What is Injection Molded Parts and How They are Made

Injection molded parts are integral components in the modern manufacturing landscape, playing a crucial role in various industries ranging from automotive to consumer goods. This process involves the creation of parts by injecting molten material into a pre-designed mold, allowing for the rapid and efficient production of complex shapes and sizes. The versatility of injection molded parts makes them a preferred choice for engineers and designers looking to achieve high precision and consistency in their products.

Understanding how injection molded parts are made involves delving into the two primary phases: mold design and the injection molding process itself. A well-conceived mold is essential, as it not only dictates the final shape of the parts but also influences the overall production efficiency. The injection molding process, characterized by its speed and scalability, ensures that large quantities of parts can be produced with minimal waste, thus enhancing cost-effectiveness.

In this discussion, we will explore the intricacies of injection molded parts, examining the materials commonly used, the advantages of this manufacturing method, and the impact it has on various industries. By shedding light on this vital technique, we aim to provide a deeper understanding of the fabrication of injection molded parts and their significance in today’s fast-paced market.

What Are Injection Molded Parts?

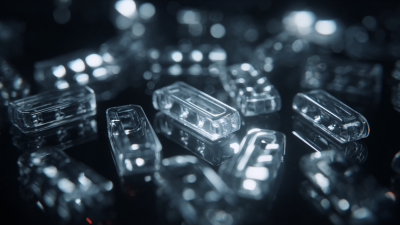

Injection molded parts are items produced through a manufacturing process that involves injecting molten material into a mold. This method is predominantly used for creating parts from thermoplastics and thermosetting polymers, which are heated until they become malleable and can be shaped. Once the material is injected into the mold, it is allowed to cool and solidify, resulting in a final product that can be removed from the mold cavity. The precision and efficiency of this process make it an essential technique in various industries, including automotive, consumer goods, and electronics.

The versatility of injection molded parts is one of their most significant advantages. They can be made in a wide range of shapes, sizes, and complexities, allowing for intricate designs that are often difficult to achieve with other manufacturing methods. Additionally, the injection molding process can accommodate high-volume production runs, leading to economies of scale. This makes it possible to produce identical parts rapidly and cost-effectively, which is crucial for applications such as automotive components, medical devices, and household products. The ability to incorporate different materials and color options further enhances the appeal of injection molded parts across diverse sectors.

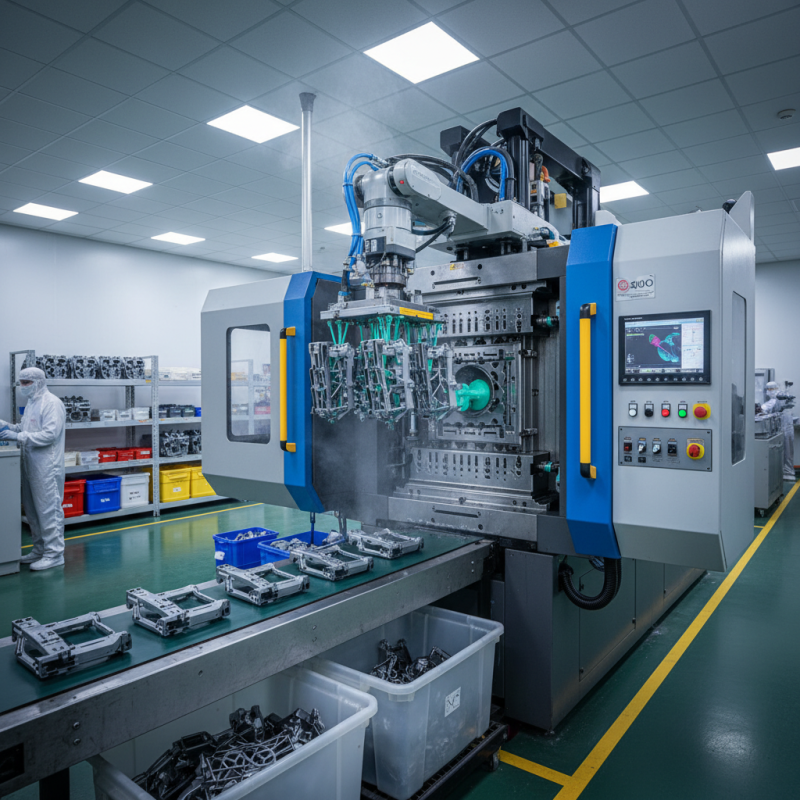

Key Components of Injection Molding Machines

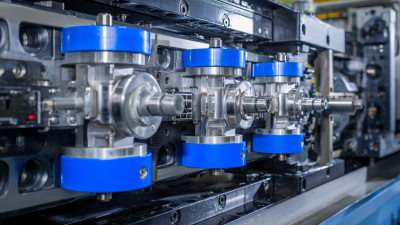

Injection molding is a widely used manufacturing process for producing plastic parts, and understanding the key components of injection molding machines is essential for grasping how these parts are made. The injection molding machine primarily consists of two main sections: the injection unit and the clamping unit. The injection unit is responsible for melting plastic pellets and injecting the molten plastic into a closed mold under high pressure. This unit typically includes a hopper for loading raw materials, a barrel for melting the plastic, and a screw mechanism that helps in the mixing and injecting process.

The clamping unit, on the other hand, plays a critical role in ensuring that the mold remains closed during the injection phase and opens to eject the finished part. This unit consists of a movable platen and a fixed platen, typically connected by tie bars. The clamping force must be strong enough to withstand the pressure during injection, preventing any leakage of the molten material. Additionally, the machine may include controls for temperature regulation, cycle timing, and pressure settings, which are vital for achieving high-quality molded parts. Understanding these components helps in appreciating the intricacies involved in the injection molding process and its applications across various industries.

The Injection Molding Process Explained Step by Step

The injection molding process is a crucial manufacturing technique for creating parts from thermoplastic and thermosetting plastic materials. This method involves several steps: first, raw plastic material is heated until it reaches a molten state. In 2021, the global injection molding market was valued at approximately $286.47 billion, indicating its significant role in various industries, particularly in automotive, consumer goods, and electronics. The molten plastic is then injected into a precisely designed mold under high pressure, allowing it to fill the cavity completely.

After the material fills the mold, it is cooled, solidifying into the desired shape. The cooling process can vary in time depending on the thickness of the parts, with thicker sections generally requiring longer cooling times. Industry reports suggest that nearly 40% of the total cycle time in injection molding is dedicated to cooling. Once cooled, the mold is opened, and the finished part is ejected. The efficiency of this process, along with the ability to produce complex geometries and high-volume output, makes injection molding a preferred choice for manufacturers, with 3D modeling software aiding in the design and prototyping phases.

Each cycle of this process is typically completed within 15-60 seconds, showcasing its rapid production capability.

Materials Used in Injection Molded Parts

Injection molded parts are manufactured using a wide range of materials, each chosen for specific properties that align with the intended application. The most common materials include thermoplastics, thermosetting plastics, and metals. Thermoplastics, such as polypropylene and polycarbonate, dominate the market due to their excellent moldability, recyclability, and cost-effectiveness. According to a report by Mordor Intelligence, the thermoplastics segment is expected to witness substantial growth, with the market projected to reach approximately USD 380 billion by 2026.

In addition to thermoplastics, engineers may choose thermosetting plastics, which are known for their heat resistance and structural integrity. Materials like epoxy and phenolic resin fall into this category and are often utilized in high-temperature applications. The choice of material significantly influences not only the mechanical and thermal properties of the final product but also its aesthetic and functional characteristics. Metal injection molding, using materials like stainless steel and titanium alloys, is also gaining traction, particularly in manufacturing complex components with high precision. The global metal injection molding market is expected to grow at a CAGR of 8.5%, highlighting the increasing reliance on advanced materials in the injection molding sector.

Applications and Benefits of Injection Molded Parts

Injection molded parts are widely used across various industries due to their versatility and efficiency. One of the primary applications of injection molded components is in the automotive sector, where they are used to create interior and exterior parts like dashboards, trims, and housings. The precision and ability to produce complex shapes allow for lightweight designs that enhance fuel efficiency while maintaining durability. Additionally, consumer electronics utilize injection molded parts to manufacture enclosures, connectors, and buttons, providing the aesthetic appeal and robust functionality required in modern devices.

The benefits of injection molded parts extend beyond just their applications. They offer high production efficiency, enabling manufacturers to produce large volumes with minimal waste. The process allows for the use of various materials, including plastics and metals, which can be tailored to meet specific performance requirements. Furthermore, injection molding enables high precision and repeatability, essential for maintaining quality in mass production. The ability to use multiple materials in a single mold contributes to the creation of complex assemblies, reducing the need for additional assembly steps. As industries continue to evolve, the demand for injection molded parts remains strong, driven by their adaptability and cost-effectiveness.

Related Posts

-

Exploring the Future of Plastic Components: Innovations and Sustainability in Modern Manufacturing

-

Exploring the Benefits of Home Plastic Injection Molding: A Deep Dive into Efficiency and Innovation

-

2025 Top Machining Tools: Revolutionizing Precision and Efficiency in Manufacturing

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

Why Super Finishing Is Essential for Achieving a Surface Roughness of Up to Ra 0.1µm