2025 How to Choose the Right Injection Tooling for Your Manufacturing Needs

In the realm of modern manufacturing, the choice of the right injection tooling can significantly influence both the efficiency of production and the quality of the final product. According to industry expert Dr. Emily Carter, a leading authority in injection molding technology, "The right tooling is not just an asset; it's a cornerstone for achieving excellence in manufacturing." As businesses strive for innovation and operational efficiency, understanding the intricacies of injection tooling becomes paramount.

Injection tooling encompasses a range of considerations, from material selection to design intricacies and cost-efficiency. Each decision made in the tooling process can affect production timelines, product consistency, and overall profitability. In an evolving market where speed and precision are critical, manufacturers must align their injection tooling strategies with their specific needs to ensure they remain competitive. By considering these factors thoughtfully, companies can optimize their production capabilities and lay the groundwork for future success.

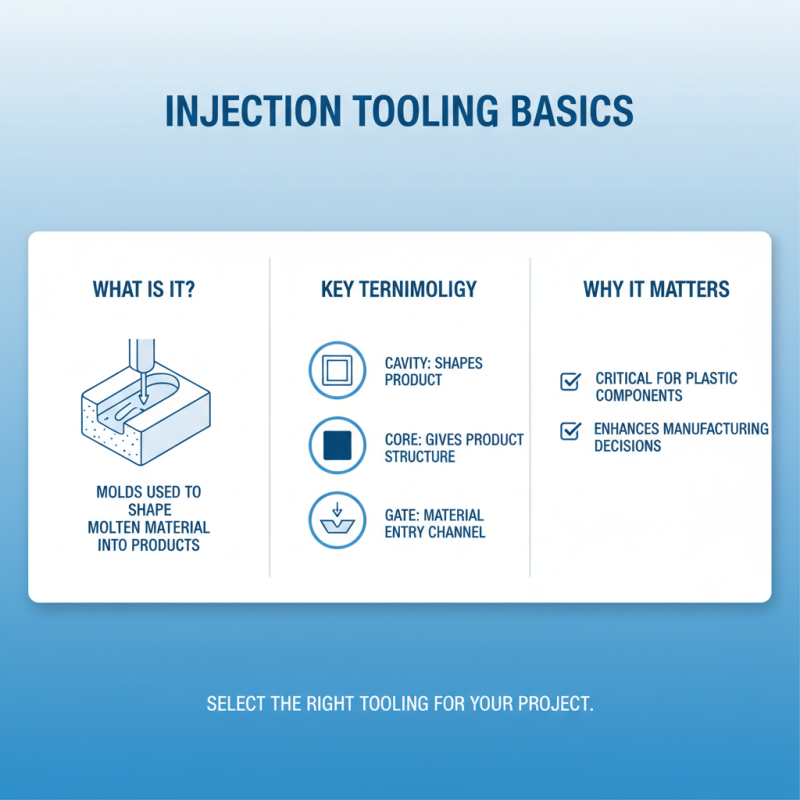

Understanding Injection Tooling Basics and Terminology

Injection tooling is a critical aspect of the manufacturing process, particularly in producing plastic components. Understanding the basics and terminology associated with injection tooling can significantly enhance decision-making when selecting the right tooling for specific project needs. At the core, injection tooling refers to the molds used in the injection molding process, where molten material is injected into a mold cavity to create products. Familiarity with terms like “cavity,” “core,” and “gate” is essential. The cavity is the hollow part of the mold that shapes the final product, while the core is the solid part that gives the product its structure. Gates are the channels through which the molten material enters the mold.

Another important concept is the distinction between single-cavity and multi-cavity molds. Single-cavity molds produce one part at a time, making them suitable for lower volume production runs, while multi-cavity molds can produce several parts simultaneously, increasing efficiency for higher volume needs. Additionally, there are considerations regarding material selection for the tooling itself, typically ranging from aluminum to steel, depending on the durability and production volume required. Understanding these fundamentals helps manufacturers assess their specific needs and make informed choices about the tooling that will yield the best results for their production requirements.

Identifying Your Manufacturing Requirements and Specifications

When selecting the right injection tooling for your manufacturing needs, it is crucial to first identify your manufacturing requirements and specifications. A comprehensive understanding of the materials you intend to use, part complexity, volume production requirements, and tolerance levels is essential. According to a recent report from the International Journal of Advanced Manufacturing Technology, over 60% of production delays in the injection molding process are attributed to inadequate tooling specifications. This highlights the importance of aligning tooling design closely with the desired outcomes of your production process.

Additionally, consider the expected lifecycle of your products. For high-volume production, investing in high-quality, durable tooling can reduce per-part production costs significantly. The American Society of Mechanical Engineers reports that optimized tooling for injection molding can lead to a 30-50% reduction in cycle times, thus increasing overall efficiency. Thoroughly assessing factors such as weight, size, and geometric complexity will ensure that the tooling you select is not only cost-effective but also capable of meeting the demanding production standards of today’s competitive market. Careful planning at this stage can lead to improved product quality and increased profitability.

Evaluating Material Compatibility with Different Tooling Options

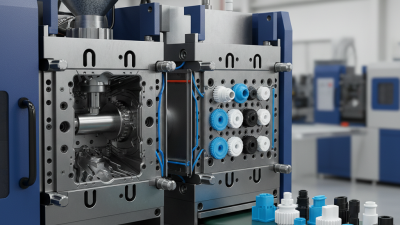

When selecting the right injection tooling for manufacturing needs, a critical factor to consider is material compatibility. Different materials require specific tooling designs, and understanding these requirements can significantly impact product quality and production efficiency. For instance, materials with high viscosity may necessitate tooling with larger gates and flow channels to ensure proper filling. On the other hand, delicate materials require tooling that minimizes shear stress to prevent degradation.

Tips: Always conduct thorough material research before finalizing tooling options. Consider factors such as temperature tolerance, chemical resistance, and mechanical properties of the materials you plan to process. Additionally, prototype testing can help identify compatibility issues early in the process, saving time and resources down the line.

It's also essential to consider the tooling material itself. Tooling made from harder metals can withstand wear from abrasive materials, while aluminum may be more suitable for lower-volume runs with less wear. The selection of the correct tooling material can enhance durability and achieve better production results. Always consult with technical experts who understand both the materials and tooling capabilities for tailored advice that suits your specific manufacturing requirements.

Analyzing Cost-Effectiveness and Long-Term Value of Tooling

When selecting the right injection tooling for your manufacturing needs, analyzing cost-effectiveness and long-term value is critical. The upfront investment in tooling can be significant, so it's essential to consider not just the initial costs, but also how these tools will perform over time. Higher-quality tools often come with a better warranty and longer lifespan, reducing the frequency of replacements. Additionally, efficient tooling can lead to shorter cycle times and fewer defects, which can substantially save costs during production.

**Tips:** One tip is to conduct a thorough analysis of your expected production volume and cycle times. This can help you determine whether to invest in high-quality, durable tooling or opt for more economical options that may require more frequent replacements. Also, consider the material compatibility with your products, as this can significantly influence the tool's lifespan and performance.

Furthermore, it’s essential to factor in maintenance costs, as a well-maintained tool can provide better ROI by maintaining production efficiency. Look for tooling solutions that offer easy maintenance or support. Investing a little extra in tooling that simplifies maintenance can lead to long-term savings and improved productivity in your manufacturing process.

Selecting Reliable Suppliers and Manufacturers for Injection Tooling

When selecting reliable suppliers and manufacturers for injection tooling, it is crucial to consider their experience and expertise in the industry. According to the latest report from Mordor Intelligence, the global injection molding market is expected to reach $340 billion by 2025, driven by advancements in technology and increased demands for lightweight materials in various sectors. Therefore, partnering with manufacturers who have a proven track record and a deep understanding of the latest materials and techniques can significantly enhance product quality and efficiency in production.

Moreover, assessing the manufacturing capabilities of suppliers is vital. A study by Grand View Research indicates that the use of advanced manufacturing technologies, such as 3D printing and automated systems, can reduce lead times by up to 30%. Therefore, seeking out suppliers that utilize these technologies can not only streamline the production process but also ensure consistency in the quality of the injection tooling produced. Additionally, evaluating customer reviews and obtaining references from other manufacturers can provide valuable insight into the reliability and performance of potential suppliers, helping to make informed decisions that align with your manufacturing needs.

2025 Injection Tooling Supplier Evaluation

Related Posts

-

How to Choose the Right Injection Mold Inserts for Your Manufacturing Needs

-

What is Plastic Injection Mold? A Comprehensive Guide for Beginners

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Top 10 Advantages of the Plastic Injection Moulding Process You Need to Know

-

How to Achieve Super Finishing for Enhanced Surface Quality in Manufacturing

-

Why is Surface Finishing Process Essential for Product Quality?