Exploring the Benefits of Home Plastic Injection Molding: A Deep Dive into Efficiency and Innovation

Home plastic injection molding is revolutionizing the way individuals approach manufacturing and prototyping at home. With advancements in technology, this once-industrial process has become accessible to hobbyists and small entrepreneurs, enabling them to create high-quality plastic parts with remarkable efficiency.

Dr. Emily Chen, a leading expert in advanced manufacturing techniques, noted, “The shift towards home plastic injection molding is not just about convenience; it's about empowering individuals to transform their ideas into reality with unprecedented precision and speed.”

In this deep dive, we will explore the myriad benefits that home plastic injection molding offers, focusing on the innovations that are transforming personal workshops into miniature manufacturing hubs. The ability to produce customized parts on-demand helps reduce material waste and lowers production costs, making it an attractive option for small-scale projects. By harnessing the power of home plastic injection molding, creators can iterate designs rapidly, fostering a culture of innovation and creativity like never before.

As we examine the top five advantages of embracing home plastic injection molding, we will uncover how this technology is not only enhancing efficiency but also reshaping the landscape of DIY manufacturing. Join us on this journey as we delve into the exciting possibilities that await those who dare to explore this innovative approach.

Understanding Home Plastic Injection Molding: Basics and Setup Requirements

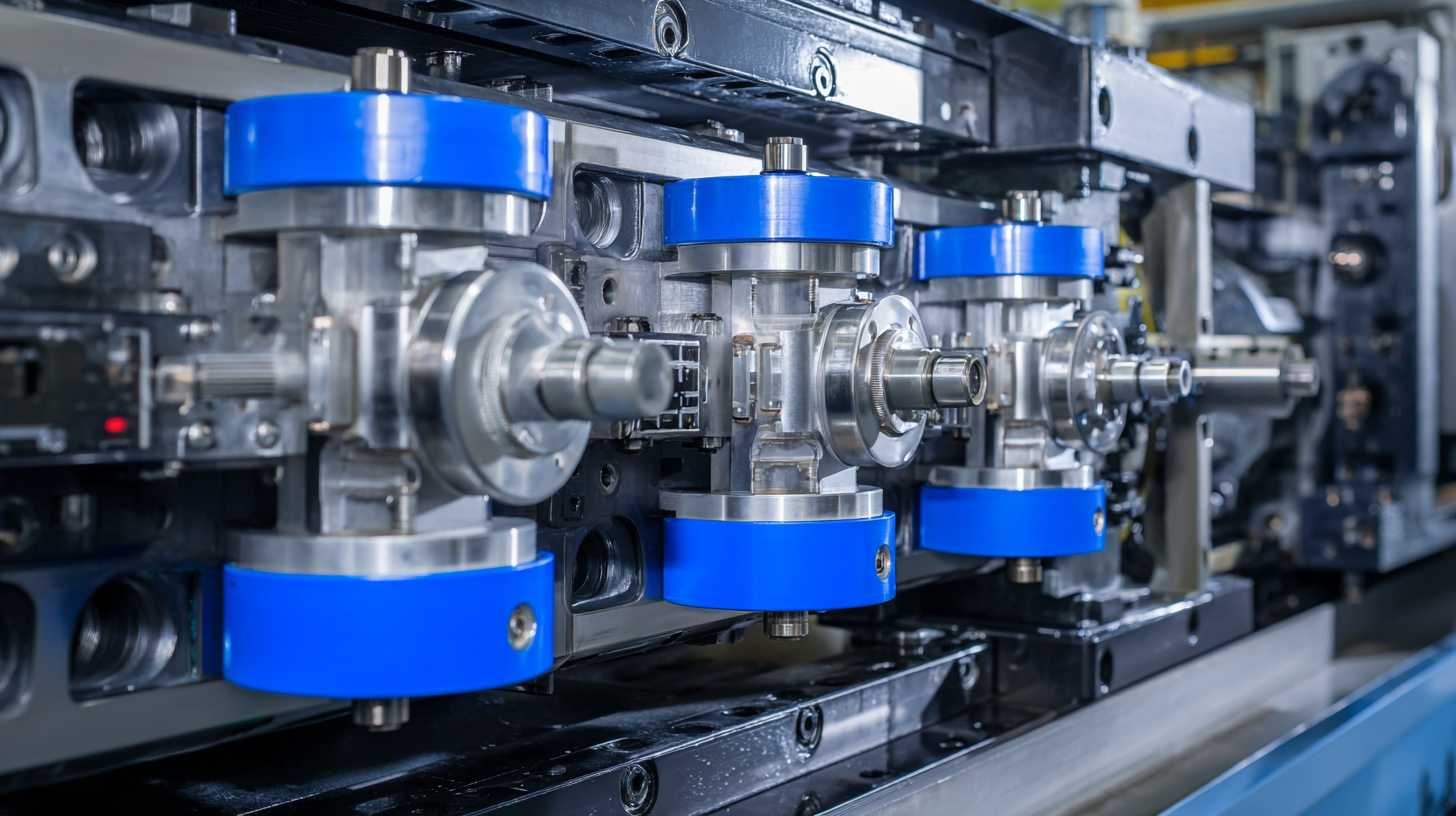

Home plastic injection molding is an innovative and efficient method that allows individuals to produce high-quality plastic parts from the comfort of their own homes. Understanding the basics and setup requirements is crucial for those interested in this exciting technology. A desktop injection molding machine, for instance, serves as a faster and often more adaptable alternative to traditional 3D printing, producing ready-to-use items in a fraction of the time. The market for injection molding machines is projected to grow significantly, with estimates suggesting a leap from USD 17.56 billion in 2025 to USD 25.78 billion by 2033, underscoring the increasing demand for accessible plastic manufacturing.

Setting up a home injection molding space involves several key considerations. First, selecting the right molding machine is vital; options range from compact desktop models to larger machines suited for more advanced users. Additionally, one should be aware of the essential materials and maintenance requirements to ensure optimal performance.

**Tips:** When starting out, focus on selecting a machine that fits your production goals. Consider starting with simpler designs to familiarize yourself with the process before progressing to more complex projects. Get acquainted with safety protocols to protect yourself and maintain a clean workspace, which will enhance your efficiency in the long run.

Exploring the Benefits of Home Plastic Injection Molding

This chart illustrates the key benefits of home plastic injection molding, highlighting aspects such as cost efficiency and customization opportunities. The data represents the relative importance of each benefit, showcasing the potential for innovation and efficiency in home manufacturing setups.

Choosing the Right Equipment and Materials for Home Injection Molding Projects

In home plastic injection molding, selecting the right equipment and materials is crucial for achieving optimal results. High-performance thermoplastics such as PEI (Polyetherimide) are increasingly favored due to their excellent thermal stability and mechanical strength. According to industry reports, the demand for precision injection molding has surged, with manufacturers requiring materials that can withstand higher frequencies and smaller component designs in electronic applications. As the market trends evolve towards miniaturization, the choice of materials will significantly impact the final product's durability and functionality.

When setting up a home injection molding system, investing in quality equipment is a key factor in ensuring success. High-quality injection molding machines can provide the necessary precision and consistency, leading to better performance of the final products. Additionally, understanding the specific requirements of your projects will guide you in choosing the right machine, such as those designed for high-speed processing or lower-volume custom jobs.

Tips: Always evaluate the mechanical properties of your chosen material to match your project's needs. Consider starting with small-scale projects to familiarize yourself with the equipment and material behaviors before tackling larger, more complex designs. This approach not only boosts your efficiency but also paves the way for innovative solutions in your home manufacturing endeavors.

Step-by-Step Guide to Creating Your First Plastic Injection Mold

Creating your first plastic injection mold can be a rewarding venture that enhances your understanding of the manufacturing process and opens avenues for innovation. This step-by-step guide will walk you through the essentials of home plastic injection molding, giving emphasis to efficiency and cost-effectiveness. According to a report by the Plastic Industry Association, the U.S. injection molding market is projected to grow at a rate of 3.9% annually, highlighting the increasing demand for efficient manufacturing techniques.

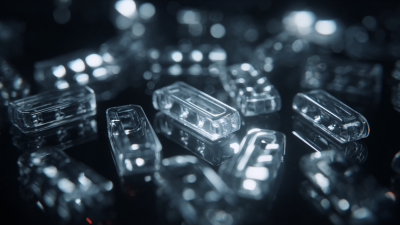

Begin by sourcing the right materials and tools, which typically include a home injection molding machine, thermoplastic pellets, and mold-making components. It’s crucial to choose the right type of plastic, as different materials offer unique properties and benefits. For instance, ABS is favored for its durability, while PLA is preferred for its biodegradable qualities. Once you’ve selected your materials, design your mold using CAD software, ensuring precision and alignment for optimal results.

After constructing your mold, the actual injection process involves heating the plastic until it becomes pliable and injecting it into the mold cavity. The cooling phase usually takes a matter of minutes and is crucial for achieving the desired finish. Industry experts note that this approach can reduce production time by as much as 60% compared to traditional manufacturing methods. By demystifying the process of home plastic injection molding, you can tap into a world of innovation that not only fulfills personal projects but also scales into potential business opportunities.

Maximizing Efficiency: Tips for Optimizing the Injection Molding Process

Maximizing efficiency in the injection molding process is crucial for any manufacturer aiming to stay competitive in the ever-evolving plastic industry. One of the latest advancements involves the design of optimized injection molding cells, which can significantly improve material flow while reducing the overall footprint and energy consumption of production facilities. Research shows that implementing these optimized cells can result in up to a 30% reduction in energy usage, which is not only beneficial for cost savings but also aligns with sustainability initiatives being prioritized in today's market.

To further enhance the injection molding process, businesses can leverage multi-cavity molding techniques. This approach allows for the simultaneous production of multiple parts within a single cycle, boosting output and efficiency in mass production scenarios. Reports indicate that manufacturers employing multi-cavity molds have seen productivity increases of 50% or more, underscoring the technique’s importance in maximizing resources.

Here are some tips for optimizing the injection molding process: Firstly, invest in automation to streamline operations and minimize labor challenges. Automation can help reduce cycle times and improve consistency in product quality. Secondly, conduct regular maintenance on molding machines to ensure they operate at peak efficiency, thus extending their lifespan and reducing downtime. By implementing these strategies, manufacturers can significantly enhance their injection molding efficiency and meet rising demand in a sustainable manner.

Exploring the Benefits of Home Plastic Injection Molding: A Deep Dive into Efficiency and Innovation

| Aspect | Description | Benefits |

|---|---|---|

| Cost Effectiveness | DIY injection molding can significantly reduce costs compared to outsourcing production. | Lower production costs and higher profit margins. |

| Material Versatility | Home injection molding allows for the use of various plastic materials. | Ability to choose materials based on specific product needs. |

| Rapid Prototyping | Quickly produce prototypes to test product designs. | Faster product development cycles. |

| Precision and Consistency | Injection molding offers high precision in part dimensions. | Consistent quality across production runs. |

| Customization | Ability to customize designs and production runs easily. | Greater flexibility in product design. |

Innovative Applications: Exploring Creative Uses for Home Injection Molded Items

Home plastic injection molding is revolutionizing how individuals create and customize items around their homes. With the injection molding market projected to grow from USD 365.22 billion in 2024 to USD 580.44 billion by 2033, at a compound annual growth rate (CAGR) of 4.74%, it is clear that this technology is more accessible than ever. This growth is driven by the increasing demand for personalized products that cater to specific needs, offering a unique avenue for creativity and innovation in everyday objects.

Innovative applications of home injection molded items are limitless. From bespoke kitchen utensils to custom toy designs, homeowners can now produce high-quality items tailored to their lifestyle. This technology not only enhances efficiency, enabling rapid prototyping and iterations, but also fosters sustainability by allowing users to create items using recycled materials. The combination of efficiency and creativity positions home plastic injection molding as a transformative tool for DIY enthusiasts, designers, and eco-conscious consumers alike, unlocking new potentials in personal and commercial applications.

Related Posts

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations

-

Understanding the Future of Plastic Components in Sustainable Manufacturing Processes

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing

-

Revolutionizing Manufacturing: The Impact of Super Finishing Process on Product Quality and Efficiency