advantages of Injection Molding in Manufacturing Processes

Injection molding offers significant advantages in manufacturing processes. This method allows for high precision and consistency in producing parts. The ability to create complex geometries is essential for many applications. Injection molding can reduce material waste, which makes it an environmentally friendly option.

Here are a few tips to maximize the benefits of injection molding. First, focus on the design phase. Poorly designed parts may lead to defects. Always consider the ease of manufacturing when creating designs. Also, select appropriate materials based on functional requirements. Not all plastics are suitable for every application.

Another consideration is cycle time. While injection molding can be fast, optimizing processes is key. Even small adjustments can greatly enhance efficiency. Monitor the equipment regularly to avoid downtimes. Delays in production can lead to increased costs. Manufacturers should continuously evaluate their processes to improve quality and reduce errors. This reflection can lead to better outcomes over time.

Top Benefits of Injection Molded Parts for Efficient Manufacturing Solutions

| Benefit | Description | Impact on Manufacturing |

|---|---|---|

| Cost Efficiency | Reduced production costs due to rapid production cycles and material efficiency. | Lower costs allow for more competitive pricing in the market. |

| Precision and Accuracy | High dimensional accuracy with tight tolerances achieved through injection molding. | Enhanced product quality and consistency. |

| Design Flexibility | Ability to create complex shapes and designs that are difficult to achieve with other manufacturing methods. | Supports innovative product development and customization. |

| Material Variety | A wide range of materials can be used, including thermoplastics and elastomers. | Allows manufacturers to choose the best material for the product's requirements. |

| Low Labor Costs | Automation and streamlined processes reduce the need for manual labor. | Increased profitability and reduced operational costs. |

| Sustainability | Efficient material use and the ability to recycle materials contribute to eco-friendly practices. | Alignment with global sustainability initiatives and consumer demand. |

Cost Efficiency and Reduced Waste in Injection Molded Parts

Injection molding is a popular manufacturing process that offers significant cost efficiency. By creating parts in large quantities, businesses can reduce their per-unit costs considerably. The setup costs can be high initially, but with mass production, the savings can accumulate rapidly. This efficiency becomes even more notable when considering how material costs are minimized through precise molding techniques.

Reduced waste is another major benefit of injection molded parts. The process allows for nearly all of the material used to be formed into the final product, minimizing scrap and excess. This is particularly advantageous in industries where material costs are rising. However, it's essential to consider that not every design meets these efficiency benchmarks. Some designs may require excessive adjustments or lead to overengineering, which can negate the benefits.

Moreover, the need for high-quality molds means manufacturers must invest in quality control. Occasionally, the need for adjustments introduces some level of waste anyway. Striking the right balance between design, production efficiency, and cost is vital. It often requires a cycle of trial, error, and reassessment to truly capitalize on these benefits.

Design Flexibility and Precision in Injection Molding Techniques

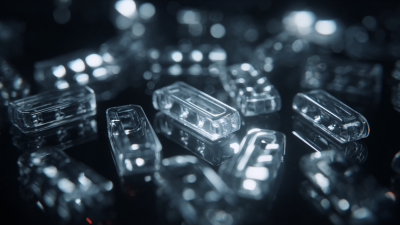

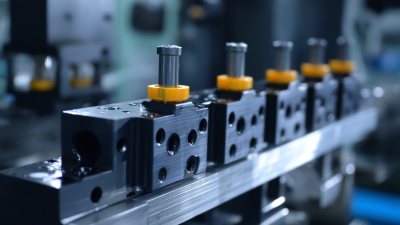

Injection molding is a game-changer in manufacturing. It allows for remarkable design flexibility. Engineers can create complex geometries that were once difficult or impossible to achieve. This flexibility can lead to innovative solutions. Different materials can be used, expanding functional capabilities.

Precision is another key aspect of injection molding. With the right techniques, tolerances can be maintained within microns. This accuracy is crucial for parts that require a perfect fit. Every detail counts in high-performance applications. However, achieving this level of precision requires careful planning. A slight miscalculation in design can lead to costly errors.

While injection molding offers many benefits, it can pose challenges. Not every design translates well into molded parts. Some features may not fill properly during production. Engineers must remain vigilant and committed to refining designs. Continuous improvement and learning from defects are necessary. Balancing creativity and manufacturability is essential for successful outcomes.

Speed and Scalability: Enhancing Production Rates with Injection Molding

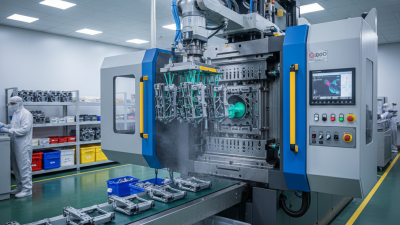

Injection molding is revolutionizing manufacturing. It offers remarkable speed and scalability. According to a recent industry report, injection molding can produce thousands of parts in a single day. This rate dramatically outpaces traditional manufacturing methods.

The process starts with molten plastic being injected into molds. Cooling and solidification occur quickly, allowing for rapid part production. A recent study highlighted that companies can reduce production costs by up to 30% using injection molding. This method also minimizes waste, as excess material can often be recycled.

However, challenges exist. Mold design is complex and can lead to higher initial costs. Additionally, achieving perfect quality in every batch is not guaranteed. Some manufacturers report inconsistencies, necessitating extra inspections. These issues highlight the need for continuous improvement in processes. Emphasizing speed and scalability, injection molding remains a powerful solution for efficient manufacturing.

Top Benefits of Injection Molded Parts for Efficient Manufacturing Solutions

This bar chart illustrates the top benefits of injection molded parts for efficient manufacturing solutions, rated on a scale of 1 to 10. As evidenced by the data, production speed is the most significant benefit, contributing to enhanced manufacturing efficiency.

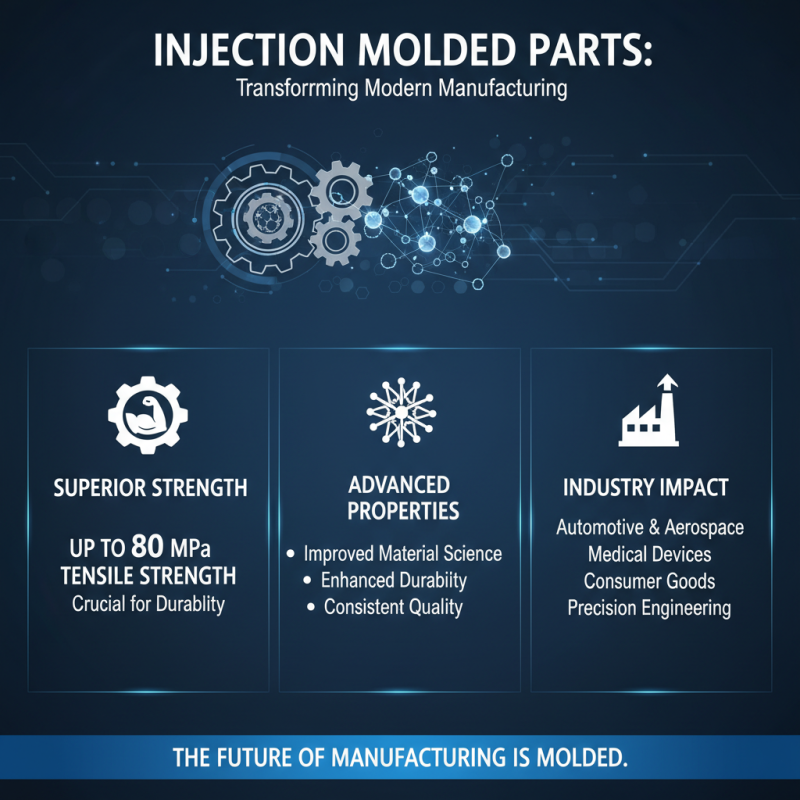

Improved Material Properties and Strength of Injection Molded Components

Injection molded parts are transforming modern manufacturing. The improved material properties and strength of these components set them apart from traditional methods. According to recent studies, injection molding can yield products with a tensile strength as high as 80 MPa. This is crucial for industries that demand durability.

Injection molding employs various thermoplastics and composites. This enables manufacturers to select materials that fit their specific needs. For instance, polycarbonate can withstand high impact, making it a top choice for safety equipment. Unexpected issues may arise, such as the risk of warping or uneven cooling. Awareness of these pitfalls is essential.

The efficiency of production is also noteworthy. The cycle time for injection molding is often less than 30 seconds for a single part. This rapid output can lead to significant time savings. However, mold design and initial setup can be expensive. Companies must carefully assess their requirements before diving into large-scale production. Balancing cost and quality remains a challenge in achieving optimal results.

Related Posts

-

Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing

-

What is Injection Molded Parts and How They are Made

-

2025 How to Choose the Right Injection Tooling for Your Manufacturing Needs

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations

-

Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes

-

The Best 10 Plastic Mold Techniques You Should Know?