The Future of Micro Machining Technologies Driving Precision Engineering Innovations

The future of micro machining technologies is poised to revolutionize precision engineering, with rapid advancements driving innovation across various industries. According to a report by Markets and Markets, the global micro machining market is projected to reach USD 3.24 billion by 2025, growing at a CAGR of 8.7% from 2020. This incredible growth is fueled by the increasing demand for miniaturized components in sectors such as aerospace, medical devices, and electronics, where precision is paramount.

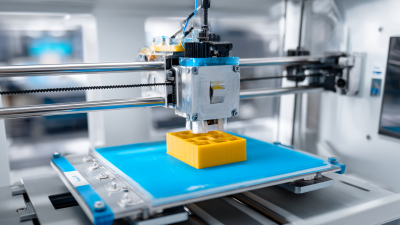

As micro machining techniques evolve, they enable the creation of intricate geometries and complex features that were previously unattainable with traditional manufacturing methods. With the integration of smart manufacturing and automation technologies, the potential for further enhancements in precision and efficiency in micro machining is enormous. This essay will delve into the latest developments in micro machining technologies and explore their implications for the future of precision engineering.

As micro machining techniques evolve, they enable the creation of intricate geometries and complex features that were previously unattainable with traditional manufacturing methods. With the integration of smart manufacturing and automation technologies, the potential for further enhancements in precision and efficiency in micro machining is enormous. This essay will delve into the latest developments in micro machining technologies and explore their implications for the future of precision engineering.

Understanding Micro Machining Technologies in Precision Engineering

Micro machining technologies have revolutionized precision engineering, enabling the creation of intricate components with unparalleled accuracy. With the global micro machining market expected to reach $4.5 billion by 2025, driven by advancements in materials and manufacturing processes, it is important to understand the underlying technologies. Techniques such as laser machining, electrical discharge machining (EDM), and micro milling are leading this evolution, delivering precision that meets the demanding requirements of sectors like aerospace, medical devices, and electronics.

When integrating micro machining into your engineering projects, consider these tips: First, assess the material properties of your components, as different materials require specific machining methods for optimal results. Second, invest in quality software solutions that enhance the programming and simulation of micro machining processes, ensuring efficiency and reducing waste. Finally, stay updated on emerging technologies; for instance, the introduction of hybrid machining systems that combine different methods can significantly improve productivity and precision.

As we delve deeper into the realm of micro machining, understanding these technologies becomes essential for driving innovations in precision engineering. The adaptability and flexibility of micro machining not only enable bespoke solutions but also pave the way for future advancements in automation and process control within the industry.

Key Innovations Shaping the Future of Micro Machining

As micro machining technologies continue to evolve, several key innovations are significantly shaping the future of precision engineering. One of the most exciting advancements is the integration of automation through smart manufacturing systems. Utilizing artificial intelligence and machine learning, these systems can optimize machining processes in real time, leading to unprecedented levels of efficiency and accuracy. By minimizing human intervention, manufacturers can reduce errors and enhance production speed, allowing for higher-quality components even at smaller scales.

Another important innovation is the development of advanced materials and coatings that improve tool life and performance. These materials enable micro machining operations to handle tougher substrates without compromising precision. Furthermore, innovations such as multi-axis machining and hybrid manufacturing techniques are expanding the capabilities of micro machining. These technologies allow for the simultaneous processing of complex geometries, enhancing design flexibility and ushering in new possibilities across industries like aerospace, medical devices, and electronics. As these innovations continue to gain traction, the landscape of precision engineering is set to transform dramatically, opening doors to new applications and efficiencies.

Applications of Micro Machining in Various Industries

The micromachining market is set for significant growth, with projections suggesting an increase from USD 3.71 billion in 2025 to USD 6.01 billion by 2033, representing a compound annual growth rate (CAGR) of 6.2%. This growth is largely driven by a wide array of applications across different industries. In sectors such as healthcare, the demand for precision machining is paramount, particularly in the production of medical implants. The Medical Implants Precision Machining Service Market is projected to reach USD 1,964.5 million by 2035, indicating a CAGR of 6.4%.

Additionally, advancements in laser micromachining techniques are revolutionizing traditional manufacturing processes. These techniques allow for the creation of intricate features on a micro and nanoscale with remarkable precision. As industries seek to raise productivity through enhanced precision and flexibility, the global micromachining equipment market is also experiencing considerable growth, expected to expand from USD 3,296.5 million in 2024 to USD 5,638.2 million by 2033. These trends highlight the essential role that micro machining technologies play in driving innovations in precision engineering across various sectors.

The Future of Micro Machining Technologies Driving Precision Engineering Innovations

| Industry | Application | Machining Technology | Precision Level (µm) | Market Growth (%) |

|---|---|---|---|---|

| Electronics | Micro Components | Laser Machining | 10 | 7 |

| Medical Devices | Surgical Tools | EDM (Electrical Discharge Machining) | 5 | 8 |

| Aerospace | Component Manufacturing | Micro Milling | 8 | 6 |

| Automotive | Precision Parts | Ultrasonic Machining | 12 | 5 |

| Optics | Lens Manufacturing | Wire EDM | 4 | 10 |

Challenges and Solutions in Advanced Micro Machining Techniques

The field of micro machining technologies is at the forefront of precision engineering, but it is not without its challenges. One of the primary issues faced by engineers is the increasing complexity of designs that demand higher precision and accuracy. This necessitates the development of advanced machining techniques that can maintain quality while achieving micro-scale tolerances. For instance, traditional machining processes often struggle with the intricacies of tiny features, leading to errors that can accumulate and compromise the final product.

To address these challenges, innovative solutions are being explored. The integration of machine learning algorithms and real-time data analytics can predict potential failures in the machining process, enabling operators to optimize parameters dynamically. Additionally, the use of advanced materials such as ceramics and composites has proven beneficial in improving durability and performance. Moreover, incorporating automated systems with robotic technology can enhance the precision and speed of micro machining tasks, significantly reducing human error and increasing production efficiency. This synergy of technology and engineering expertise is paving the way for a new era of micro machining that promises to revolutionize various industries.

The Role of Automation and AI in Enhancing Micro Machining Precision

Automation and artificial intelligence (AI) are revolutionizing the field of micro machining, significantly enhancing precision and efficiency in manufacturing processes. By integrating advanced algorithms and machine learning techniques, companies are now able to optimize machining parameters in real time, ensuring that products meet the strictest tolerances required in precision engineering. This convergence of technology allows for smarter tools that can adjust to varying materials and operational conditions, thus minimizing waste and improving overall production quality.

Moreover, AI-driven predictive maintenance systems can foresee equipment failures before they occur, resulting in reduced downtime and lower maintenance costs. These innovations not only improve the reliability of micro machining equipment but also facilitate rapid prototyping and customization, enabling manufacturers to respond swiftly to market demands. As the micromachining equipment market is expected to grow significantly in the coming years, the integration of AI and automation will undoubtedly play a crucial role in shaping the future of precision engineering, driving advancements that were previously unimaginable.

The Future of Micro Machining Technologies

This chart illustrates the anticipated growth in the adoption of automation and AI technologies in the micro machining sector, along with the corresponding improvements in precision engineering innovations from 2023 to 2028.

Related Posts

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing