How to Choose the Right Ejector Pins for Your Injection Molding Projects

In the realm of injection molding, selecting the right components can significantly impact the quality and efficiency of production. Among these critical components, ejector pins play a pivotal role in the successful ejection of molded parts from their cavities. As noted by industry expert John Smith, "The performance of your injection mold is only as good as the precision and reliability of your ejector pins." This statement encapsulates the essence of how integral these components are in ensuring smooth operation and minimizing production setbacks.

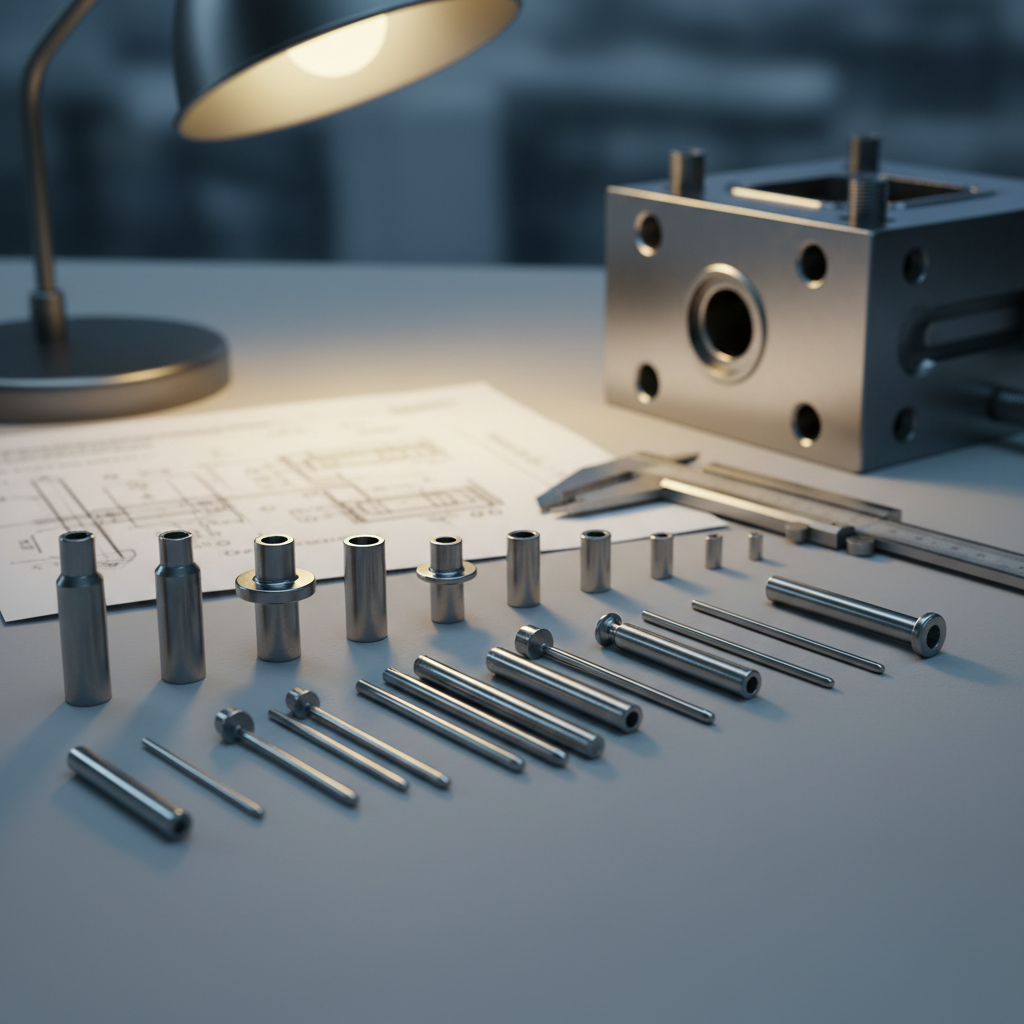

Choosing the appropriate ejector pins involves careful consideration of various factors, including material, length, and diameter. With the right selection process, manufacturers can avoid common pitfalls such as pin breakage or inadequate ejection force, thus enhancing overall productivity. This article will explore the top ten considerations when selecting ejector pins for your injection molding projects, aiming to provide a comprehensive guideline to improve both the quality of molded parts and the effectiveness of the molding process. By understanding the nuances of ejector pin selection, you can ensure that your projects are executed seamlessly and deliver the desired results.

Understanding the Importance of Ejector Pins in Injection Molding

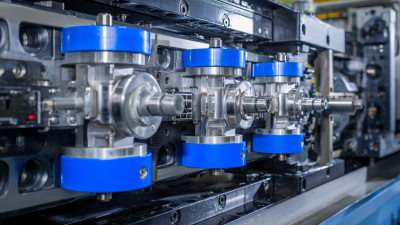

Ejector pins play a critical role in injection molding, acting as the mechanism that ejects the finished parts from the mold. The importance of these pins cannot be overstated, as they must ensure proper venting to prevent gas traps and enable smooth removal of the molded components. A recent study indicates that optimizing ejector pin configurations can significantly reduce the effective demolding forces (EDFs) required, with potential reductions of up to 30%, particularly when using designs that incorporate advanced features like InnoVent technology.

When selecting ejector pins, several key factors should be considered. First, the material properties of the ejector pins are crucial — high-strength, wear-resistant materials tend to improve longevity and performance. Second, the pin diameter and stroke length must be tailored to match the specific geometry of the mold to minimize stress during ejection.

Tips for Success:

- Always assess the surface finish of the injection mold, as rough surfaces can increase friction and lead to higher demolding forces.

- Consider utilizing ejector accelerators for parts requiring additional pin travel; this can enhance the efficiency of the ejection process without the need for secondary ejector plates, further streamlining production timelines.

Key Factors to Consider When Selecting Ejector Pins

When selecting ejector pins for injection molding projects, several key factors play a crucial role in ensuring optimal performance and efficiency. Firstly, the material of the ejector pins is paramount. Pins made from high-speed steel or stainless steel are often preferred due to their durability and resistance to wear. According to industry data, pins with superior hardness can last up to 50% longer than standard options, thereby reducing costs in the long run.

Moreover, the dimensions and design of the pins should align with the specific requirements of your mold. For instance, tapered ejector pins can facilitate the easy removal of parts from complex molds. It's essential to consider the balance between ejector pin size and the thickness of the mold's walls, as this can significantly impact the ejection force required.

Tips: Always consult the manufacturer's specifications and machine requirements before selecting your ejector pins, and don't overlook the importance of the coating options available, as certain coatings can improve resistance to corrosion and enhance the overall life cycle of the pins. Additionally, understanding the cooling and heating conditions of your mold can influence which ejector pin design will best serve your project needs.

Types of Ejector Pins and Their Suitable Applications

When selecting ejector pins for injection molding, it is essential to consider the various types available and their specific applications. Standard ejector pins are typically used for general purposes, providing reliable ejection for simple geometries. On the other hand, specialized ejector pins, such as those with tapered or threaded designs, are ideal for more complex shapes that require precise ejection force and alignment.

Understanding the part design and the material being used can help in choosing the right type of ejector pin to ensure optimal performance.

Additionally, it's crucial to consider the sizing of ejector pins in relation to the overall tooling layout, particularly concerning gates, runners, and sprues. Properly sized gates and runners can significantly affect how ejector pins perform during the molding process. Ensuring these components are proportionate and harmonized with the ejector pin design can lead to a smoother operation and reduce the risk of defects. By carefully assessing the type and size of ejector pins alongside the molding system, manufacturers can enhance the efficiency and quality of their injection molding projects.

Common Materials for Ejector Pins and Their Benefits

When selecting ejector pins for your injection molding projects, understanding the common materials available can significantly influence the quality and efficiency of your production. The most frequently used materials include tool steel, stainless steel, and aluminum. Tool steel, known for its hardness and durability, is an excellent choice for high-production runs, as it withstands wear and extends the lifespan of the pins. Stainless steel, while slightly softer, offers excellent corrosion resistance, making it ideal for projects that involve reactive materials or humid environments.

Tips: When working with stainless steel ejector pins, consider applying a protective coating to further enhance their durability. For projects requiring precise tolerance, selecting tool steel pins with heat treatment can provide added strength and stability.

Aluminum ejector pins, although less commonly used, can be advantageous for low-volume production or prototyping. Their lightweight nature allows for easier handling and quicker machining processes. Additionally, the lower cost of aluminum can make it an economical choice for certain applications. However, be mindful of their lower wear resistance, which may necessitate more frequent replacements.

Tips: For prototypes, try using aluminum pins for their ease of modification. Ensure you maintain a suitable storage environment to prevent corrosion on steel options, regardless of the material chosen.

Best Practices for Maintaining Ejector Pins in Molding Processes

Maintaining ejector pins effectively is crucial for the success of injection molding projects. According to a study by the Injection Molding Association, improper maintenance of ejector pins can lead to a decrease in mold lifespan by nearly 30%. Regular inspection and timely replacement of worn-out pins can significantly enhance mold performance and reduce unexpected downtime. It is recommended to develop a standardized maintenance schedule that includes cleaning, lubrication, and visual inspections to identify any deformities or corrosion early on.

Lubrication plays a key role in the longevity of ejector pins, as friction during the molding process can cause wear over time. Data from a 2022 report by Plastics Technology highlights that using high-quality lubricants can extend the life of ejector pins by up to 25%. Additionally, employing protective coatings can further safeguard against wear and tear. By investing in proper maintenance practices and utilizing advanced materials, manufacturers can ensure their ejector pins remain in optimal condition, ultimately leading to improved production efficiency and reduced costs.

How to Choose the Right Ejector Pins for Your Injection Molding Projects - Best Practices for Maintaining Ejector Pins in Molding Processes

| Ejector Pin Material | Hardness (HRC) | Corrosion Resistance | Typical Application |

|---|---|---|---|

| Tool Steel | 50 - 60 HRC | Moderate | General Injection Molding |

| Stainless Steel | 30 - 50 HRC | High | Food and Medical Applications |

| Bronze | 25 - 40 HRC | Moderate | Low-Friction Applications |

| P20 Steel | 28 - 32 HRC | Low | Standard Injection Molding |

| Aluminum | 20 - 40 HRC | High | Lightweight Products |

Related Posts

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

Exploring the Benefits of Home Plastic Injection Molding: A Deep Dive into Efficiency and Innovation

-

Exploring the Future of Plastic Parts: Innovations Shaping Tomorrow's Manufacturing

-

Understanding the Future of Plastic Components in Sustainable Manufacturing Processes

-

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications