How to Choose the Right Injection Mold Inserts for Your Manufacturing Needs

In the ever-evolving landscape of manufacturing, selecting the right injection mold inserts is crucial for achieving efficiency and product quality. Industry expert Dr. John Smith, a leading authority in polymer processing, emphasizes the importance of this decision: "Choosing the correct injection mold inserts can significantly reduce production time and enhance product durability." This statement highlights the critical role that these components play in the injection molding process, influencing both the economy and reliability of manufacturing operations.

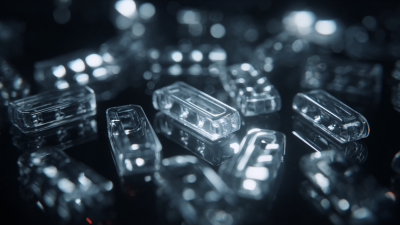

Injection mold inserts are integral to the creation of complex shapes and precision components, often determining the success of a production run. With a plethora of materials, designs, and functionalities available, manufacturers must navigate an intricate selection process. From thermoplastic to thermoset applications, understanding the characteristics and performance metrics of various mold inserts is essential to make informed choices that align with production goals.

The following guide will provide actionable tips and insights on selecting the right injection mold inserts, ensuring that manufacturers can optimize their processes while meeting stringent product standards. By examining key considerations such as material compatibility, mold design, and production volume, manufacturers can make strategic decisions that elevate their operational efficiency and product quality.

Key Factors to Consider When Selecting Injection Mold Inserts for Manufacturing

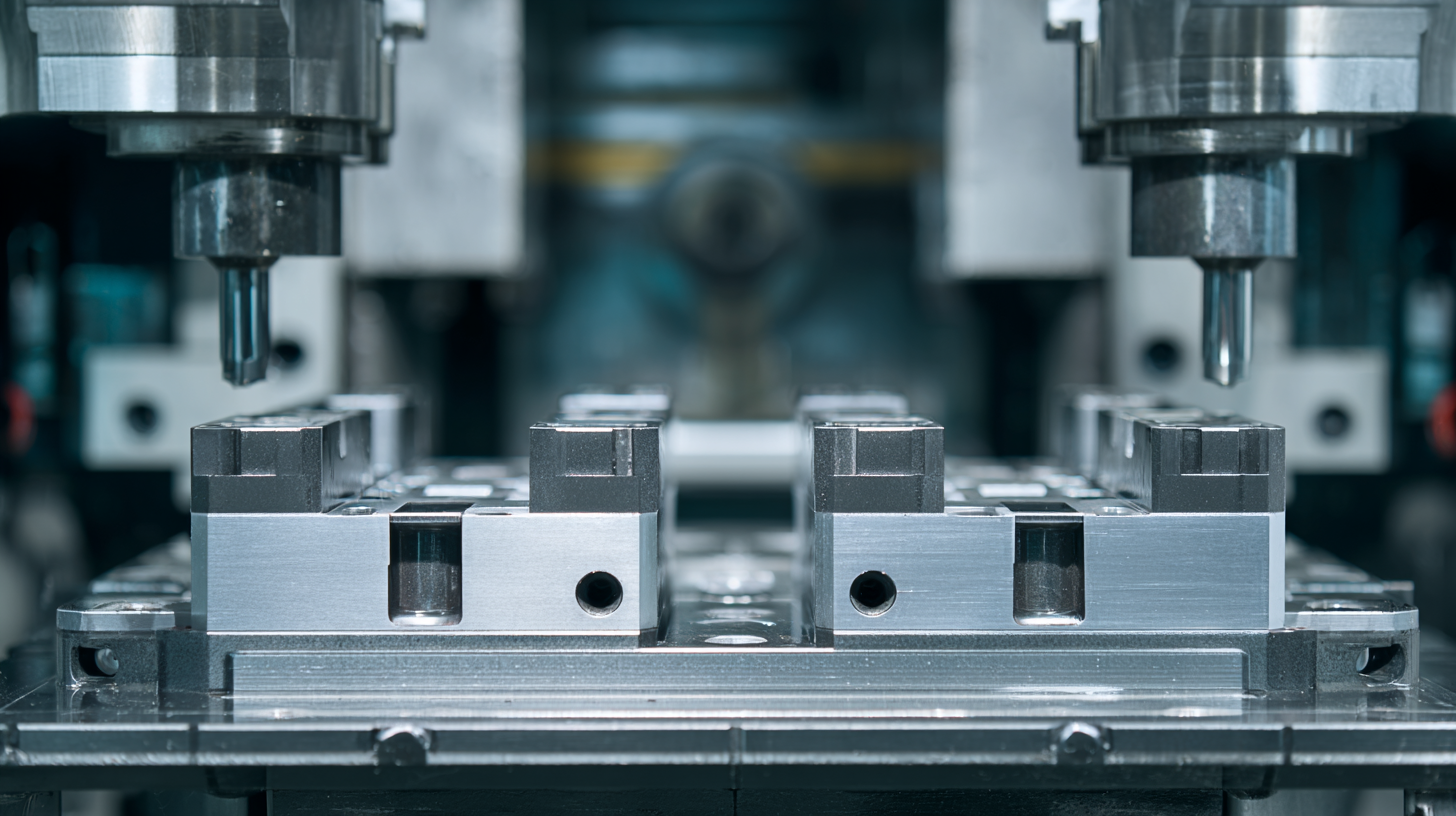

When selecting injection mold inserts for manufacturing, several key factors must be considered to ensure operational efficiency and product quality. First and foremost, the material of the mold insert plays a critical role. Common materials include steel and aluminum, each with distinct properties influencing durability and heat conductivity. For applications requiring high precision and durability, steel inserts are preferred due to their strength and longevity. In contrast, aluminum may be suitable for lower-volume runs due to its lightweight nature and easier machinability.

Another essential factor is the complexity of the part design. The intricacy of the product dictates the design of the mold insert, including features like cooling channels and undercuts, which can affect the cycle time and quality of the finished part. Additionally, the compatibility of the insert with the chosen injection molding machine should be evaluated to avoid operational issues. It is crucial to engage with experienced manufacturers who can provide insights on the optimal insert configurations tailored to specific production needs and materials used in the injection molding process.

