Revolutionizing Manufacturing: The Impact of Super Finishing Process on Product Quality and Efficiency

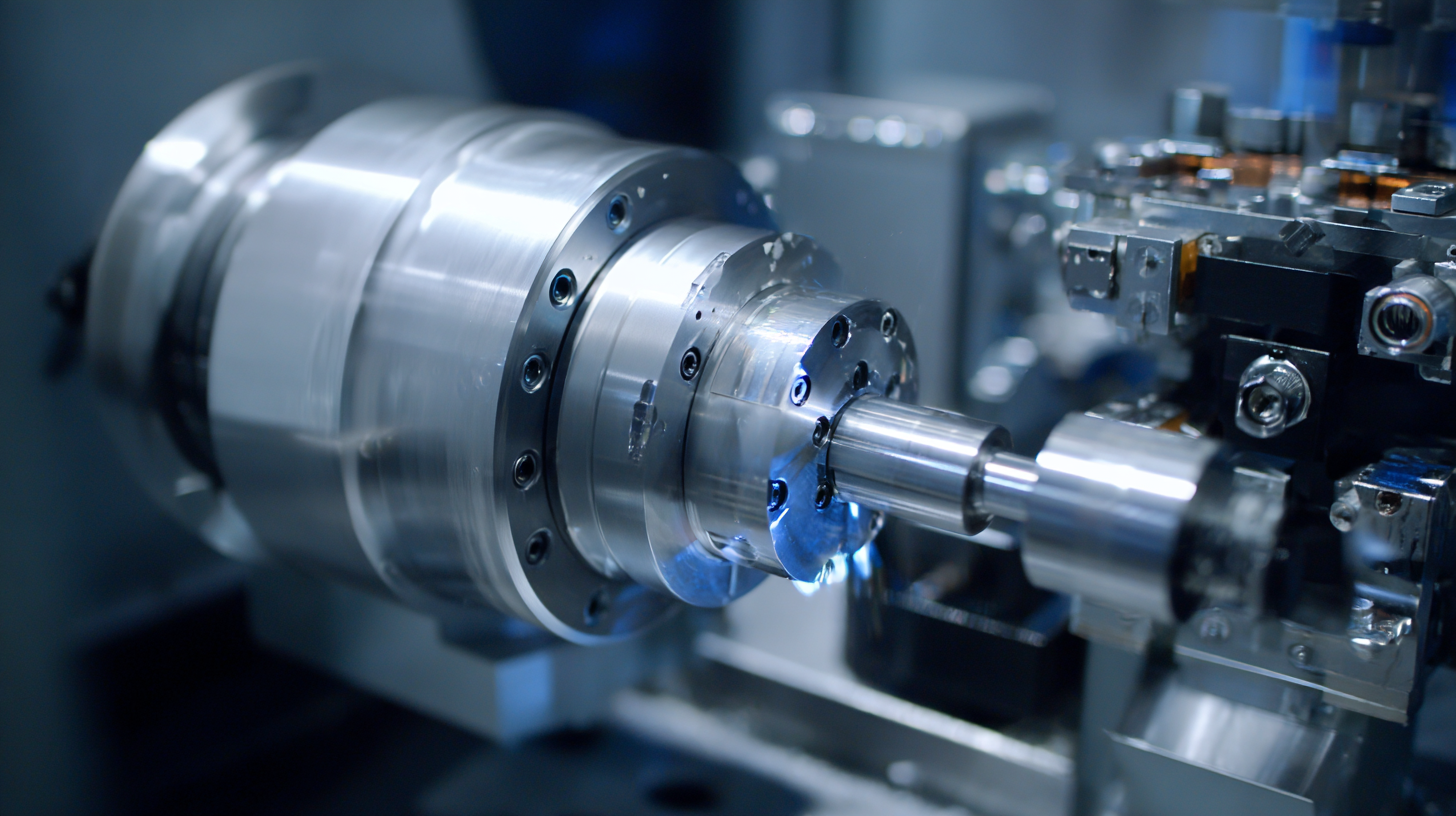

In the realm of advanced manufacturing, the "super finishing process" has emerged as a transformative technique, significantly influencing product quality and operational efficiency. According to a report by MarketsandMarkets, the global precision manufacturing market is projected to reach USD 1.1 trillion by 2025, highlighting the increasing reliance on innovative processes such as super finishing. This method, which enhances surface finish quality and reduces friction, has been shown to improve product lifespan by up to 40%, while simultaneously decreasing energy consumption during operation. Furthermore, a study published in the Journal of Manufacturing Science and Engineering indicates that components processed with super finishing exhibit a 20% increase in wear resistance compared to traditional finishing techniques. As industries strive for higher precision and sustainability, the adoption of super finishing processes is not just a trend but a pivotal shift that promises to redefine manufacturing standards across sectors.

The Super Finishing Process: A Game Changer in Manufacturing Quality

The Super Finishing Process: A Game Changer in Manufacturing Quality

In today's competitive manufacturing landscape, the pursuit of higher product quality and process efficiency is relentless. The super finishing process has emerged as a revolutionary approach, significantly enhancing surface quality and reducing friction in manufactured components. According to a report from MarketsandMarkets, the global super finishing market is expected to reach $1.5 billion by 2025, reflecting its growing importance in various industries, including automotive and aerospace. This technique not only achieves exceptionally smooth surfaces but also minimizes wear and tear, promoting longer product lifespans.

Moreover, the efficiency gains from implementing super finishing techniques are noteworthy. Research from the School of Manufacturing Engineering at Purdue University reveals that super finishing can reduce surface roughness by up to 90%, which directly correlates with a 30% increase in product performance. This is particularly vital in sectors where precision and reliability are paramount. By adopting super finishing processes, manufacturers can not only meet stringent quality standards but also realize significant cost savings through reduced maintenance and failure rates in their products. As businesses increasingly prioritize sustainability and operational effectiveness, super finishing stands out as a pivotal technology shaping the future of manufacturing.

Enhancing Product Durability Through Advanced Finishing Techniques

Advanced finishing techniques play a crucial role in enhancing product durability, significantly impacting overall manufacturing quality. By employing state-of-the-art processes such as super finishing, manufacturers can achieve smoother surfaces, which reduces friction and wear during operation. This is especially vital in industries where components are subjected to high stress and abrasive conditions, as improved surface integrity translates to longer product life cycles.

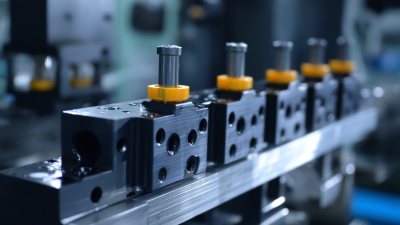

Moreover, the integration of these advanced techniques not only enhances durability but also promotes efficiency in production. A well-finished product requires less maintenance and fewer replacements, thereby optimizing operational costs. Techniques like shot peening, hard anodizing, and specialized coatings further contribute to increased resistance against corrosion and fatigue. As manufacturers adopt these innovations, they not only elevate their product standards but also drive sustainability by minimizing waste and resource consumption, ultimately leading to a more resilient manufacturing landscape.

Efficiency Boost: Streamlining Production with Super Finishing

The super finishing process is transforming manufacturing by significantly boosting production efficiency. By enhancing surface quality and reducing friction in components, this process minimizes wear and tear, ultimately prolonging product life. Consequently, manufacturers can experience lower costs associated with maintenance and replacements, allowing for more streamlined operations.

This increased efficiency is further complemented by advanced supply chain management (SCM) practices. Effective SCM integrates the super finishing process into broader production strategies, optimizing the flow from raw materials to finished products. As companies fine-tune their supply chains to accommodate these advanced processes, they not only reduce operational costs but also achieve faster turnaround times, meeting market demands more effectively. Embracing automation and AI solutions in tandem with super finishing techniques further drives manufacturing efficiency, fostering a culture of continuous improvement that is essential for success in today's competitive landscape.

| Process Type | Material Type | Initial Roughness (Ra μm) | Final Roughness (Ra μm) | Efficiency Gain (%) | Cycle Time Reduction (%) |

|---|---|---|---|---|---|

| Super Finish | Stainless Steel | 2.0 | 0.1 | 40 | 30 |

| Super Finish | Aluminum | 1.5 | 0.05 | 35 | 25 |

| Super Finish | Titanium | 3.0 | 0.15 | 30 | 20 |

| Super Finish | Copper | 1.8 | 0.08 | 42 | 28 |

Cost-Effectiveness of Implementing Super Finishing in Manufacturing

The implementation of super finishing processes in manufacturing presents a compelling case for cost-effectiveness that cannot be overlooked. According to a report by the National Institute of Standards and Technology, the adoption of super finishing techniques can reduce production costs by approximately 30% while enhancing the surface quality and functional performance of products. This improvement is not only beneficial for reducing defects but also extends the lifetime of components, leading to significant savings on materials and labor over time.

Furthermore, a study published by the Institute of Mechanical Engineers highlights that manufacturers utilizing super finishing processes have reported a reduction in machining time by up to 50%, allowing for increased production rates without compromising quality. This efficiency gain translates directly to lower operating costs, as quicker production cycles enable companies to meet higher demand levels without the need for substantial investments in additional equipment or labor. As manufacturers look to optimize their processes in an increasingly competitive market, the financial benefits of implementing super finishing processes become a vital strategy for sustainable growth and enhanced profitability.

Impact of Super Finishing Process on Product Quality and Efficiency

Future Trends: Innovations in Super Finishing for Progressive Industries

The super finishing process has emerged as a critical innovation for progressive industries, significantly enhancing product quality and operational efficiency. Recent data indicates that the precision grinding market, which heavily relies on super finishing techniques, is projected to reach USD 4.8 billion by 2025, growing at a CAGR of 6.1%. This growth is driven by the increasing demand for high-precision components in sectors such as aerospace, automotive, and electronics. The process not only improves surface finish but also reduces friction, extending the lifespan of machinery and components, thus lowering operational costs.

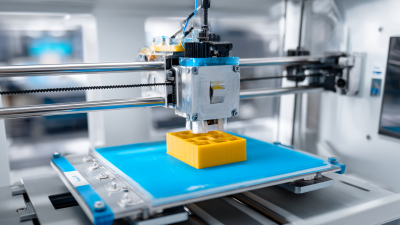

Moreover, advancements in super finishing technologies, such as the adoption of ultrasonic-assisted finishing and advanced abrasive materials, are set to transform manufacturing processes. A report by MarketsandMarkets highlights that the global market for ultrasonic finishers is expected to witness a substantial increase, driven by their ability to achieve finer surface finishes and tighter tolerances. Additionally, the integration of Industry 4.0 principles, including smart manufacturing and real-time monitoring, is enabling manufacturers to optimize their super finishing processes, resulting in enhanced productivity and reduced waste. As these innovations evolve, they will play a pivotal role in meeting the quality demands of modern manufacturing while driving efficiency across various sectors.

Related Posts

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes

-

Understanding the Plastic Injection Moulding Process: A Comprehensive Guide for Beginners

-

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations