Top Benefits of Micro Machining for Precision Engineering Applications

Micro machining technology has revolutionized the precision engineering landscape, enabling the fabrication of intricate components with incredible accuracy. As industries demand smaller, more complex parts, micro machining has emerged as a critical solution. According to a recent report by MarketsandMarkets, the global micro machining market is projected to reach USD 3.61 billion by 2026, growing at a CAGR of 7.5% from 2021 to 2026. This growth is driven by advancements in manufacturing technologies and the increasing need for high-precision components across various sectors such as aerospace, medical devices, and electronics.

Experts in the field, such as Dr. Emily Thompson, a leading figure in micro machining research, highlights the significance of this technology by stating, "Micro machining not only enhances manufacturing precision but also improves production efficiency, allowing for higher-quality output without compromising on time." This statement underscores the pivotal role that micro machining plays in meeting the stringent demands of the modern manufacturing environment. As applications for micro machined parts continue to expand, the benefits of this technology—ranging from reduced material waste to enhanced functionality—position it as an indispensable tool in the ever-evolving world of precision engineering.

Benefits of Micro Machining in Precision Engineering

Micro machining has emerged as a game-changer in precision engineering, offering a range of benefits that are critical for industries demanding high accuracy and miniaturization. One of the primary advantages is the ability to create intricate designs with exceptional precision. This technology enables engineers to produce components that are smaller and more complex than ever, facilitating innovations in sectors such as aerospace, medical devices, and electronics. The high degree of accuracy achieved through micro machining ensures that even the tiniest features maintain their integrity, which is essential for the overall functionality of precision-engineered products.

Another significant benefit of micro machining is its efficiency in material usage. Traditional machining methods often result in substantial waste, but micro machining techniques are designed to minimize material loss. By utilizing advanced cutting tools and precise control systems, manufacturers can achieve tighter tolerances and reduce scrap rates. This efficiency not only lowers production costs but also supports sustainable manufacturing practices, making it an attractive option for companies looking to enhance their environmental responsibility.

Overall, the impact of micro machining on precision engineering applications cannot be overstated, as it continues to drive advancements and improvements across a variety of fields.