Understanding Different Types of Injection Mold Inserts and Their Applications

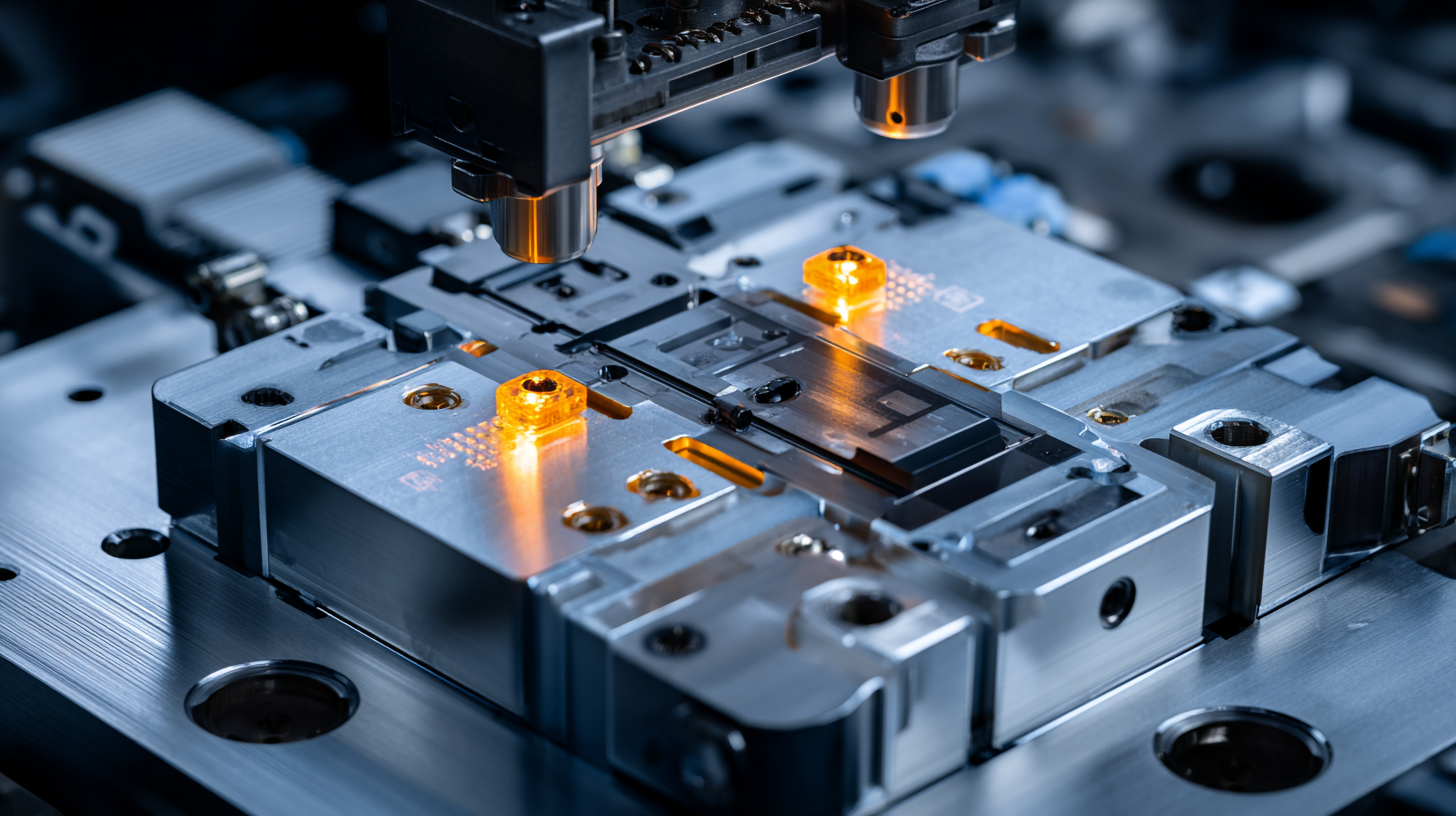

When selecting injection mold inserts for manufacturing processes, understanding the various types and their applications is crucial. Injection mold inserts can generally be classified into core inserts, cavity inserts, and hot runner inserts, each serving distinct purposes in the molding process. According to a report by Grand View Research, the global injection molding market is expected to reach USD 452.9 billion by 2027, underscoring the importance of choosing the right inserts to enhance efficiency and product quality.

Core inserts are primarily used to create internal features within molded parts, which can add complexity and efficiency to the design. Cavity inserts, on the other hand, are crucial for forming the outer shape of the product. Recent data from MarketsandMarkets highlights that advancements in insert technology are driving industry growth, with companies reporting up to 30% reduction in production times when utilizing high-quality insert designs.

Furthermore, hot runner inserts significantly improve material flow and reduce waste, leading to a more sustainable manufacturing process. As industries increasingly focus on efficiency and sustainability, understanding these distinct insert types will empower manufacturers to make informed decisions tailored to their specific needs.

Evaluating Material Compatibility for Long-Lasting Mold Inserts

When selecting injection mold inserts for manufacturing, evaluating material compatibility is crucial for achieving durability and performance. According to a report by Grand View Research, the global injection molding market is projected to reach $355.4 billion by 2027, emphasizing the industry's growing importance. Choosing the right materials can significantly impact the lifespan and effectiveness of the mold inserts. For instance, steel and aluminum are common choices; steel offers greater strength and wear resistance, while aluminum is lighter and more cost-effective for shorter production runs.

In addition to mechanical properties, it is essential to consider the thermal behavior of the materials used for mold inserts. A study by the Plastics Industry Association highlights that materials with lower thermal expansion coefficients provide better dimensional stability, which is vital during the injection molding process. Selecting high-performance polymers for inserts, such as P20 or H13 tool steel, can yield enhanced resistance to deformation and improved surface finish quality. The right material selection not only enhances the production efficiency but also reduces downtime and maintenance costs for manufacturers, leading to a more profitable operation.

Cost-Effectiveness: Balancing Quality and Budget in Mold Insert Choices

When it comes to selecting injection mold inserts, cost-effectiveness plays a crucial role in ensuring that manufacturers maximize their return on investment. Balancing quality and budget involves a thorough analysis of material choices, manufacturing processes, and the anticipated lifecycle of the mold inserts. High-quality materials may come with a higher initial cost, but their durability and performance can lead to reduced downtime, fewer defects, and consequently lower long-term operational costs.

Moreover, understanding the specific requirements of the application is essential. For instance, if a particular project demands intricate designs or high precision, opting for premium-grade inserts could prove beneficial despite the higher price tag. On the other hand, for projects with less stringent requirements, selecting economical options may suffice without compromising the overall production quality. By carefully evaluating the intended application alongside budget constraints, manufacturers can make informed decisions that align with their operational goals while ensuring cost-effectiveness in their mold insert choices.

Future Trends in Injection Mold Insert Technology for Enhanced Production Efficiency

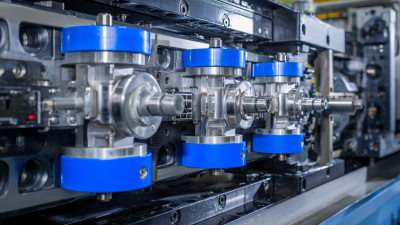

As the manufacturing industry evolves, injection mold insert technology is witnessing significant advancements aimed at enhancing production efficiency. One of the key trends is the integration of smart technologies that provide real-time data analytics. These smart molds can monitor processing conditions, allowing for immediate adjustments that reduce waste and optimize production cycles. Manufacturers adopting these technologies can enhance their operational capabilities and remain competitive in a fast-paced market.

Tip: Consider investing in injection molds equipped with IoT capabilities. These smart systems can lead to substantial reductions in downtime by alerting operators to potential issues before they escalate.

Another emerging trend is the use of advanced materials, such as lightweight composites and high-performance alloys, to produce more durable mold inserts. These materials not only extend the lifespan of molds but also enable higher production rates without sacrificing quality. By leveraging these advancements, manufacturers can meet increasingly demanding specifications while reducing overall costs.

Tip: Evaluate your current mold materials and explore options that enhance longevity and thermal stability, ensuring your molds can handle diverse production requirements effectively.

Related Posts

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing

-

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

-

Exploring the Benefits of Home Plastic Injection Molding: A Deep Dive into Efficiency and Innovation

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair