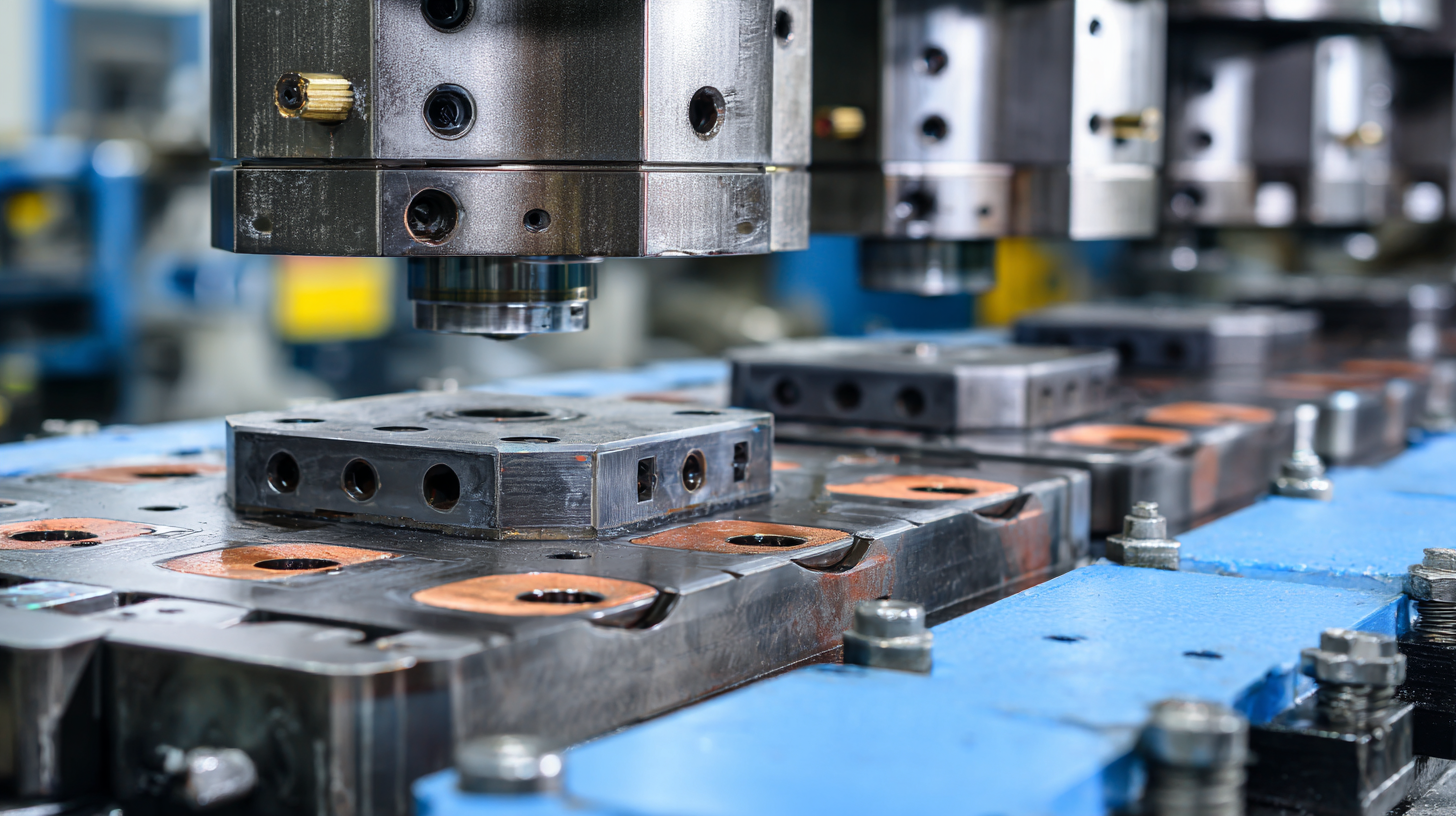

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

The evolution of stamping dies in the metal forming industry has been marked by significant innovations and trends aimed at enhancing efficiency and precision in manufacturing processes. According to a recent market report by Grand View Research, the global metal stamping market is projected to reach USD 261.36 billion by 2025, driven by the increasing demand for lightweight and durable materials in the automotive and aerospace sectors. Stamping dies, as a critical component in this industry, play a pivotal role in optimizing product design and reducing production costs. Innovations such as computer-aided design (CAD) and the integration of advanced materials have transformed the capabilities of stamping dies, enabling manufacturers to produce complex shapes with higher accuracy and faster turnaround times. This article delves into the advancements in stamping dies, exploring how these developments shape the future of metal forming processes and contribute to the competitive edge of businesses operating in this dynamic landscape.

The Historical Background of Stamping Dies in Metal Forming

The historical background of stamping dies in the metal forming industry is rich and multifaceted, tracing back to the early days of industrialization. Initially, metal forming relied heavily on manual processes using simple tools for shaping metal.

By the late 19th century, advancements in mechanization led to the introduction of more sophisticated dies, which allowed for greater precision and efficiency in mass production. This marked a significant turning point in manufacturing, as companies began to recognize the advantages of using stamping dies to produce high volumes of uniform metal parts.

As the 20th century progressed, the evolution of stamping dies continued to be influenced by technological innovations, such as computer-aided design (CAD) and computerized numerical control (CNC) systems. These advancements enabled manufacturers to design and fabricate intricate dies with enhanced capabilities for complex geometries and tighter tolerances. The integration of automation and robotics further transformed the stamping process, reducing labor costs and increasing production speeds. This historical progression not only highlighted the need for improved design and materials but also underscored the competitive advantage that efficient stamping die technology could provide to manufacturers within the rapidly advancing metal forming industry.

Emerging Technologies Shaping the Future of Stamping Dies

The stamping dies used in the metal forming industry have witnessed significant advancements, largely driven by emerging technologies. One of the most impactful innovations is the adoption of computer-aided design (CAD) software, which allows engineers to create precise and complex die geometries. This technological leap enhances the efficiency of the design process and minimizes material waste, making it more sustainable. Additionally, advancements in simulation software enable companies to predict how materials will behave during the stamping process, reducing trial-and-error setups and leading to faster production times.

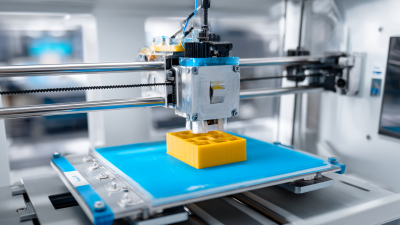

Another area of growth is the utilization of additive manufacturing for creating stamping dies. This method allows for the production of intricate designs that were previously impossible or too costly to manufacture using traditional methods. The ability to produce custom die components on-demand not only reduces lead times but also enables companies to adapt more swiftly to market changes and client demands. Furthermore, innovations in materials science have led to the development of stronger and lighter die materials, which enhance the lifespan and performance of stamping tools. As these technologies continue to evolve, they promise to reshape the metal forming industry, driving greater efficiency and precision in stamp die production.

The Evolution of Stamping Dies in the Metal Forming Industry

This chart illustrates the investment trends in stamping die technologies within the metal forming industry from 2018 to 2023. A clear upward trajectory can be observed, indicating a growing focus on innovation and modernization in the stamping die sector.

Sustainability Practices in Die Manufacturing and Metal Forming

In recent years, the metal forming industry has seen a significant shift towards sustainability in die manufacturing processes. According to a report by the Metal Stamping Association, nearly 50% of manufacturers are now incorporating eco-friendly materials and processes, which has led to a reduction in carbon emissions by 30% over the past five years. The integration of recycled alloys not only minimizes waste but also preserves natural resources, aligning with the industry's goal of achieving a circular economy.

Innovations in manufacturing techniques have also played a pivotal role in enhancing sustainability. For instance, advancements in additive manufacturing, or 3D printing, allow for the production of stamping dies that consume less material and energy compared to traditional methods. A study from the International Journal of Advanced Manufacturing Technology highlighted that these new techniques can reduce production costs by up to 20% while improving part quality and longevity. This dual benefit showcases how the industry is not only focused on efficiency but also on fostering an environmentally responsible approach in die manufacturing.

The Role of Automation and AI in Stamping Die Design

The integration of automation and artificial intelligence (AI) into stamping die design is transforming the metal forming industry. Traditionally, stamping die design relied heavily on manual processes, which often resulted in longer lead times and increased chances of human error. However, with the advent of sophisticated software and automated tools, designers can now create complex die geometries with enhanced precision. This shift not only streamlines the design process but also contributes to the production of higher-quality components that meet the stringent demands of modern manufacturing.

AI plays a pivotal role in optimizing stamping die design by utilizing advanced algorithms to predict die performance and material behaviors. Machine learning models can analyze vast datasets from previous stamping operations to identify patterns and inefficiencies, allowing for continuous improvement. Furthermore, AI-driven simulations enable designers to test various scenarios in a virtual environment, minimizing the risk of costly material waste and reducing the number of physical prototypes required. As a result, manufacturers benefit from faster turnaround times and increased competitiveness in the market.

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations - The Role of Automation and AI in Stamping Die Design

| Aspect | Traditional Methods | Current Trends | Future Innovations |

|---|---|---|---|

| Design Process | Manual CAD drafting | Parametric design software | AI-driven generative design |

| Production Speed | Time-consuming manual adjustments | Automated machine setups | Real-time adaptive changes via AI |

| Material Utilization | High scrap rates | Improved simulation for material flow | AI optimization algorithms for minimal waste |

| Maintenance | Reactive maintenance schedules | Predictive maintenance using sensors | AI predictive analytics for preemptive actions |

| Customization | Limited customization options | Modular die components | Full customization through AI design |

Trends in Material Selection for Enhanced Die Performance

In the ever-evolving metal forming industry, the selection of materials for stamping dies is critical for enhancing die performance. Recent trends indicate a shift towards advanced materials that offer improved durability and resistance to wear, thus extending the lifespan of dies. For instance, the integration of multifunctional materials, inspired by nature's designs, is becoming increasingly popular in die manufacturing. These innovations not only enhance mechanical properties but also allow for the creation of dies that can perform multiple functions, reducing the need for multiple dies and streamlining production processes.

Moreover, the advent of multi-material additive manufacturing plays a significant role in this evolution. The ability to combine various materials at the manufacturing stage enables the production of complex geometries that were previously unattainable. This technique enhances die performance by leveraging the strengths of different materials, allowing for superior heat management and increased precision in forming processes. As the industry continues to explore these cutting-edge approaches, the focus remains on improving the sustainability and efficiency of stamping dies through innovative material selections.

Related Posts

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025