How to Choose the Right Stamping Dies for Your Metalworking Projects

When embarking on a metalworking project, the choice of the right stamping dies can significantly influence both the efficiency of the process and the quality of the final product. Stamping dies are essential tools that shape, cut, or form metal components through high-pressure techniques, making them critical for achieving precise results. Understanding the nuances of selecting the appropriate stamping dies will not only streamline your workflow but also enhance the overall performance of your creations.

Choosing the right stamping dies involves a comprehensive evaluation of several factors, including material compatibility, the complexity of designs, and production volume requirements. The diverse range of available stamping dies means that metalworkers must consider the specific demands of their projects to ensure optimal results. Additionally, this decision process can impact cost-effectiveness and production timelines. By understanding the key elements involved in selecting stamping dies, metalworkers can better align their tools with their project goals, leading to improved outcomes and greater satisfaction with their endeavors.

Understanding Different Types of Stamping Dies for Metalwork

When it comes to metalworking projects, understanding the various types of stamping dies is crucial for achieving the desired results. Stamping dies can be broadly categorized into different types, including progressive dies, single-station dies, and compound dies. Progressive dies are particularly beneficial for mass production, as they allow for multiple operations in a single pass, which can greatly enhance efficiency. They are ideal for projects that require complex shapes and high volumes, making them a preferred choice in automotive and electronics manufacturing.

On the other hand, single-station dies are typically used for standalone tasks, such as cutting or forming a single part. These dies are best suited for small-scale projects or prototypes where flexibility and precision are more critical than volume. Compound dies combine operations in one process, executing both cutting and forming simultaneously, which helps to minimize production time and labor costs. By understanding the functional differences between these die types, metalworkers can select the most appropriate option based on their specific project requirements, ultimately leading to more effective and efficient results.

How to Choose the Right Stamping Dies for Your Metalworking Projects

| Die Type | Material Used | Typical Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Flat Dies | Carbon Steel | Sheet metal stamping | Cost-effective; easy to produce | Limited to flat shapes |

| Progressive Dies | Tool Steel | Complex part shapes | High production efficiency; versatile | Higher initial costs |

| Single-Action Dies | Aluminum | Simple forming operations | Simple design; quick setup | Limited to basic shapes |

| Compound Dies | High-Speed Steel | Bending and cutting operations | Reduces cycle time; less material waste | Complex maintenance |

| Custom Dies | Various Metals | Specific needs and custom designs | Tailored for unique projects | Higher cost and longer lead time |

Evaluating Material Compatibility for Stamping Dies

When selecting stamping dies for your metalworking projects, one of the most crucial factors to consider is material compatibility. The effectiveness of a stamping die largely depends on how well it can work with the specific metal or alloy being used. Different materials possess unique properties, such as hardness, tensile strength, and ductility, which directly influence the wear and tear of the die during the stamping process. For instance, softer metals may require less robust dies, whereas harder materials may necessitate dies made from higher-grade steel or carbide to withstand increased stress.

Moreover, the thickness and type of metal to be stamped impact the choice of die design. Thicker metals can lead to greater pressure and require dies designed to handle higher loads. Additionally, the type of stamping operation—whether it be progressive, transfer, or single-operation stamping—will require careful evaluation of material compatibility to ensure optimal performance and longevity of the dies. Conducting thorough research on the material properties and consulting with experienced professionals can guide you in selecting the right combination of stamping dies that align with your project requirements, minimizing downtime and enhancing productivity.

Material Compatibility for Stamping Dies

This chart evaluates the compatibility of different materials for stamping dies based on a rating system from 0 to 10, where higher values indicate better compatibility for metalworking projects.

Assessing Die Design Options Based on Project Requirements

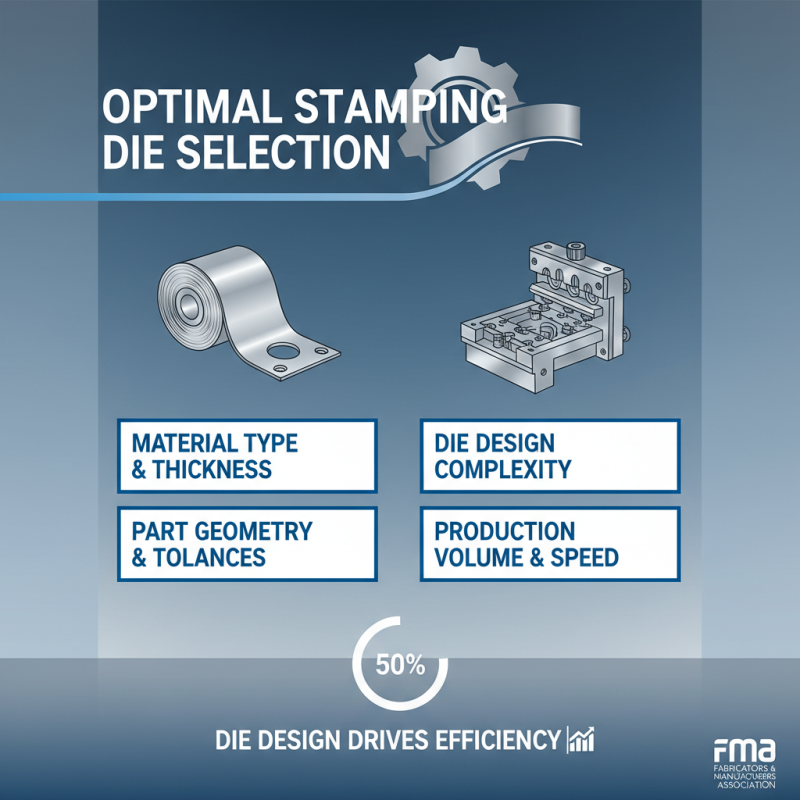

When it comes to selecting the right stamping dies for your metalworking projects, one of the most critical factors to consider is the design options that align with your specific project requirements. Understanding the nature of the materials you are working with and the intricacies of the die design is essential. According to a recent industry report by the Fabricators & Manufacturers Association, nearly 50% of manufacturers cite die design as a determining factor for production efficiency and quality. Therefore, taking the time to assess your project's needs can significantly impact your operational success.

Different projects necessitate distinct die designs based on factors such as material thickness, complexity of shapes, and production volume. For instance, progressive dies are ideal for high-volume production where multiple operations occur in one stroke, while single-operation dies serve better for simpler tasks. A comprehensive study by the American Society of Mechanical Engineers highlights that utilizing the right die design can reduce scrap rates by up to 30%, emphasizing the importance of careful evaluation. Additionally, project timelines play a crucial role; opting for custom dies designed specifically for your application can significantly speed up production cycles, ensuring that timelines are met efficiently.

Considering Production Volume and Cost Efficiency

When selecting stamping dies for metalworking projects, understanding production volume and cost efficiency is crucial. Production volume dictates the type of die that will be most beneficial. For small runs or prototyping, a simple, less expensive die may suffice. However, if your project entails a large volume of parts, investing in more robust, precision-engineered dies may be warranted. High-volume production often benefits from progressive dies, which can operate at higher speeds and provide greater precision, resulting in lower per-unit costs.

Cost efficiency is equally important when choosing stamping dies. An initial high expenditure on a die that offers longevity and performance can lead to savings over time, especially in large production settings. It’s essential to gauge the return on investment by considering factors such as die life, maintenance needs, and the cost of raw materials. Additionally, analyzing the total cost of ownership, which includes the expenses associated with setup, operation, and potential downtimes, can inform choices that ultimately enhance productivity while keeping budgets in check. Balancing initial costs with long-term benefits will guide metalworking professionals in selecting dies that align with their operational goals.

Maintenance and Longevity of Stamping Dies in Metalworking

Proper maintenance of stamping dies is essential for maximizing their lifespan and ensuring optimal performance in metalworking projects. Regular inspection and cleaning are crucial steps that help in detecting wear and tear early, preventing costly repairs. Ensure that the dies are free of debris and corrosion, as contaminants can affect their functionality and precision. A routine cleaning schedule should be established, utilizing appropriate solvents that will not harm the die material.

Tips:

1. Always lubricate the dies before use to minimize friction and reduce wear. This simple step can significantly extend their operational life.

2. Store dies in a dry and controlled environment, away from moisture and extreme temperatures, to prevent rust and degradation.

Additionally, it’s important to keep the operational pressures within the manufacturer’s recommended limits. Overloading the dies can lead to premature failure or deformation. Regularly applying maintenance checks, including the inspection of alignment and support components, ensures that any issues are addressed before they escalate and affect production quality. Keeping detailed records of maintenance routines can also aid in identifying patterns of wear and predicting when replacements may be necessary, ultimately improving the overall efficiency of your metalworking processes.

Related Posts

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

Why Super Finishing Is Essential for Achieving a Surface Roughness of Up to Ra 0.1µm

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

How to Choose the Right Bevel Gears for Your Precision Engineering Needs

-

Understanding the Future of Plastic Components in Sustainable Manufacturing Processes

-

Exploring the Benefits of Home Plastic Injection Molding: A Deep Dive into Efficiency and Innovation