Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes

In the ever-evolving landscape of modern manufacturing, the plastic injection mold has emerged as a cornerstone technology, enabling the efficient production of complex and high-precision components across various industries. From automotive parts to consumer goods, the role of plastic injection molds is indispensable in achieving not only high-volume outputs but also consistent quality.

This article aims to delve into the intricacies of plastic injection molds, exploring their design, functionality, and the latest innovations that enhance their performance. By understanding the critical aspects of plastic injection mold technology, manufacturers can optimize their processes, reduce production costs, and improve product quality, ultimately gaining a competitive edge in the marketplace.

Join us as we uncover valuable tips and insights that will elevate your understanding and application of plastic injection molds in contemporary manufacturing.

The Importance of Plastic Injection Molds in Reducing Manufacturing Costs

Plastic injection molds have become essential in modern manufacturing, primarily due to their ability to significantly reduce production costs. According to a report by the Plastic Industry Association, for every dollar spent on manufacturing with injection molds, companies can save up to 30% compared to traditional manufacturing methods. This is largely attributed to the efficiency of the injection molding process, which allows for mass production of complex parts with minimal waste. As the demand for high-quality, low-cost products increases, leveraging plastic injection molds has become a strategic advantage for manufacturers.

Moreover, the quick turnaround time offered by plastic injection molding enhances the overall production cycle, leading to faster time-to-market. A study by Grand View Research indicates that the global injection molding market is projected to reach USD 345.5 billion by 2025, underscoring its importance in maintaining competitive pricing while meeting consumer demands.

**Tips:** When considering plastic injection molds, invest in high-quality materials and the latest technology to improve efficiency and durability. Additionally, regular maintenance of molds can prevent costly downtimes and prolong their lifespan, ultimately maximizing cost savings in the manufacturing process. Implementing these practices can lead to a significant reduction in operational costs while enhancing product quality.

Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes - The Importance of Plastic Injection Molds in Reducing Manufacturing Costs

| Dimension | Description | Impact on Manufacturing Costs |

|---|---|---|

| Material Efficiency | Plastic injection molds allow for precise material usage, minimizing waste. | Reduces raw material costs by up to 20%. |

| Production Speed | High-cycle times due to fast injection and cooling processes. | Increases output, lowering labor costs per unit. |

| Design Flexibility | Allows for complex shapes and reductions in assembly requirements. | Lowers assembly costs and enhances product appeal. |

| Tooling Costs | Initial costs can be high, but are amortized over mass production. | Long-term savings on production runs often outweigh initial investments. |

| Quality Control | Consistent molds ensure uniform quality across products. | Lowers costs associated with defects and rework. |

Key Materials Used in Plastic Injection Molds and Their Impact on Product Quality

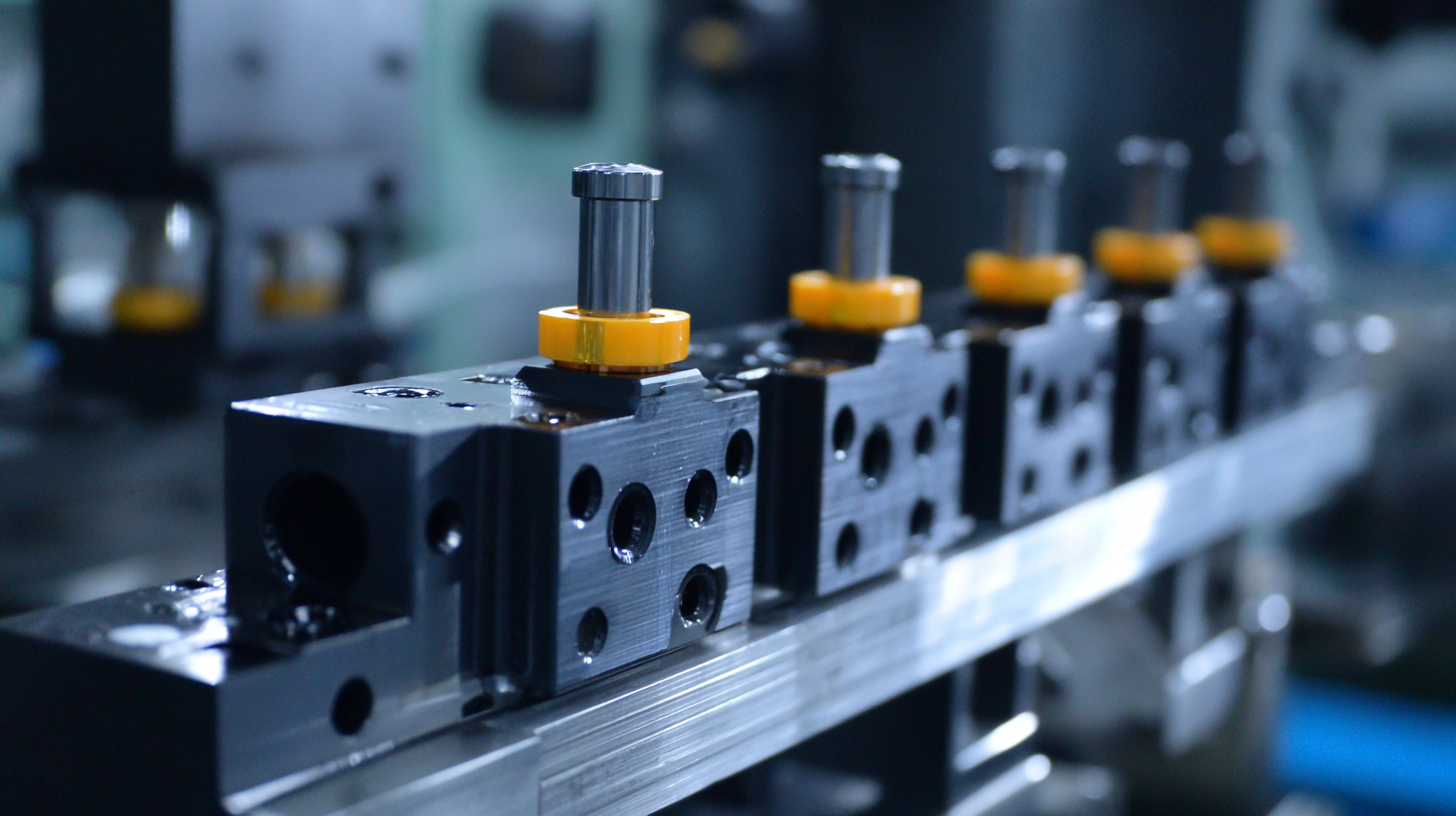

Plastic injection molds play a critical role in modern manufacturing processes, particularly in the production of high-quality plastic components. The materials used in these molds significantly impact the overall product quality, influencing factors such as durability, surface finish, and precision.

Common materials include steel and aluminum, each offering distinct advantages. Steel molds, known for their longevity and ability to withstand high pressure and temperature variations, are ideal for larger production runs. In contrast, aluminum molds, which are easier to machine and often more cost-effective, are preferred for shorter runs and prototypes.

The choice of mold material not only affects the efficiency of the manufacturing process but also the final product's performance. For instance, the thermal conductivity of the mold material can enhance the cooling rate of the injected plastic, leading to shorter cycle times and improved dimensional stability. Additionally, the hardness and wear resistance of the mold material determine how well the mold can maintain its shape and detail over time, ultimately impacting surface quality and finish. Understanding these material properties enables manufacturers to make informed decisions that enhance product quality and reliability.

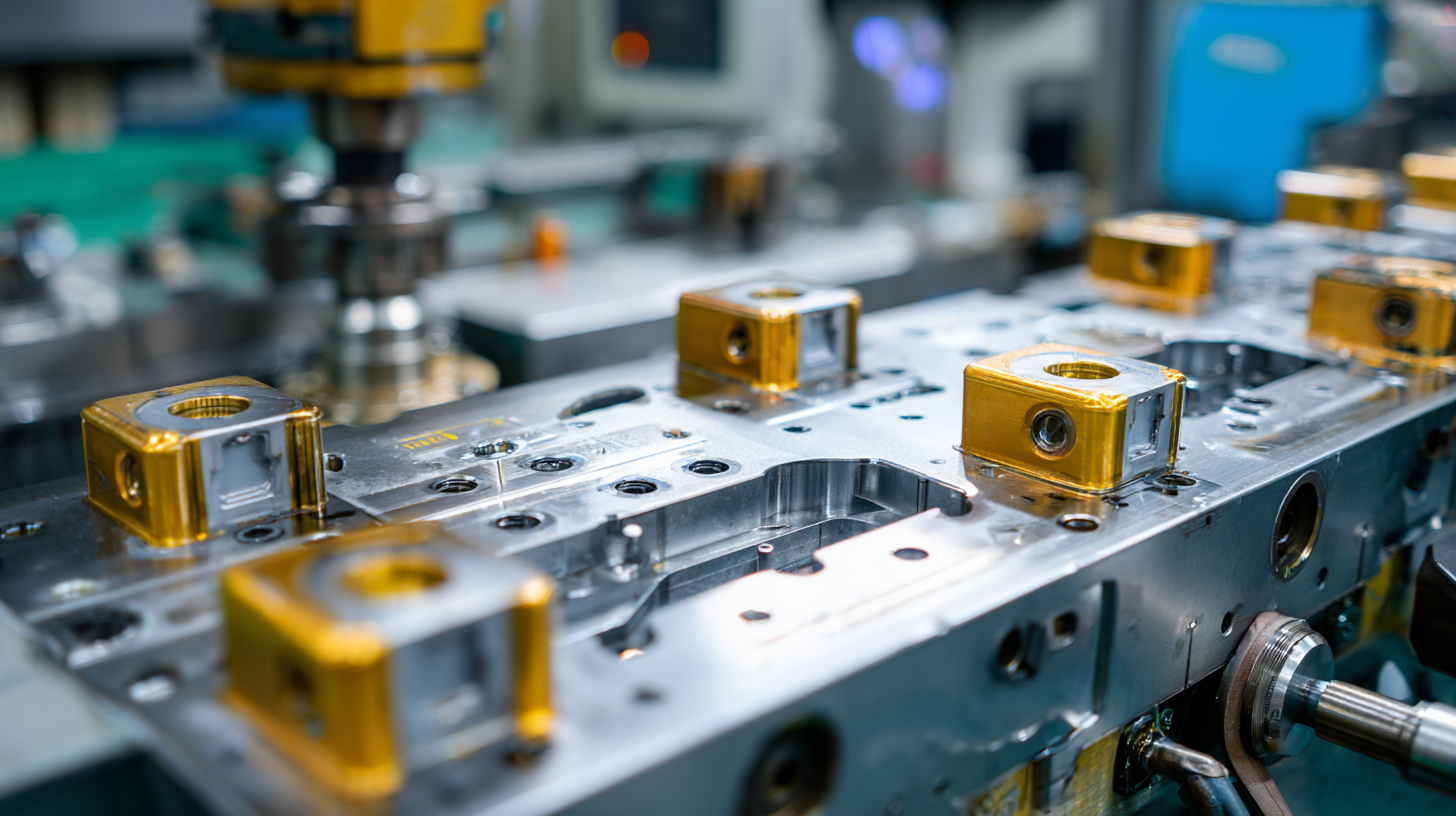

Step-by-Step Process of Designing and Fabricating Injection Molds

Designing and fabricating plastic injection molds is a critical step in modern manufacturing, particularly as the industry moves towards more efficient production methods. The process begins with conceptual design, where engineers use computer-aided design (CAD) software to create intricate mold structures tailored to the specifications of the desired parts. According to a 2022 industry report by MarketsandMarkets, the plastic injection molding market is projected to reach $395.2 billion by 2026, highlighting the increasing demand for precision-engineered components.

Once the design is finalized, the fabrication process follows. This involves the selection of appropriate materials, often tool steels or aluminum, depending on the production volume and complexity of the mold. The molds are then manufactured using advanced machining techniques such as CNC machining, electrical discharge machining (EDM), and 3D printing for prototyping. A report from Grand View Research indicates that the use of 3D printing in mold-making can reduce lead times by up to 50%, which is vital for companies looking to remain competitive in a rapidly evolving market. Each phase of this process is crucial in ensuring the resulting molds meet stringent quality and durability standards, ultimately impacting the efficiency and cost-effectiveness of production runs.

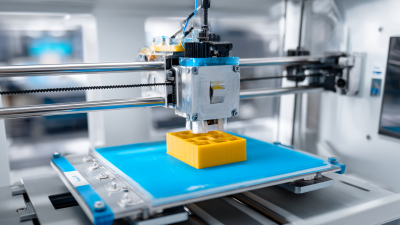

Advancements in Technology: 3D Printing and CAD in Mold Design

The integration of 3D printing and Computer-Aided Design (CAD) in mold design has revolutionized the plastic injection molding industry. With CAD software, designers can create intricate mold specifications and simulate the injection processes to identify potential issues before physical production. This digital approach enhances precision and allows for rapid iterations, significantly reducing the time and cost associated with traditional mold-making methods.

Meanwhile, 3D printing technology complements CAD by enabling the rapid prototyping of molds. Designers can produce prototype molds swiftly, facilitating quicker feedback and adjustments. This flexibility not only streamlines the development process but also opens up new possibilities for complex geometries that were previously difficult to achieve. As these technologies continue to evolve, they empower manufacturers to create more sophisticated products while maintaining efficiency and minimizing waste.

Sustainability Considerations: Reducing Waste in Injection Molding Processes

The injection molding process is a cornerstone of modern manufacturing, but its sustainability can often be overlooked. As industries are increasingly held accountable for their environmental impact, reducing waste in injection molding has become a priority. According to a report by the International Journal of Environmental Research and Public Health, efficient mold design and advanced recycling techniques can decrease waste generation by up to 30%. Companies can adopt practices such as optimizing cycle times and material usage, leading to more sustainable operations while still maintaining product quality.

Tips: Regularly auditing your production process can help identify key areas where waste can be minimized. Investing in high-quality molds, which have longer lifespans, can significantly reduce scrap rates and material costs over time.

Moreover, the introduction of bioplastics and innovative materials plays a crucial role in enhancing sustainability in injection molding. Research from the Plastics Industry Association indicates that using recycled plastics can lower the carbon footprint associated with production processes by approximately 70%. Embracing these materials not only benefits the environment but can also meet the growing consumer demand for eco-friendly products.

Tips: Consider collaborating with suppliers who specialize in sustainable materials to explore alternative options that align with your manufacturing goals. Engaging in industry partnerships can also facilitate knowledge sharing and innovation in sustainable practices.

Related Posts

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China