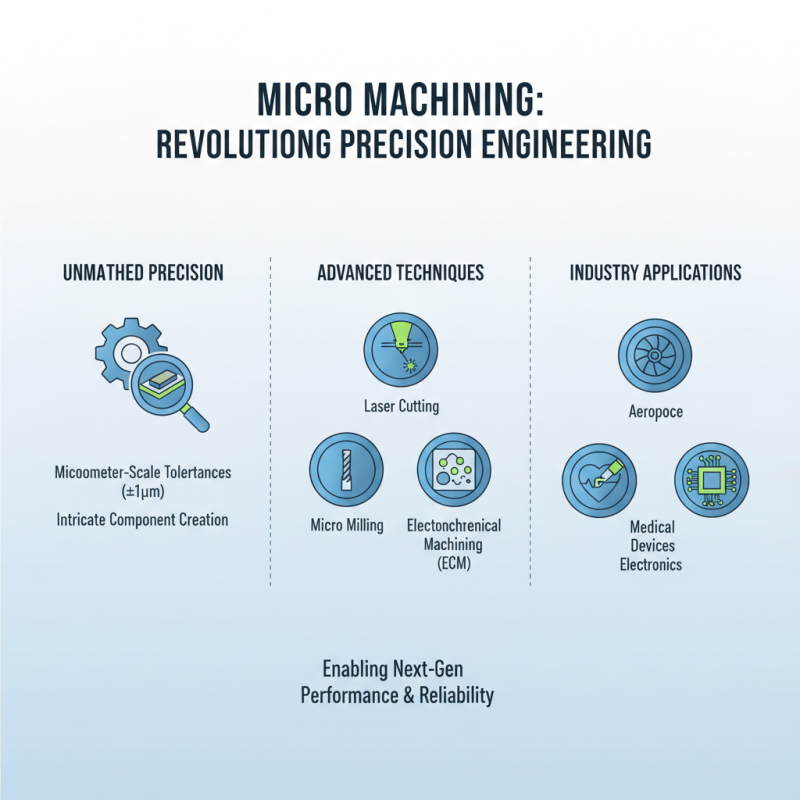

High Precision Tolerance Achieved with Micro Machining Techniques

Micro machining has revolutionized precision engineering by allowing manufacturers to achieve high precision tolerances that were previously unattainable with conventional machining methods. By utilizing advanced techniques such as laser cutting, micro milling, and electrochemical machining, engineers can create intricate components with tolerances reaching the micrometer scale. This level of precision is essential in industries such as aerospace, medical devices, and electronics, where even the smallest deviation can lead to significant performance issues.

One of the key advantages of micro machining is its ability to fabricate complex geometries and delicate features. These techniques enable the production of components with fine details, such as miniature gears, intricate connectors, and custom implants, while maintaining structural integrity. Additionally, micro machining generates minimal waste material due to its high efficiency and precision, which not only contributes to cost-effectiveness but also supports sustainability efforts in manufacturing. As industries continue to demand higher precision and more complex designs, micro machining stands out as a vital technology for meeting these evolving needs.

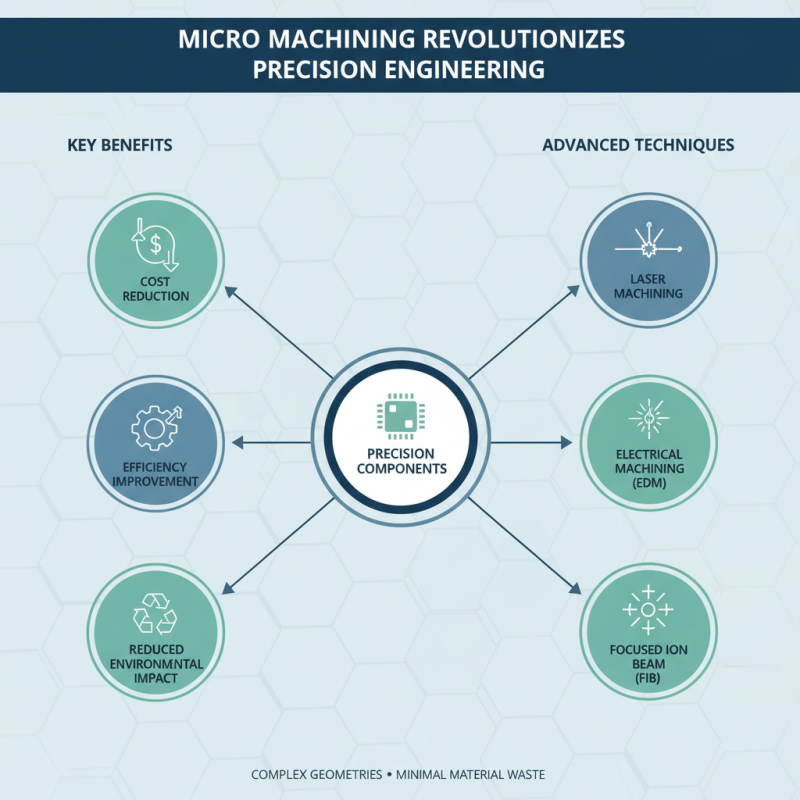

Cost Reduction and Efficiency Improvements in Manufacturing Processes

Micro machining provides significant cost reduction and efficiency improvements for precision engineering applications, revolutionizing traditional manufacturing processes. By utilizing advanced techniques such as laser, electrical discharge machining, and focused ion beam technologies, manufacturers can achieve complex geometries that were previously infeasible. This capability allows for the production of intricate components with minimal material waste, leading to lower raw material costs and a reduced environmental impact.

Furthermore, micro machining enhances production efficiency by enabling faster cycle times and higher levels of automation. The precision and repeatability of micro machining processes minimize the need for extensive manual intervention, thus streamlining operations and reducing labor costs. As a result, manufacturers can meet increasing demand for high-precision components while maintaining tight deadlines. This operational agility not only fosters competitive advantage but also aligns with the growing need for sustainable manufacturing practices.

