How to Choose the Right Plastic Injection Tooling for Your Project?

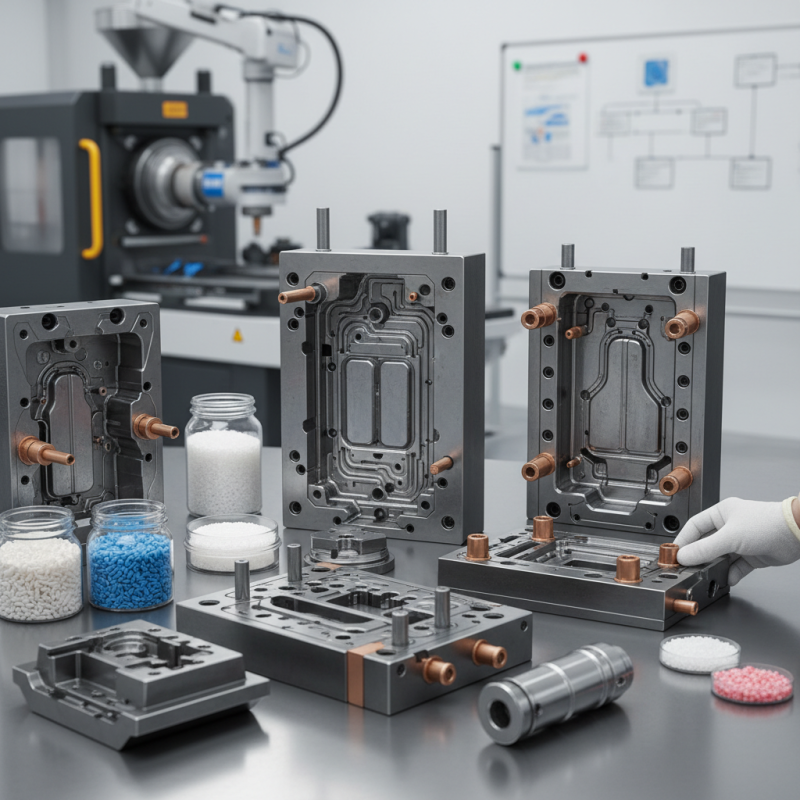

Choosing the right plastic injection tooling for your project is crucial. Accurate tooling affects product quality and production efficiency. Many factors influence this decision, including material, complexity, and budget. Improper choices can lead to significant delays and increased costs.

When considering plastic injection tooling, it's essential to assess your project's specific needs. Is your design complex? What type of plastic will you use? These questions guide your tooling selection. A well-designed tool yields better parts and fewer defects. Yet, many overlook the importance of optimizing their tooling choices.

Reflecting on past projects can be beneficial. What worked well? What didn't? Learning from experiences helps improve future decisions. While finding the perfect tooling may seem daunting, understanding its significance can lead you to better results.

Understanding the Importance of Plastic Injection Tooling in Manufacturing

Plastic injection tooling plays a crucial role in modern manufacturing processes. This technique is vital for producing a wide variety of plastic parts used in numerous industries. According to industry reports, around 70% of plastic products are made using injection molding. Therefore, the right tooling can significantly impact production efficiency and product quality.

Understanding tooling materials is essential. Common choices include aluminum and steel, each with distinct pros and cons. Aluminum is lighter and more affordable, suitable for short runs. Steel, on the other hand, lasts longer and can handle complex designs. However, it comes at a higher initial investment. Reports suggest that improper material selection can lead to increased costs and production delays, as manufacturers often overlook this detail.

Moreover, the design of the tooling influences the overall success of a project. Draft angles, wall thickness, and cooling channels must align with the final part specifications. Some engineers rush through design, neglecting vital calculations. This can lead to defects and wasted materials. Insights from research indicate that approximately 30% of design iterations result from tooling-related issues. Investing time in proper design pays off in the long run.

How to Choose the Right Plastic Injection Tooling for Your Project?

| Factor | Importance Level | Considerations |

|---|---|---|

| Material Type | High | Choose a material that matches the end product's requirements (e.g., durability, flexibility). |

| Tooling Complexity | Medium | Consider the design's complexity; more intricate designs may require advanced tooling. |

| Production Volume | High | Estimate the number of parts needed; higher volumes may justify more investment in tooling. |

| Cost Efficiency | High | Evaluate the cost of tooling versus the profitability of the project. |

| Lead Time | Medium | Account for the time required to design and manufacture the injection molding tools. |

| Mold Maintenance | Medium | Consider how easy it is to maintain the mold and how frequently it will require servicing. |

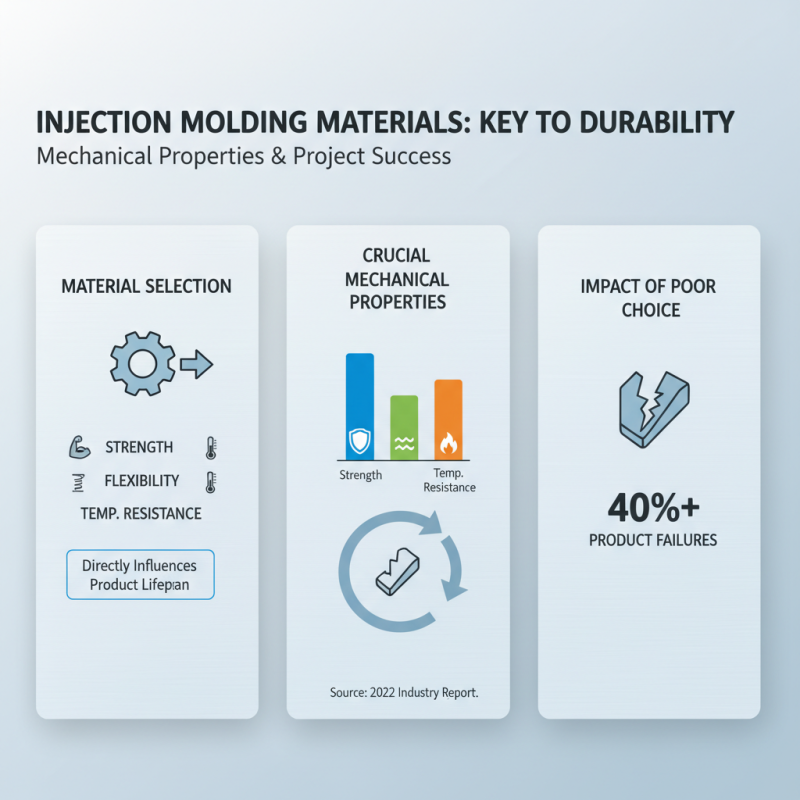

Key Factors to Consider When Selecting Injection Molding Materials

Choosing the right injection molding materials is crucial for project success. One key factor to consider is the material’s mechanical properties. Strength, flexibility, and temperature resistance directly influence durability. For instance, according to a 2022 industry report, over 40% of product failures relate to inadequate material selection.

Another aspect to ponder is the environment where the product will be used. Products exposed to chemicals or extreme temperatures need specialized materials. Reports show that almost 30% of failed designs stem from neglecting environmental conditions. It's vital to match material properties with these real-world applications.

**Tip:** Always test materials under real conditions before finalizing your choice. This can prevent costly mistakes.

Cost is another vital consideration. While some materials may seem cheaper upfront, long-term performance can lead to higher costs. According to research, 50% of manufacturers reported increased expenses from using low-quality materials in their projects.

**Tip:** Assess the total lifecycle cost of materials. It’s a smart financial strategy.

Selecting the right materials requires careful thought. Misjudgments can lead to product failures and wasted resources. Take the time to analyze and choose wisely.

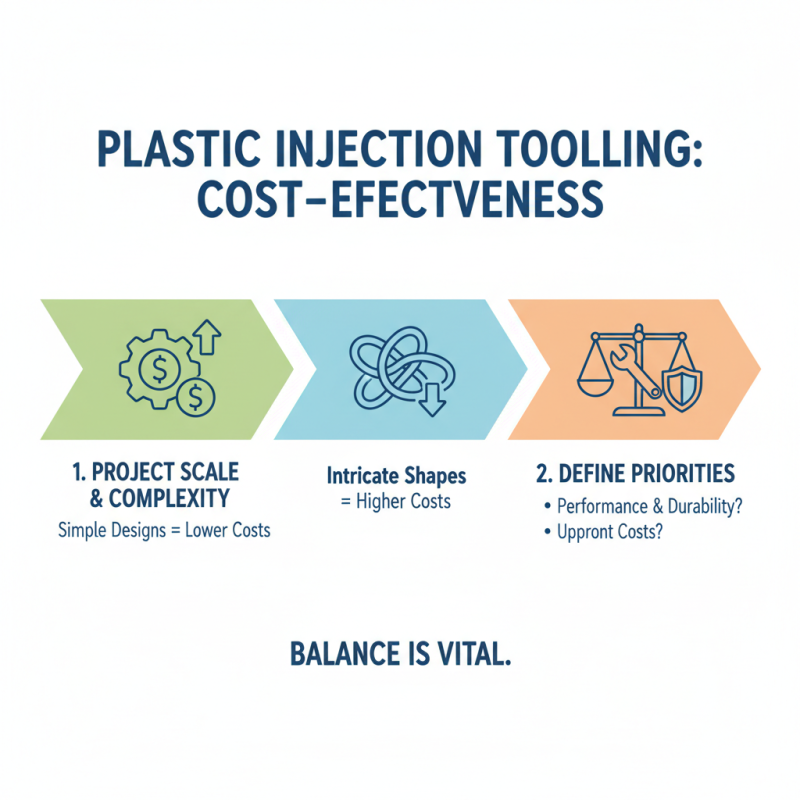

Evaluating the Cost-Effectiveness of Different Tooling Options

When considering tooling options for plastic injection, cost-effectiveness is crucial. Start by assessing the project’s scale and complexity. Simplistic designs usually lead to lower tooling costs. However, intricate shapes may increase expenses significantly. It’s essential to define your priorities. Are performance and durability more important than upfront costs? Understanding this balance is vital for your decision-making process.

Next, evaluate material choices for the tooling. Steel lasts longer but costs more initially. Aluminum is more affordable but might wear out faster. Think about how many parts you need to produce. If it's a large volume, investing in durable steel tooling makes more sense. Sometimes, companies rush to pick the cheaper option without analyzing long-term benefits. This could lead to higher replacement costs.

Don’t overlook maintenance and production downtime. Inexpensive tooling might save money up front but can lead to issues later. Poor performance can stall production and increase costs in ways you didn’t anticipate. Taking time to reflect on past projects could provide insights. Learn from previous experiences to guide your tooling choices effectively. Balancing initial investment with long-term benefits is key to a successful project.

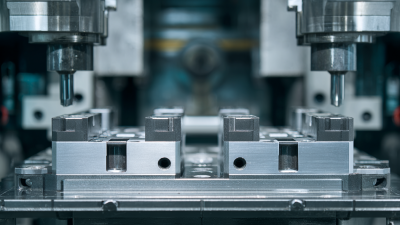

Assessing Tolerance and Precision Requirements for Your Project

When selecting plastic injection tooling, tolerance and precision are crucial. Understanding how tight these tolerances need to be can influence your entire project. For instance, an automotive part might require tight tolerances to ensure a perfect fit. On the other hand, a simple casing might allow for more lenient specifications.

Consider the materials involved. Different plastics behave uniquely under varying temperatures and pressures. Some materials might expand or contract significantly, which could affect precision. Identifying these factors early can save time and money. It’s also vital to work closely with your tooling provider to confirm that the designs can meet the necessary standards.

Keep in mind that perfection is hard to achieve. Even with precise calculations, human error can creep in. Regular checks during the production process are essential. If you spot inconsistencies, reflect on the tooling decisions made. Are the tolerances too tight? Or perhaps the tooling was not calibrated properly? Answering these questions helps improve future projects.

Plastic Injection Tooling Tolerance and Precision Requirements

This chart illustrates the tolerance requirements for different precision levels in plastic injection tooling. Precise tooling generally requires tighter tolerances (e.g., 0.01%), while lower precision may allow for more considerable variations (up to 0.1%). Understanding these requirements is crucial to selecting the right tooling for your project.

The Role of CAD and Simulation Technologies in Tooling Design Decisions

Designing plastic injection tooling is complex. CAD and simulation technologies play a crucial role in this process. They help visualize tooling concepts before physical production begins. This reduces costly mistakes later on. Tools can be adjusted easily in a virtual environment. Designers can iterate rapidly to find the best solution.

Simulation technologies provide valuable insights. They allow teams to test various parameters, such as cooling times and material flow. However, it's essential to remember that simulations might not always mimic real-life scenarios. Unexpected issues can arise during actual injection molding. A balance between simulation results and hands-on testing is necessary.

Collaboration among team members is vital. Designers, engineers, and manufacturers should communicate openly. CAD files must be clear and detailed. Sometimes, misinterpretations happen. Feedback loops can help catch potential flaws early in the design process. The goal is to create tooling that meets both performance and budget constraints.

Each project offers lessons. Reflecting on past decisions can lead to better outcomes in future tooling designs.

Related Posts

-

2025 How to Choose the Right Injection Tooling for Your Manufacturing Needs

-

What is Plastic Injection Mold? A Comprehensive Guide for Beginners

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

How to Choose the Right Injection Mold Inserts for Your Manufacturing Needs