2026 Best Industrial Applications for Innovative Technology Solutions?

In the evolving landscape of technology, industrial applications play a crucial role in driving efficiency. Experts like Dr. Emily Carter, a leading figure in industrial innovation, have noted, “Innovative technology solutions are reshaping how industries operate.” This statement encapsulates the current trend where businesses leverage technology to improve processes and reduce costs.

Industries are increasingly adopting automation, artificial intelligence, and IoT solutions. These technologies provide real-time data, enhance decision-making, and streamline production. However, the integration of such innovations often presents challenges. Many organizations struggle with implementation. Failing to fully understand technological capabilities can lead to wasted resources.

As we explore the best industrial applications in 2026, it’s vital to recognize both successes and shortcomings. Some companies achieve remarkable gains, while others realize that technology alone is not a cure-all. Balancing innovation and practical application is essential for sustainable growth. The journey toward effective industrial applications requires reflection and adaptability.

Emerging Technologies Revolutionizing Industrial Applications in 2026

In 2026, various innovative technologies are reshaping industrial applications. Automation and artificial intelligence are at the forefront. Factories are increasingly using smart robotics to enhance productivity. These robots can perform complex tasks with precision.

Tips: Invest in training your workforce alongside adopting new technologies. A knowledgeable team can maximize the benefits of smart solutions. Continuous learning is key.

Another technology making waves is the Internet of Things (IoT). Sensors on machines collect real-time data. This data helps in predictive maintenance, reducing downtime. However, integration can be challenging. Not all systems communicate effectively. Reflection on existing processes is essential.

Tips: Start small with IoT investments. Test on a single machine or process. Gradually scale to avoid overwhelming your operations. An agile approach can yield better results. Embrace the changes, but adapt slowly.

Key Sectors Leveraging Innovative Technology Solutions in Industry

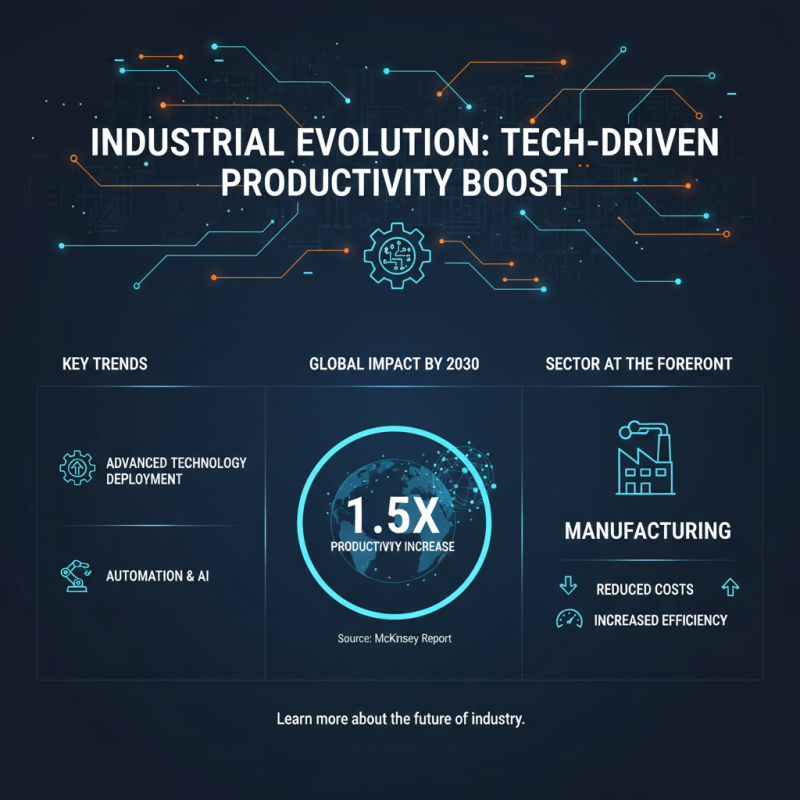

The industrial landscape is evolving rapidly. Key sectors are increasingly deploying innovative technology solutions. According to a report by McKinsey, advanced technologies could boost productivity by 1.5 times globally by 2030. Manufacturing stands at the forefront of this transformation. Automation and AI are reducing costs while increasing output efficiency.

In the energy sector, companies are embracing digital solutions to optimize operations. The International Energy Agency reports that digitalization could save up to $200 billion by 2040. However, many firms struggle with integration. Legacy systems often hinder progress. Cybersecurity remains a critical concern, with potential vulnerabilities that need addressing.

Healthcare is another vital area. Telemedicine has surged, driven by the pandemic. Yet, a KPMG report indicates that data privacy challenges remain significant. Providers must adapt while maintaining patient trust. Innovation in technology can enhance outcomes, but it also brings risks. Balancing these factors is essential for the future of industrial applications.

Top Innovative Technology Solutions Transforming Manufacturing Processes

In 2026, innovative technology solutions are redefining manufacturing processes. Automation is becoming increasingly critical. Robots handle tasks that once required human speed and precision. This shift reduces errors and increases productivity. However, it is essential to monitor these systems closely. Over-reliance on automation can lead to a lack of skilled workers.

Here’s a tip: invest in training programs. Equip your staff with the skills they need to work alongside advanced technologies. This approach fosters a culture of innovation and adaptability. Combining human intelligence with machine efficiency can create unparalleled results.

Another crucial solution is data analytics. Real-time data improves decision-making and production quality. Manufacturers can analyze patterns and predict failures before they occur. However, data privacy remains a concern. Effective management of this data is paramount to avoid potential breaches.

Tip: always prioritize cybersecurity. Protecting sensitive data should never be an afterthought. Enhancing data security not only builds trust but also strengthens your operational foundation.

Impact of AI and Automation on Industrial Efficiency and Productivity

The industrial landscape is evolving rapidly. AI and automation play crucial roles in this transformation. Companies are increasingly adopting these technologies to enhance efficiency and productivity. For instance, automation in manufacturing reduces human errors. This leads to higher quality products and faster output. Workers often feel uncertain about these changes. Job displacement becomes a real concern, sparking debates about the future of work.

AI optimizes supply chains and reduces costs. Machine learning algorithms analyze data to forecast demand accurately. However, reliance on technology raises questions about resilience. What happens when systems fail? Companies need strategies for these scenarios. Additionally, not everyone benefits equally from automation. Smaller businesses may struggle to keep up. This creates disparities that require careful consideration.

Implementing innovative technologies has challenges. Employee training is critical to ensure smooth transitions. Fear of job loss can lead to resistance. Companies must foster a culture of support and adaptability. Embracing automation is not only about efficiency. It's also about creating a sustainable future with equitable opportunities for all. Balancing these factors will determine the success of industrial applications in the coming years.

Impact of AI and Automation on Industrial Efficiency and Productivity

Sustainable Innovation in Industrial Technology: Trends and Applications

As industries pivot towards sustainability, innovative technology solutions are becoming crucial. Recent research indicates that the global market for sustainable industrial technology will exceed $600 billion by 2026. This shift emphasizes reducing waste and enhancing efficiency. For instance, companies are now adopting hyper-automation and AI-driven analytics to streamline processes. This approach can cut operational costs by up to 30%.

Tips: Evaluate the current processes in your organization. Identify areas where automation could enhance sustainability and efficiency.

Real-world applications show promise. For example, smart manufacturing is on the rise. By integrating IoT sensors, industries monitor energy usage in real time. This can lead to a reduction of energy consumption by up to 25%. Many firms, however, struggle with data integration and security challenges, which complicate this transition.

Tips: Invest in training for staff to better understand data analytics. This knowledge can help in utilizing technology efficiently.

Sustainable innovation is not just about adopting new tools; it's also about mindset. As industries explore new technologies, continuous feedback loops are essential. This approach allows for iterations and improvements, which can be key to long-term success.

Related Posts

-

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

-

What Types of Manufacturing Applications Are Transforming Industry Today?

-

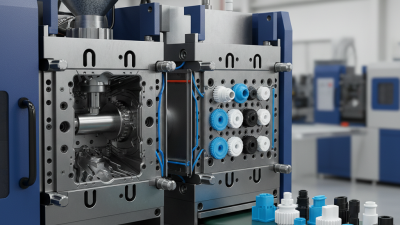

Top 10 Advantages of the Plastic Injection Moulding Process You Need to Know

-

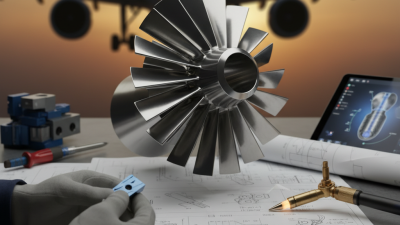

10 Essential Tips for Using Titanium Alloys in Your Projects?

-

2026 How to Choose the Right Injection Mold Tooling for Your Project?

-

Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing