How to Effectively Use Plastic Components in Sustainable Manufacturing 2025

In the pursuit of sustainable manufacturing practices, the effective utilization of plastic components has become increasingly vital. As industries face mounting pressure to minimize their environmental impact, the integration of advanced plastic materials offers a promising solution. Renowned expert in sustainable materials, Dr. Emily Carter, states, "The future of manufacturing lies in our ability to innovate with plastic components that not only meet performance demands but also align with ecological responsibilities." This insight underscores the critical role that thoughtfully designed plastic components play in reducing waste and enhancing the lifecycle of products.

As we approach 2025, the manufacturing landscape is evolving, calling for practices that embrace sustainability without compromising quality. Plastic components, when used judiciously, can significantly contribute to lighter, more durable products while also enabling recycling and reusability initiatives. This transition hinges on collaboration across sectors, where engineers, designers, and environmentalists unite to redefine the boundaries of traditional manufacturing. In the following sections, we will explore strategies and innovations that can enhance the sustainable use of plastic components, paving the way for a greener future in manufacturing.

Understanding the Role of Plastic Components in Sustainable Manufacturing

The role of plastic components in sustainable manufacturing is increasingly critical as industries look for ways to reduce their environmental impact while maintaining efficiency and productivity. Plastics, when sourced sustainably and designed for recyclability, can contribute to a circular economy. For instance, bioplastics derived from renewable resources minimize reliance on fossil fuels, reducing greenhouse gas emissions during production. Moreover, advancements in recycling technologies enable manufacturers to recycle plastic components, extending their lifecycle and reducing waste.

Additionally, the integration of plastic components in product design allows for lightweight alternatives, which can lead to decreased energy consumption during transportation. Innovative manufacturing techniques, such as injection molding using recycled materials, can also enhance the performance of products while minimizing environmental harm. By prioritizing the use of sustainable plastics and employing responsible manufacturing practices, companies can effectively leverage plastic’s versatility while supporting sustainable development goals in 2025 and beyond.

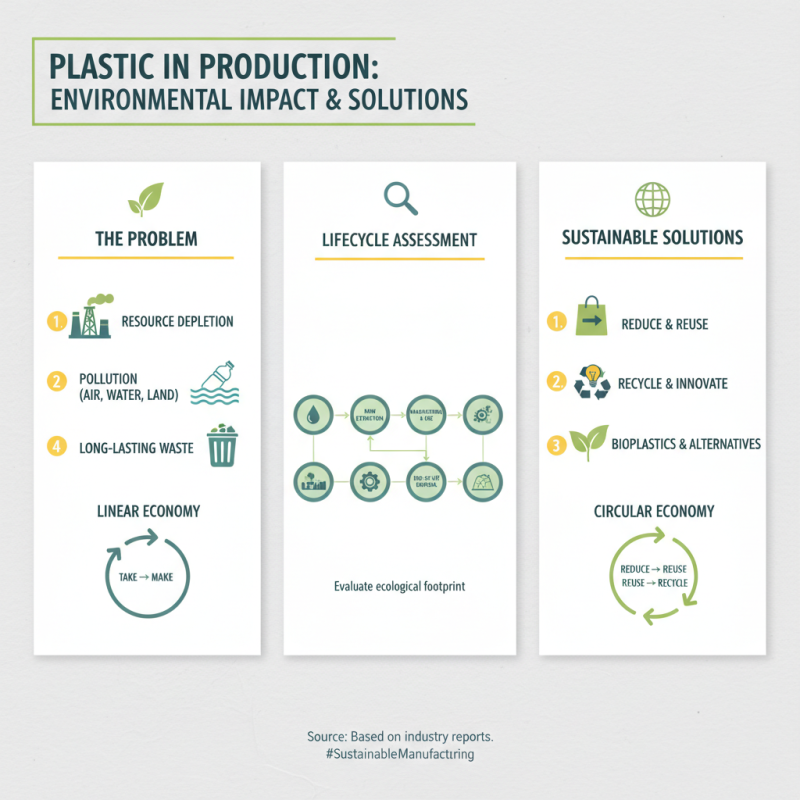

Assessing the Environmental Impact of Plastic in Production Processes

The environmental impact of plastic in production processes is a pressing concern as industries strive for sustainable manufacturing practices. While plastic materials offer versatility and durability, their contribution to pollution and resource depletion cannot be overlooked. Companies must assess the full lifecycle of plastic components, from raw material extraction to disposal, to understand their ecological footprint and make informed decisions.

**Tips:** One effective strategy is to conduct regular lifecycle assessments (LCAs) to evaluate the environmental effects of plastic use throughout production stages. Engaging in material substitution, where sustainable alternatives replace traditional plastics, can also mitigate negative impacts. Additionally, investing in recycling technologies allows manufacturers to reclaim and reuse plastic, significantly reducing waste and promoting a circular economy.

Ultimately, fostering collaboration between manufacturers, suppliers, and researchers is crucial in addressing these challenges. Sharing best practices and innovations can lead to more sustainable solutions and a collective effort towards minimizing the production impact on the environment. By taking these proactive steps, industries can strike a balance between utilizing plastic components and safeguarding our planet for future generations.

Innovative Techniques for Recycling and Reusing Plastic Materials

Innovative techniques for recycling and reusing plastic materials are essential in the pursuit of sustainable manufacturing. One promising method involves chemical recycling, which breaks down plastic waste into its original monomers, enabling the creation of high-quality new plastics. This process not only reduces the amount of waste sent to landfills but also conserves the fossil fuels typically required for virgin plastic production. By integrating chemical recycling into manufacturing processes, companies can significantly minimize their environmental footprint while maintaining the integrity and functionality of their products.

Another effective approach to enhancing sustainability is the implementation of modular design principles. By designing plastic components that can be easily disassembled and reused, manufacturers can facilitate easier recycling and extend the lifecycle of their products. For instance, using standardized parts across multiple product lines allows for the economical harvesting of materials when products reach the end of their useful life. This technique encourages a circular economy where plastics are kept in use for as long as possible, reducing the demand for new plastic production and decreasing overall environmental impact. These innovative strategies showcase how manufacturers can transition towards more sustainable practices through thoughtful design and advanced recycling technologies.

Best Practices for Selecting Sustainable Plastic Alternatives

As the world moves towards sustainable manufacturing, selecting sustainable plastic alternatives is crucial for the future. The disposable cup and lid market, particularly those made from bioplastics and plant fibers, is experiencing significant growth, driven by consumers' increasing awareness of environmental issues. By 2033, this market is projected to expand considerably, influenced by applications in food and beverage processing, food service, and retail. Companies are urged to adopt best practices in sourcing materials that minimize environmental impact, thereby aligning with sustainable packaging trends.

To support this transition, initiatives such as using recyclable materials and optimizing packaging solutions are essential. As seen in the eco-friendly straw market, which is expected to grow from $4.59 billion in 2024 to $9.98 billion by 2035, there is a clear demand for innovative, sustainable options. This growth highlights a broader shift towards circular economy practices, where materials are reused and recycled, reducing waste and ecological footprints. Industries must prioritize the adoption of sustainable materials in their products, which ultimately benefits the environment and meets the evolving consumer preferences for greener alternatives.

Future Trends in Plastic Usage for Eco-Friendly Manufacturing Solutions

As we look to the future of sustainable manufacturing, the trends in plastic usage indicate a significant shift towards eco-friendly solutions. By 2032, the global market for polylactic acid (PLA) is expected to reach an impressive $4.22 billion, growing at a compound annual growth rate (CAGR) of 16.3%. This growth underscores the increasing demand for biodegradable materials in manufacturing processes. Companies are realizing the importance of integrating sustainable options without compromising product quality.

Tips for Implementation:

- Choose Biodegradable Materials: Consider incorporating PLA and other biodegradable plastics into your products to meet consumer demand for sustainability.

- Embrace Innovations in Composites: Explore the applications of wood-plastic composites, which are projected to grow at a CAGR of 8.57%. This innovative blend not only enhances durability but also supports eco-friendly initiatives.

As enterprises adapt to stricter environmental regulations, the sustainable packaging equipment market is expected to see substantial growth. Valued at $157.6 billion by 2024, with a CAGR of 7.3% anticipated, this market reflects a trend where companies prioritize eco-friendly packaging solutions. The increasing insistence on recyclable packaging forms from consumers further emphasizes this shift.

Tips for Packaging Solutions:

- Invest in Sustainable Packaging Technologies: Look into cutting-edge packaging solutions that align with sustainability goals, ensuring compliance with emerging regulations.

- Focus on Recyclability: Select materials that are not just eco-friendly but also easily recyclable, enhancing your brand’s commitment to sustainability and attracting environmentally conscious consumers.

Related Posts

-

Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing

-

Exploring Innovation: How Plastic Industries are Shaping Sustainable Technology for the Future

-

Exploring the Future of Plastic Parts: Innovations Shaping Tomorrow's Manufacturing

-

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

-

2025 Top Machining Tools: Revolutionizing Precision and Efficiency in Manufacturing

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing