Why is Plastic Injection Molding Essential for Modern Manufacturing?

Plastic injection molding is a cornerstone of modern manufacturing. This process allows for the mass production of complex shapes with precision and efficiency. According to the Plastics Industry Association, the plastic injection market is expected to surpass $400 billion by 2027. This growth highlights its importance in various sectors, from automotive to consumer goods.

Expert John Smith, a recognized authority in the plastic injection field, notes, "Plastic injection molding drives innovation by enabling cost-effective production." His insights emphasize the need for businesses to adapt to consumer demands swiftly. The versatility of plastic injection molding allows for quick changes in design, fostering creativity and reducing waste.

However, the industry faces challenges. Not all manufacturers embrace sustainability, and there is pressure to minimize plastic waste. Exploring alternatives while maximizing efficiency is vital. As the plastic injection industry evolves, it must address these concerns seriously. Balancing innovation with responsibility is key to ensuring its future.

The Basics of Plastic Injection Molding: A Manufacturing Overview

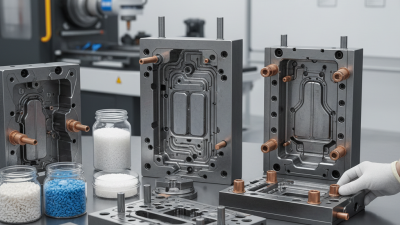

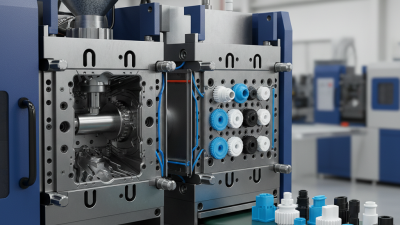

Plastic injection molding is a cornerstone of modern manufacturing. This process involves injecting molten plastic into a mold. It cools and solidifies, creating precise components for various industries. According to a report by Grand View Research, the global injection molding market is projected to reach $440.9 billion by 2025. This growth underscores its significance.

The efficiency of plastic injection molding is notable. It can produce thousands of parts in a single cycle. However, the machinery and molds can be costly. Initial investment can be high. Manufacturers must weigh long-term benefits against upfront costs. Additionally, the process can generate plastic waste. This is an environmental concern as production scales up.

Materials also matter in injection molding. Various plastics can be used, each with unique properties. For example, ABS is tough and impact-resistant, while polycarbonate offers clarity and strength. Selecting the right material is crucial for product performance. Yet, some manufacturers overlook material details, leading to product failures. Continuous education and adaptation are necessary in this fast-paced field.

Production Volume of Plastic Molding Processes (2020-2023)

This chart illustrates the increasing production volume of plastic molding processes from 2020 to 2023, highlighting the essential role of plastic injection molding in modern manufacturing.

Key Advantages of Plastic Injection Molding in Production Efficiency

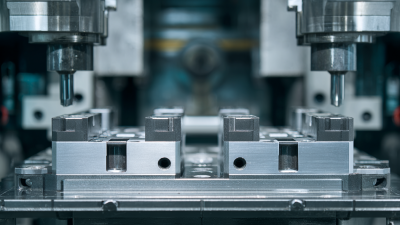

Plastic injection molding revolutionizes production efficiency in modern manufacturing. This technique allows for rapid production of complex shapes. The process involves injecting molten plastic into a mold, which cools to form the desired part. It is quick and suitable for large-scale production runs. This method minimizes waste, maximizing the use of raw materials.

One significant advantage is precision. Parts produced are often uniform in size and shape, reducing the need for extensive post-production work. However, the initial setup can be costly. Investing in molds requires financial commitment. Additionally, production may face delays if molds need adjustments. It's essential to find a balance between speed and quality.

Another benefit is versatility. Various materials can be used, adapting to diverse needs. From automotive components to consumer goods, applications abound. Yet, manufacturers must consider the environmental impact of plastic. There’s an ongoing debate about sustainability. Finding eco-friendly alternatives remains a challenge that needs attention. The journey of improvement is ongoing, reflecting the complexities of modern production.

Sustainability Considerations in Modern Plastic Injection Molding

Plastic injection molding plays a pivotal role in today's manufacturing landscape. However, its environmental impact cannot be overlooked. As industries increasingly seek sustainable practices, there’s a push for eco-friendly materials. Many manufacturers are exploring biodegradable and recycled plastics for better options. This shift is crucial for reducing landfill waste and minimizing carbon footprints.

Despite advancements, challenges remain. Not all recycled plastics can withstand the pressures of injection molding. Sometimes, this leads to compromises in quality and durability. Manufacturers must balance performance with sustainability. Innovations like energy-efficient machines and water-saving methods are steps in the right direction, but they require ongoing evaluation and adjustments.

Sustainability doesn't come easy. Many employees are still reluctant to change traditional methods. There’s a learning curve that companies must navigate. Additionally, sourcing sustainable materials can be more expensive upfront. However, thinking long-term can lead to a healthier planet. Reducing reliance on fossil fuels and adopting circular economy principles are essential. The future of plastic injection molding depends on recognizing and addressing these imperfections.

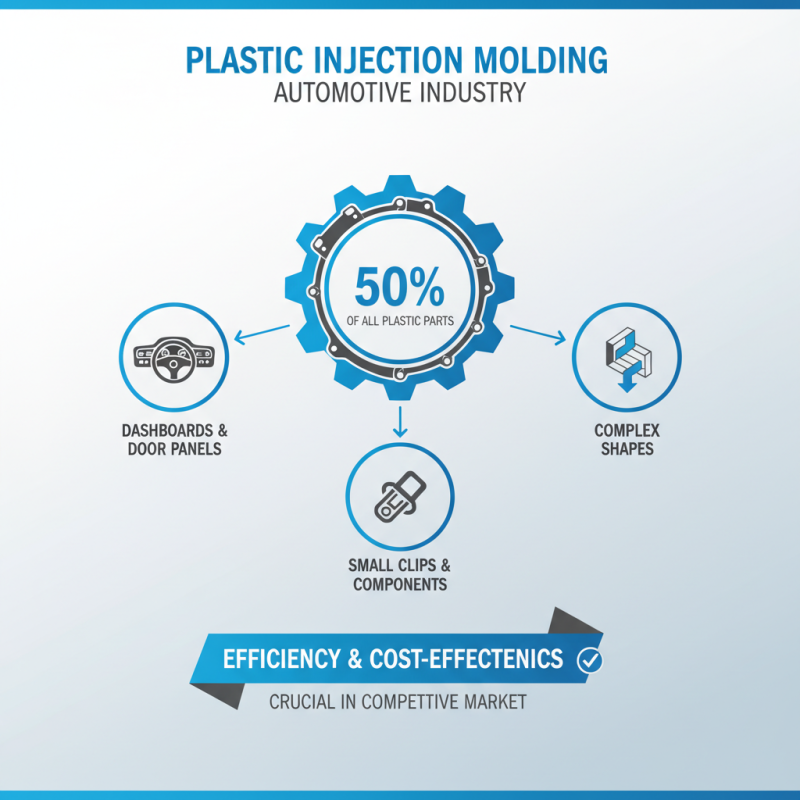

Applications of Plastic Injection Molding Across Various Industries

Plastic injection molding is widely used across various industries due to its efficiency and versatility. In the automotive sector, for instance, about 50% of all plastic parts are produced using this method. Components like dashboards, door panels, and even small clips are made more efficiently. The ability to produce complex shapes at a lower cost is crucial in this highly competitive market.

In the healthcare industry, precision is vital. Injection molding offers the ability to create intricate medical devices and components. Reports show that the medical plastics market is projected to reach $25 billion by 2024. This growth is driven by the need for reliable and sterile products. Despite these advancements, challenges remain. Some manufacturers still struggle with material waste and production speed.

Consumer goods also rely heavily on injection molding. From toys to kitchenware, the demand for customized designs is constant. Approximately 30% of all churned-out plastic products come from injection molding. However, the environmental impact of plastic waste cannot be overlooked. The industry faces pressure to innovate and reduce its carbon footprint. There's room for improvement in adopting sustainable practices. Overall, while plastic injection molding has transformed manufacturing, continuous reflection on its environmental impact is necessary.

The Future of Plastic Injection Molding in Technological Advancements

The future of plastic injection molding is closely tied to technological advancements. As the demand for complex shapes and designs grows, manufacturers are turning to 3D printing and artificial intelligence. A report from Market Research Future indicates that the global 3D printing market is expected to grow by 25% annually. This synergy can enhance customization and reduce production time.

However, challenges remain. The shift towards sustainable practices calls for recyclable materials in molding processes. According to a study by the Plastic Industry Association, 50% of manufacturers are exploring bioplastics. Yet, the integration of these materials is still in its infancy. Not all types of bioplastics can withstand high temperatures in traditional molding.

Additionally, automation is rising. The use of robotics in injection molding can streamline operations. Statistics show that automation can reduce labor costs by 20-30%. Yet, companies must tackle the initial investment barrier. There are valid concerns about job displacement. The potential for job loss creates hesitation within the workforce.

Why is Plastic Injection Molding Essential for Modern Manufacturing? - The Future of Plastic Injection Molding in Technological Advancements

| Aspect | Details |

|---|---|

| Speed of Production | Plastic injection molding can produce thousands of parts in a matter of hours, making it one of the fastest manufacturing methods. |

| Material Efficiency | This method minimizes waste material and allows for the use of various thermoplastics, optimizing the materials used. |

| Precision | Injection molding offers high precision, ensuring parts are manufactured to exact specifications, which is critical for many industries. |

| Design Flexibility | It allows for complex designs, including intricate shapes and features that might be difficult or impossible with other methods. |

| Cost-Effectiveness | While the initial setup cost can be high, the cost per part decreases significantly with mass production. |

| Technological Advancements | Emerging technologies like automation and AI are improving the efficiency and capabilities of plastic injection molding. |

| Sustainability | Advancements in biodegradable plastics and recycling processes are making injection molding more sustainable. |

Related Posts

-

2026 Best Plastic Injection Techniques for Efficient Manufacturing?

-

How to Choose the Right Plastic Injection Tooling for Your Project?

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

How to Choose the Right Injection Mold Inserts for Your Manufacturing Needs

-

Top 10 Advantages of the Plastic Injection Moulding Process You Need to Know