How to Choose the Right Machining Tools for Your Project Success

Choosing the right machining tools is crucial for the success of any manufacturing project. According to a recent report by the International Manufacturing Technology Show (IMTS), the global machining tools market is projected to reach $70 billion by 2025, underscoring the importance of selecting tools that not only meet project specifications but also enhance efficiency and productivity. With an expansive range of options available, understanding the specific capabilities and limitations of each type of machining tool is essential for achieving optimal results.

Expert opinions further highlight the significance of informed decision-making in this area. Renowned machining tools specialist Dr. Emily Jenkins states, “The choice of the right machining tools can significantly impact both the quality of the finished product and the overall project timeline.” She emphasizes the need to consider factors such as material compatibility, precision requirements, and production volume when selecting tools. As manufacturing continues to evolve, equipping oneself with the knowledge of current trends and technological advancements in machining tools becomes imperative for project managers and engineers alike.

Understanding the Different Types of Machining Tools Available Today

When embarking on a machining project, understanding the different types of machining tools available is crucial for achieving optimal results. Machining tools can be broadly categorized into cutting tools, shaping tools, and finishing tools. Cutting tools, such as drills and lathes, are designed to remove material from a workpiece. These tools come in various shapes and sizes, tailored to specific operations like drilling holes or shaping edges. Material selection for cutting tools is also vital, as tools made from high-speed steel or carbide each have their own advantages depending on the project requirements.

Shaping tools, on the other hand, are primarily used to create specific forms and contours on a workpiece. Examples include milling machines and grinders, which allow for precise shaping and surface smoothing. The choice of shaping tools often depends on the complexity of the desired shape and the material being processed.

Lastly, finishing tools aim to enhance the surface quality of the final product. These tools, which may include sanders and polishers, ensure that the finished item meets the required specifications for smoothness and appearance. By understanding the characteristics and applications of these diverse machining tools, you can make informed decisions that align with your project goals and ensure successful outcomes.

Key Factors to Consider When Selecting Machining Tools for Your Project

When selecting the right machining tools for your project, several key factors should be considered to ensure the success of your operations. First and foremost, the material you are working with plays a crucial role in tool selection. Different materials, whether they are metals, plastics, or composites, require specific types of tools designed for optimum cutting efficiency and durability. Understanding the properties of the material will help you choose tools that can handle the required speeds and feeds without wearing out prematurely.

Another important factor is the complexity of the components being machined. Projects that involve intricate designs or tight tolerances will benefit from precision tools and advanced machining techniques. Establishing the necessary level of precision early in the planning process will guide you in selecting tools that can achieve those specifications while minimizing the need for rework. Additionally, consider the available machinery and the compatibility of the tools with your equipment. Ensuring that the tools are designed to work with your existing setup can greatly enhance productivity and reduce downtime.

Evaluating Material Compatibility: Matching Tools with Workpieces

When selecting machining tools for your project, ensuring material compatibility is crucial to achieving optimal results. The relationship between tools and workpieces, dictated by material properties, plays a significant role in machining efficiency, tool longevity, and overall project success. Industry studies indicate that approximately 30% of machining issues stem from mismatched materials and tooling, leading to increased production costs and waste.

Understanding the material composition of both the tool and the workpiece can prevent these complications. For instance, high-speed steel (HSS) tools are typically well-suited for softer metals like aluminum; however, when machining harder materials such as titanium, carbide tools may be necessary due to their superior hardness and wear resistance. A report from the International Journal of Advanced Manufacturing Technology revealed that using the correct tool material can enhance tool life by up to 200% when compared to inappropriate tool selections.

Moreover, factors such as thermal conductivity, toughness, and brittleness must be evaluated. According to a survey by the American Society of Mechanical Engineers, selecting tools based on the machinability of the workpiece material can lead to a 25% increase in productivity rates. In essence, thorough knowledge of material compatibility is not merely a technical requirement; it is a strategic approach that can significantly influence the efficiency and success of machining projects.

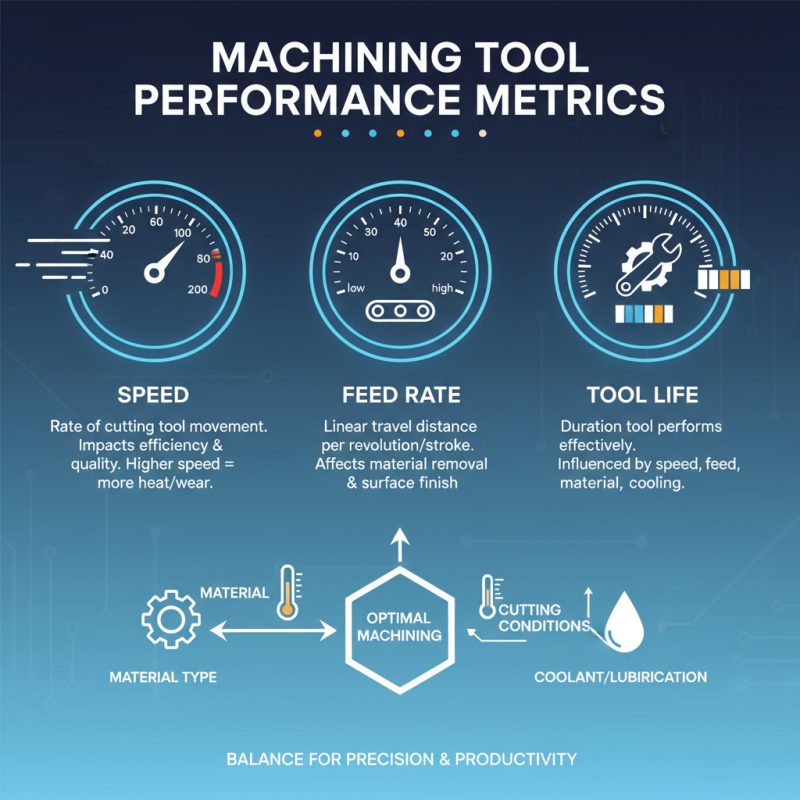

Assessing Tool Performance Metrics: Speed, Feed Rate, and Tool Life

When selecting machining tools for a project, it is crucial to assess their performance metrics, particularly speed, feed rate, and tool life. Speed refers to the rate at which the cutting tool moves through the material, and it significantly impacts the efficiency and quality of the machining process. Higher speeds can enhance productivity but may also lead to increased heat generation and tool wear if not managed properly. Therefore, understanding the optimal speed for different materials and cutting conditions is essential in achieving the desired results without compromising tool integrity.

Feed rate, the distance the tool advances during each revolution or cycle, plays a vital role in determining the surface finish and overall machining accuracy. A higher feed rate increases productivity but risks compromising the quality of the finished part. Conversely, a slower feed rate can enhance detail and precision but may prolong machining time. It's essential to find a balance that aligns with the specifications of the project while considering the capabilities of the chosen tools.

Lastly, tool life—the duration a tool remains effective before replacement—is another critical metric in tool selection. Longer tool life often translates to lower overall costs and less downtime in manufacturing processes. Factors influencing tool life include material compatibility, cutting conditions, and maintenance practices. By carefully evaluating these performance metrics, manufacturers can choose the right machining tools that not only meet the technical demands of their projects but also ensure optimal efficiency and cost-effectiveness.

Budgeting for Machining Tools: Cost-Effectiveness and Investment Return

When budget planning for machining tools, it's crucial to strike a balance between cost-effectiveness and long-term investment returns. Assessing the scale and requirements of your project can guide you in selecting tools that not only fit your budget but also enhance productivity. Investing in high-quality, durable tools may cost more upfront but can lead to significant savings over time, as they often require less maintenance and fewer replacements.

**Tips:** Consider the specific materials and techniques you'll be using. This can help narrow down the necessary tools and avoid overspending on features you won't utilize. Additionally, seek out vendors that offer comprehensive packages or discounts for bulk purchases, which can significantly bring down your overall costs.

Moreover, creating a detailed cost analysis for each type of tool can aid in making informed decisions. Look beyond the initial purchase price; account for operational costs, potential wastage, and the lifespan of the tools. By prioritizing tools that offer a good return on investment, you can ensure that every dollar spent contributes positively to your project's success.

**Tips:** Keep track of tool performance metrics to evaluate which tools provide the best value over time. This data can help refine future budgeting decisions and guide you in selecting tools that align with both your financial and operational goals.

How to Choose the Right Machining Tools for Your Project Success - Budgeting for Machining Tools: Cost-Effectiveness and Investment Return

| Tool Type | Average Cost ($) | Material Compatibility | Expected Lifespan (Hours) | Return on Investment (%) |

|---|---|---|---|---|

| End Mill | 150 | Aluminum, Steel | 300 | 200 |

| Lathe Tool | 200 | Steel, Brass | 250 | 180 |

| Drill Bit | 50 | Wood, Plastic, Aluminum | 150 | 220 |

| Router | 120 | Wood, Composite | 200 | 210 |

| Saw Blade | 80 | Wood, Metal | 350 | 190 |

Related Posts

-

What is Micro Machining? A Comprehensive Guide to Its Techniques and Applications

-

What is Injection Molded Parts and How They are Made

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

10 Essential Tips for Selecting Titanium Alloy: Insights from Industry Experts and Market Trends

-

Understanding the Plastic Injection Moulding Process: A Comprehensive Guide for Beginners

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025