2026 How to Choose the Right Injection Mold Tooling for Your Project?

Choosing the right injection mold tooling is crucial for successful production. According to industry expert John Smith, “The right tooling can make or break a project.” His insight highlights the importance of careful selection. Manufacturing processes rely heavily on precision and quality.

When deciding on injection mold tooling, it’s essential to consider numerous factors. Material choice, production volume, and design complexity play critical roles. For instance, a project requiring high precision may need advanced tooling. However, achieving this can be costly and time-consuming.

Ignoring these factors can lead to production delays and increased costs. Often, businesses focus only on the budget, overlooking quality. As John emphasizes, "Don't sacrifice quality for cost." Reflecting on past projects can provide valuable lessons. Selecting the right injection mold tooling demands a balance of quality, efficiency, and cost-effectiveness to ensure lasting success.

Identifying Your Project Requirements for Injection Molding

When embarking on an injection molding project, it’s crucial to clearly identify project requirements. Start by defining product specifications. Consider the dimensions, materials, and tolerances necessary. Industry reports indicate that 70% of injection molding failures stem from unclear specifications. Without a clear plan, costs can escalate and timelines can extend.

Collaboration with your design team is key. Engage them early to discuss constraints and capabilities. Remember, designs may need adjustments for manufacturability. A report from the Society of Plastics Engineers states that modifying a poorly designed mold can increase costs by up to 30%. Ensure that all stakeholders are aligned on goals.

Tips: Be flexible in your design. Sometimes, initial ideas require changes for efficiency. Additionally, consider the production volume. Low volumes may justify simpler tooling, while high volumes benefit from more complex designs. Always keep manufacturing techniques in mind when brainstorming.

Iterate on your requirements. Mistakes will happen; reflection is part of the process. Continuous feedback from the production floor can lead to improvements. Aim for clarity, but be prepared to adapt as your project evolves.

Understanding Different Types of Injection Mold Tooling

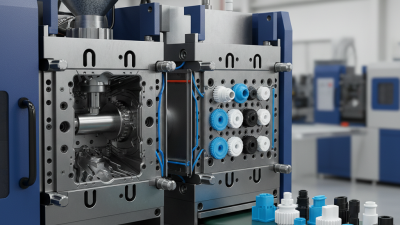

When choosing injection mold tooling, understanding the types is crucial. There are several options available. Each type serves different needs and projects. A commonly used type is the steel mold. It’s durable and can handle high volumes of production. However, it can be expensive and time-consuming to create.

Another option is aluminum molds. These are lighter and quicker to manufacture. They work well for lower production runs. Yet, they may not last as long as steel molds. This can lead to higher maintenance costs over time.

In addition, one might consider prototype molds. They are perfect for testing designs. These molds allow adjustments before full-scale production. However, they can lead to confusion about design stability. Understanding the pros and cons of each type is key. Molds can drastically affect production quality and cost.

Understanding Different Types of Injection Mold Tooling

This chart illustrates various types of injection mold tooling and their uses in projects, showcasing the percentage of applications for each type in the industry.

Evaluating Material Choices for Mold Construction

When selecting the right material for mold construction, the choices can be overwhelming. For injection molding, common materials include steel and aluminum. Steel offers durability and longevity, but it is more expensive. Aluminum is lighter and easier to machine, yet it may wear out faster. Depending on your project needs, the choice becomes critical.

Consider the complexity of your design. A complex mold often requires robust materials. However, using heavy-duty materials may increase costs significantly. Testing prototypes can help. But, not all designs get the same results. You might find issues only during production. This can lead to frustration and additional costs.

Another crucial factor is the production volume. For low-volume projects, fast machining materials can be beneficial. However, for high-volume runs, durability takes precedence. This can be a tricky balance. Many engineers face challenges when navigating material properties. Creating molds is often an iterative process. Reflection on past projects can guide future choices.

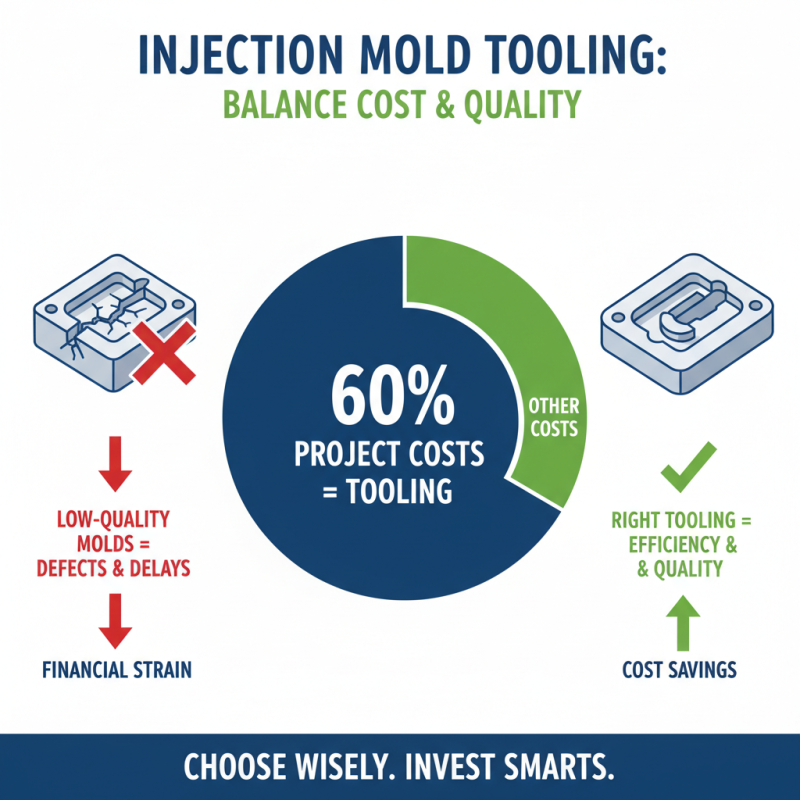

Assessing Cost vs. Quality in Mold Tooling Selection

Choosing the right injection mold tooling is crucial. It's a balance between cost and quality. A recent industry report shows that about 60% of project costs are attributed to tooling. This is significant. Many projects feel the financial strain of low-quality molds. They can lead to defects and increased production time.

Quality molds often have a higher upfront cost. However, they offer longevity and consistent performance. According to injection molding specialists, high-quality tooling can reduce cycle times by up to 20%. That reduction contributes to overall savings, despite initial expenses. Conversely, cheap molds might require frequent replacements. Each retooling brings its own costs, which can quickly add up.

It's essential to assess your specific project needs. Consider the production volume and complexity. For lower volumes, cost-effective tooling may suffice. However, for high-volume runs, investing in quality pays off. Many companies struggle with this decision. The right tool can make or break a project. Evaluating both cost and quality takes time and a careful look at your goals.

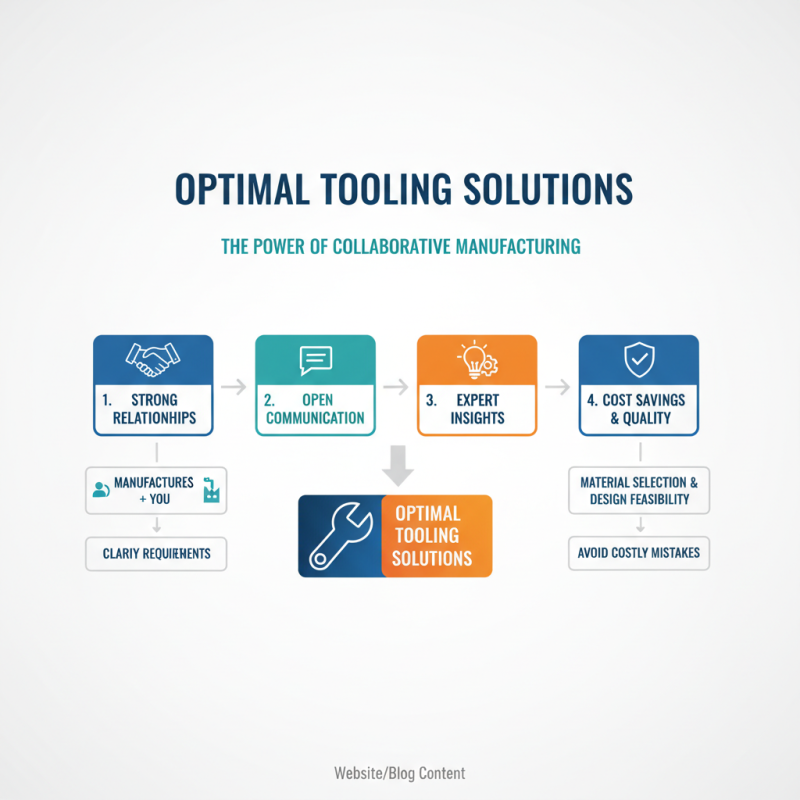

Collaborating with Manufacturers for Optimal Tooling Solutions

Collaborating with manufacturers is vital for achieving optimal tooling solutions. Building a strong relationship can lead to better communication. Open dialogue helps clarify project requirements and expectations. Manufacturers can provide valuable insights into material selection and design feasibility. This helps avoid costly mistakes later in production.

It's essential to share accurate specifications with manufacturers. Providing detailed blueprints can streamline the design process. However, misunderstandings may still occur. Regular check-ins are necessary to ensure everything stays on track. Listening to feedback and being open to adjustments can enhance the outcome. Often, it's the minor tweaks that make a big difference in the final product.

Navigating tooling challenges often requires a team effort. Manufacturers may suggest improvements based on their experience. This collaboration can help identify potential issues early. Acknowledging past mistakes can guide better decision-making in future projects. Seeking multiple opinions strengthens the foundation for success. Efficient tooling isn't just about machinery; it's about people working together.

Related Posts

-

Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes

-

Top 10 Advantages of the Plastic Injection Moulding Process You Need to Know

-

What is Plastic Injection Mold? A Comprehensive Guide for Beginners

-

2025 How to Choose the Right Injection Tooling for Your Manufacturing Needs

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

What Are the Top Manufacturing Technology Trends for 2026?