Applications of Micro Machining in Aerospace and Medical Industries

Micro machining has emerged as a crucial technology in the aerospace and medical industries, offering unprecedented precision and efficiency in manufacturing critical components. According to a report by MarketsandMarkets, the global micro machining market is projected to grow significantly, with the aerospace sector accounting for a substantial share due to its need for lightweight and complex geometries. Precision-engineered parts, such as turbine blades and fuel nozzles, benefit from micro machining processes that allow for intricate designs while adhering to strict weight and performance standards.

In the medical field, micro machining plays a vital role in the production of advanced medical devices and diagnostics tools. For example, the micro fabrication of surgical instruments, implants, and microfluidic devices has become increasingly important as the demand for minimally invasive procedures rises. A report by Frost & Sullivan highlights that the medical micro machining market is expected to see a compound annual growth rate (CAGR) of over 10% in the coming years. This growth can be attributed to the precision and accuracy that micro machining techniques provide, ensuring the reliability and effectiveness of medical solutions in various applications, from implants to diagnostic equipment.

As both industries continue to evolve, the integration of micro machining processes will be essential in driving innovation and enhancing performance. The combination of high precision, reduced material waste, and customizable designs positions micro machining as a pivotal technology for meeting the demanding challenges of aerospace and medical applications in the future.

Top Benefits of Micro Machining for Precision Engineering Applications

Innovative Materials Utilized in Micro Machining for Enhanced Performance

Micro machining has revolutionized precision engineering by enabling the production of intricate components on a microscale. The innovation in materials used in this process significantly enhances overall performance, allowing for greater durability, reduced weight, and improved functionality. Advanced materials such as titanium alloys, ceramics, and composite materials are now commonly utilized in micro machining applications. These materials offer exceptional hardness and resistance to wear, making them ideal for high-performance components found in aerospace, medical devices, and electronics.

Furthermore, the incorporation of materials like polyimides and carbon nanofibers in micro machining provides opportunities for unprecedented mechanical properties. Polyimides, known for their high thermal stability and chemical resistance, are increasingly being used in micro machined components that must withstand extreme conditions. Similarly, carbon nanofibers contribute to the lightweight and strength characteristics needed for advanced applications. The use of these innovative materials not only enhances the longevity and reliability of machined parts but also allows for the design of more complex geometries that were previously unattainable. This synergy between cutting-edge materials and micro machining techniques continues to drive advancements in precision engineering, pushing the boundaries of what is possible in various industries.

Top Benefits of Micro Machining for Precision Engineering Applications - Innovative Materials Utilized in Micro Machining for Enhanced Performance

| Benefit | Description | Innovative Material | Performance Enhancement |

|---|---|---|---|

| Higher Precision | Micro machining allows for incredibly precise features and tolerances, making it perfect for small components. | Titanium Alloys | Increased strength-to-weight ratio, ideal for aerospace applications. |

| Reduced Waste | Using less material means lower waste, which is beneficial for cost and sustainability. | Aluminum Alloys | Provides excellent machinability while minimizing waste. |

| Complex Geometries | Micro machining can create intricate designs that are difficult or impossible with traditional methods. | Ceramic Materials | High hardness and thermal resistance, suitable for medical and electronic devices. |

| Shorter Lead Times | Advanced technologies enable quicker manufacturing processes, reducing overall delivery times. | Stainless Steel | Durability and corrosion resistance, speeding up development of prototypes. |

| Improved Functionality | Components can be optimized for their specific roles within larger systems. | Polymer Composites | Lightweight and customizable properties improve part functionality. |

Related Posts

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

Understanding the Future of Plastic Components in Sustainable Manufacturing Processes

-

What is Micro Machining? A Comprehensive Guide to Its Techniques and Applications

-

Top Benefits of Super Finishing Process for Precision Engineering Applications

-

Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes