What is Micro Machining? A Comprehensive Guide to Its Techniques and Applications

Micro machining is a cutting-edge manufacturing technology that has gained significant traction across various industries due to its ability to create intricate and precise components at the micro scale. According to a report by Markets and Markets, the global micro machining market is expected to reach USD 2.89 billion by 2025, growing at a CAGR of 7.5% from 2020. This growth is driven by the increasing demand for high-precision components in sectors such as electronics, aerospace, and medical devices.

Micro machining is a cutting-edge manufacturing technology that has gained significant traction across various industries due to its ability to create intricate and precise components at the micro scale. According to a report by Markets and Markets, the global micro machining market is expected to reach USD 2.89 billion by 2025, growing at a CAGR of 7.5% from 2020. This growth is driven by the increasing demand for high-precision components in sectors such as electronics, aerospace, and medical devices.

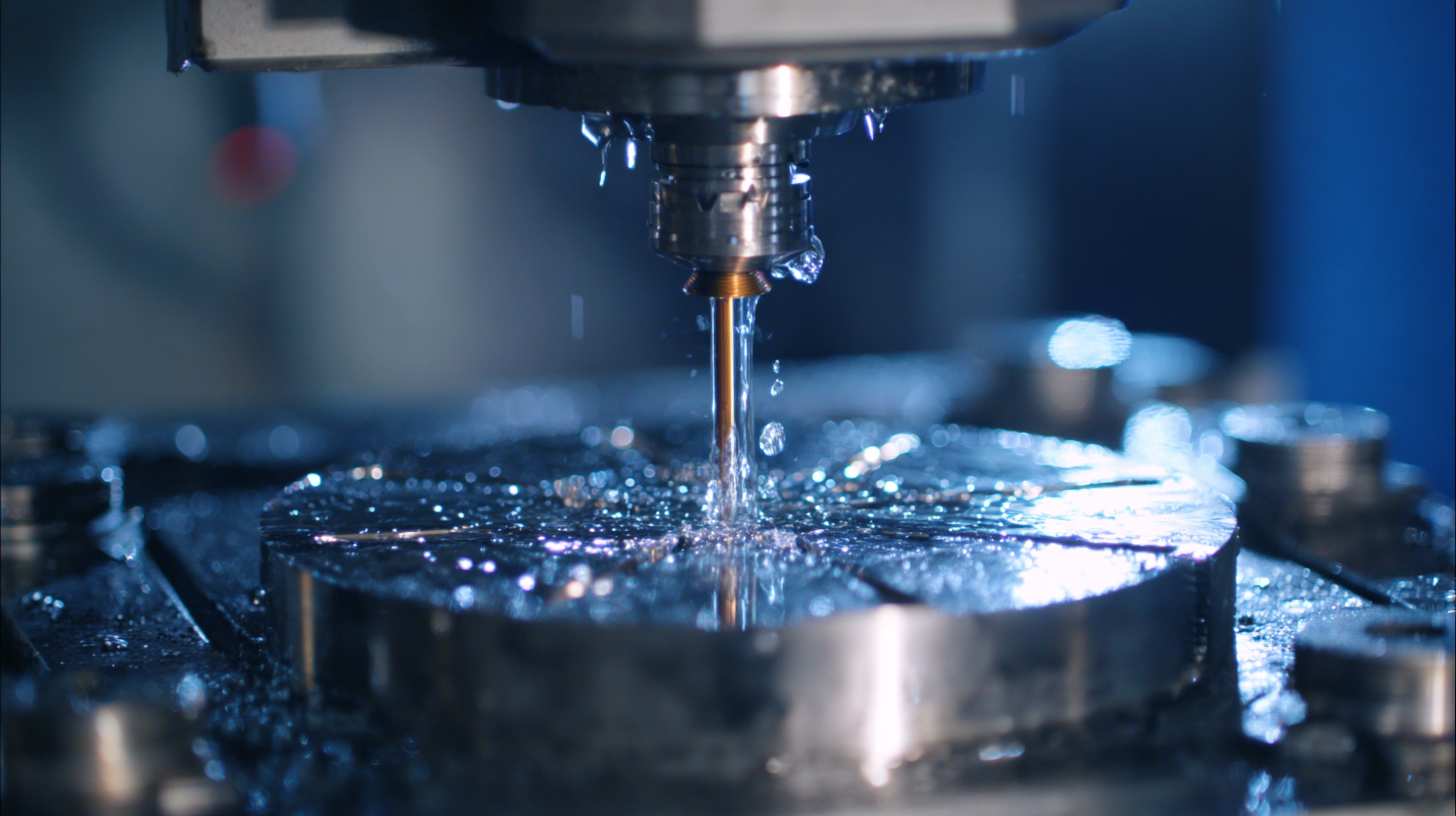

The versatility of micro machining techniques, including laser micro machining, electrical discharge machining (EDM), and micro milling, allows manufacturers to produce complex geometries with exceptional accuracy. As industries continue to push the boundaries of miniaturization and performance, micro machining emerges as a vital process for innovation. By harnessing advanced technologies, companies are not only improving the functionality of their products but also achieving higher efficiencies in production.

This comprehensive guide will delve into the various techniques of micro machining, highlighting their respective applications and the implications for future advancements. As we explore the world of micro machining, we'll uncover how these sophisticated processes are revolutionizing manufacturing and setting new benchmarks in precision engineering.

Overview of Micro Machining: Definition and Importance

Micro machining is a highly specialized manufacturing technique that focuses on creating intricate parts and features on a micro-scale, typically in the range of micrometers to millimeters. This precision is vital in various industries, including electronics, aerospace, and medical devices. According to a report by Research and Markets, the global micro machining market was valued at over $400 million in 2020 and is expected to grow significantly, driven by advances in manufacturing technologies and the increasing demand for miniaturized components.

The importance of micro machining lies in its ability to produce parts that are not only precise but also efficient. For instance, in the medical industry, micro machining techniques enable the production of complex structures necessary for surgical instruments and implants, resulting in improved patient outcomes. As per a study published by the International Journal of Advanced Manufacturing Technology, micro machining processes can achieve tolerances of up to ± 1 micron, showcasing the method's capability to meet the stringent requirements of modern applications. This fusion of innovation and precision establishes micro machining as an essential approach in contemporary manufacturing processes.

Key Techniques in Micro Machining: Tools and Processes Explored

Micro machining is revolutionizing manufacturing with its precision and versatility, particularly in applications like drilling, cutting, and engraving. Recent market analyses show that the laser micromachining tools market is witnessing significant growth, driven by increasing demand for intricate designs in various industries, including electronics and medical devices. According to industry reports, the global laser micromachining market was valued at approximately $150 million in 2020 and is projected to reach around $250 million by 2025, reflecting a compound annual growth rate (CAGR) of approximately 10%.

Key techniques in micro machining include laser-based processes such as cutting, scribing, and engraving. These techniques utilize focused laser beams to achieve high precision and fine detail, making them ideal for applications requiring minimal material removal or intricate designs. The COVID-19 pandemic has further accelerated demand in sectors like pharmaceuticals and medical equipment, where micro machining is critical for the production of small, complex parts. As industries continue to evolve and embrace advanced manufacturing technologies, the micro machining market is expected to thrive, presenting opportunities for innovation and expansion.

Applications of Micro Machining in Various Industries: A Breakdown

Micro machining has emerged as a vital technique across various industries, leading to innovations that enhance precision and efficiency. The global machining centers market, valued at $29.17 billion in 2018, is projected to reach $60.13 billion by 2032, exhibiting a compound annual growth rate (CAGR) of 4.9%. This growth reflects the increasing demand for precision components in sectors such as aerospace, automotive, and electronics. Specifically, applications like electrohydrodynamic (EHD) printing are pushing the boundaries of high-resolution patterning in flexible electronics, showcasing how micro machining can advance industrial capabilities.

In addition, the CNC machine market is expected to expand at a CAGR of 5.5%, demonstrating the industry's shift towards smarter manufacturing solutions. The integration of artificial intelligence (AI) into next-generation CNC machining is revolutionizing precision manufacturing, enabling more accurate and efficient production processes. The high precision mechanical machine components market is also on the rise, anticipated to reach USD 3.9 billion with a CAGR of 4.4% by 2035, indicating robust growth driven by the ongoing demand for high-quality, precise manufacturing solutions in multiple sectors.

Challenges and Solutions in Micro Machining Processes

Micro machining is a sophisticated manufacturing process that poses unique challenges due to the intricate nature of components being produced. According to a report by MarketsandMarkets, the global micro machining market is expected to reach $3.45 billion by 2025, indicating a significant demand for these advanced technologies. However, the precision required in micro machining often leads to various obstacles, such as tool wear, thermal effects, and accessibility issues in machining operations. These factors can compromise the quality and accuracy of the final product, emphasizing the need for innovative solutions.

To address these challenges, industries are increasingly adopting advanced technologies like laser micro machining and electrical discharge machining (EDM). For instance, the use of laser beams in micro machining has been proven to reduce thermal distortion and improve precision, with advancements leading to tolerances of up to ±5 micrometers. Additionally, integrating real-time monitoring systems can enhance process control, ensuring optimal performance and reducing downtime. Embracing these techniques not only mitigates the inherent challenges of micro machining but also drives the industry towards more efficient and precise manufacturing solutions.

Micro Machining Techniques and Applications

Future Trends in Micro Machining: Innovations and Technologies

The landscape of micro machining is rapidly evolving, driven by innovations and advancements across various technologies. One notable trend is the increasing application of MEMS (Micro-Electro-Mechanical Systems) in micro machining processes. MEMS not only enhance the precision of machining operations but also enable greater miniaturization. The diverse methodologies for driving MEMS mirrors showcase how technology is advancing, emphasizing principles of functionality and efficiency. This shift towards smart, miniaturized components reflects a broader movement within industries aiming to integrate more intelligent systems.

Moreover, the laser processing equipment sector exemplifies a robust growth trajectory, particularly within markets like China, which is positioned as the largest industrial laser market. Anticipated growth in market size, alongside a substantial influx of laser processing devices, underscores the sector's responsiveness to policy support and technological advancements. As sectors embrace these innovations, the integration of sophisticated optical components further enhances capabilities in micro machining. The trend of marrying high-precision laser techniques with intelligent system designs is likely to define the future of micro machining, characterizing a new era of efficiency and innovation.

What is Micro Machining? A Comprehensive Guide to Its Techniques and Applications

| Technique | Description | Applications | Future Trends |

|---|---|---|---|

| Laser Micromachining | Utilizes focused laser beams to remove material with high precision. | Micro-components, electronics, medical devices. | Growth in automation and integration with AI technologies. |

| EDM (Electrical Discharge Machining) | Involves erosion of material by electrical discharge between electrodes. | Molds, die manufacturing, complex geometries. | Advancements in electrode materials and efficiency improvements. |

| Micro Milling | Removal of material using rotary tools with very small diameters. | Precision parts, automotive components. | Increased use of high-speed machining techniques. |

| Chemical Machining | Involves the use of chemical etchants to remove layers of material. | Aerospace, semiconductor fabrication, intricate designs. | Development of eco-friendly etching processes. |

| Focused Ion Beam (FIB) Machining | Uses a focused beam of ions to mill materials at the nanoscale. | Nanotechnology, precision research applications. | Miniaturization of components and improvements in imaging technologies. |

Related Posts

-

10 Essential Tips for Selecting Titanium Alloy: Insights from Industry Experts and Market Trends

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

How to Achieve Superior Results with Super Finishing Techniques

-

Exploring the Future of Plastic Parts: Innovations Shaping Tomorrow's Manufacturing

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

Understanding the Plastic Injection Moulding Process: A Comprehensive Guide for Beginners