Why is Surface Finishing Process Essential for Product Quality?

The surface finishing process is a crucial element in manufacturing that significantly impacts product quality, durability, and performance. According to a report by MarketsandMarkets, the global surface finishing market is projected to reach $9.48 billion by 2025, growing at a CAGR of 6.3% from 2020. This growth underscores the increasing recognition among manufacturers of the importance of refining final product surfaces to enhance aesthetics, reduce friction, and prevent corrosion.

Moreover, various studies have shown that products with superior surface finishes can lead to lower maintenance costs and improved customer satisfaction. For instance, a study published by the Journal of Applied Surface Science indicates that up to 30% of product failures can be attributed to inadequate surface treatment. As industries strive for higher performance and enhanced sustainability, the necessity of effective surface finishing processes becomes even more pronounced. This trend highlights the pivotal role surface finishing plays in ensuring that products not only meet but exceed quality standards, thereby maintaining competitive advantage in the marketplace.

Importance of Surface Finishing in Enhancing Product Durability and Performance

Surface finishing processes play a critical role in enhancing product durability and performance across various industries. According to a report by Industry Research, over 70% of manufacturing companies recognize that effective surface treatment can lead to a significant increase in product lifespan, ultimately reducing replacement costs and waste. Techniques such as polishing, coating, and anodizing not only improve aesthetics but also provide essential protective barriers against corrosion and wear, thereby prolonging the operational efficiency of components.

For manufacturers focusing on high-performance applications, the benefits of surface finishing cannot be overstated. A study published by the Journal of Materials Science indicates that products coated with advanced surface finishes can achieve performance gains of up to 50% in harsh environments. This enhancement is particularly crucial in sectors like aerospace and automotive, where reliability is paramount. Implementing advanced surface finishing can thus be seen as a strategic investment in quality.

**Tips:** Always assess the specific requirements of your product when selecting a surface finishing technique. Conducting thorough tests can help determine the most effective method for your application. Additionally, regular maintenance of finished surfaces can further enhance their durability, ensuring optimal performance over time.

Role of Surface Finishing in Aesthetic Appeal and Market Competitiveness

Surface finishing plays a pivotal role in enhancing the aesthetic appeal of products across various industries, contributing significantly to market competitiveness. For instance, the global market for wood veneer is projected to grow from $16.36 billion in 2024 to $20.31 billion by 2032, showcasing a compound annual growth rate (CAGR) of 2.7%. A well-finished wood veneer not only boosts the visual quality of furniture and interiors but also elevates brand perception in a competitive marketplace.

In the ceramic tile sector, the shift towards digitally printed tiles reflects a growing demand for intricate designs that enhance aesthetic value. This trend is projected to foster market growth, aligning with the increase in consumer preference for personalized and visually striking products. Furthermore, the stainless steel shot media market, valued at $150 million in 2022, is expected to rise to $280 million by 2030, at an impressive CAGR of 8.5%. This surge is largely driven by the superior aesthetic and functional characteristics that stainless steel finishes provide, particularly in industries requiring high-standard durability and design elegance. These figures underline the essential nature of surface finishing in achieving aesthetic appeal and sustaining competitive advantage across various markets.

Impact of Surface Finishing on Product Safety and Reliability

Surface finishing is a crucial step in the manufacturing process that significantly impacts product safety and reliability. According to the International Journal of Advanced Manufacturing Technology, more than 80% of manufacturing defects arise from poor surface quality. These defects can lead to catastrophic failures, especially in industries such as aerospace and automotive, where even a minor flaw can compromise safety. For instance, the Federal Aviation Administration (FAA) emphasizes that surface defects in critical components can reduce fatigue strength by up to 30%, ultimately affecting an aircraft's overall performance and safety.

Moreover, the reliability of a product is often correlated with its surface finish. A study by the National Institute of Standards and Technology (NIST) found that improvements in surface finish could enhance the fatigue life of metallic components by up to 25%. This improvement not only ensures longer service life for products but also reduces maintenance costs and the likelihood of unexpected failures. Industries investing in advanced surface finishing technologies, such as laser treatment or electroplating, are not only meeting regulatory standards but are also ensuring that their products operate safely under the most rigorous conditions. The emphasis on superior surface finishing is becoming increasingly vital for maintaining competitive advantage while prioritizing customer safety.

Why is Surface Finishing Process Essential for Product Quality? - Impact of Surface Finishing on Product Safety and Reliability

| Surface Finishing Type | Key Benefits | Impact on Safety | Impact on Reliability | Common Applications |

|---|---|---|---|---|

| Electropolishing | Improves corrosion resistance and surface cleanliness | Reduces risk of contamination | Enhances longevity of components | Medical devices, food processing equipment |

| Anodizing | Increases surface hardness and wear resistance | Improves electrical insulation | Provides consistent performance in harsh conditions | Aerospace, automotive parts |

| Powder Coating | Durable finish with a wide range of colors | Protects against rust and UV damage | Enhances structural integrity | Furniture, appliances, automotive parts |

| Plating | Enhances appearance and provides corrosion resistance | Improves electrical conductivity | Increases lifespan of components | Electrical contacts, plumbing fixtures |

| Sanding and Polishing | Provides a smooth finish | Reduces friction and potential failure points | Promotes consistent performance | Consumer goods, automotive interiors |

Integrating Advanced Technologies in Surface Finishing Processes

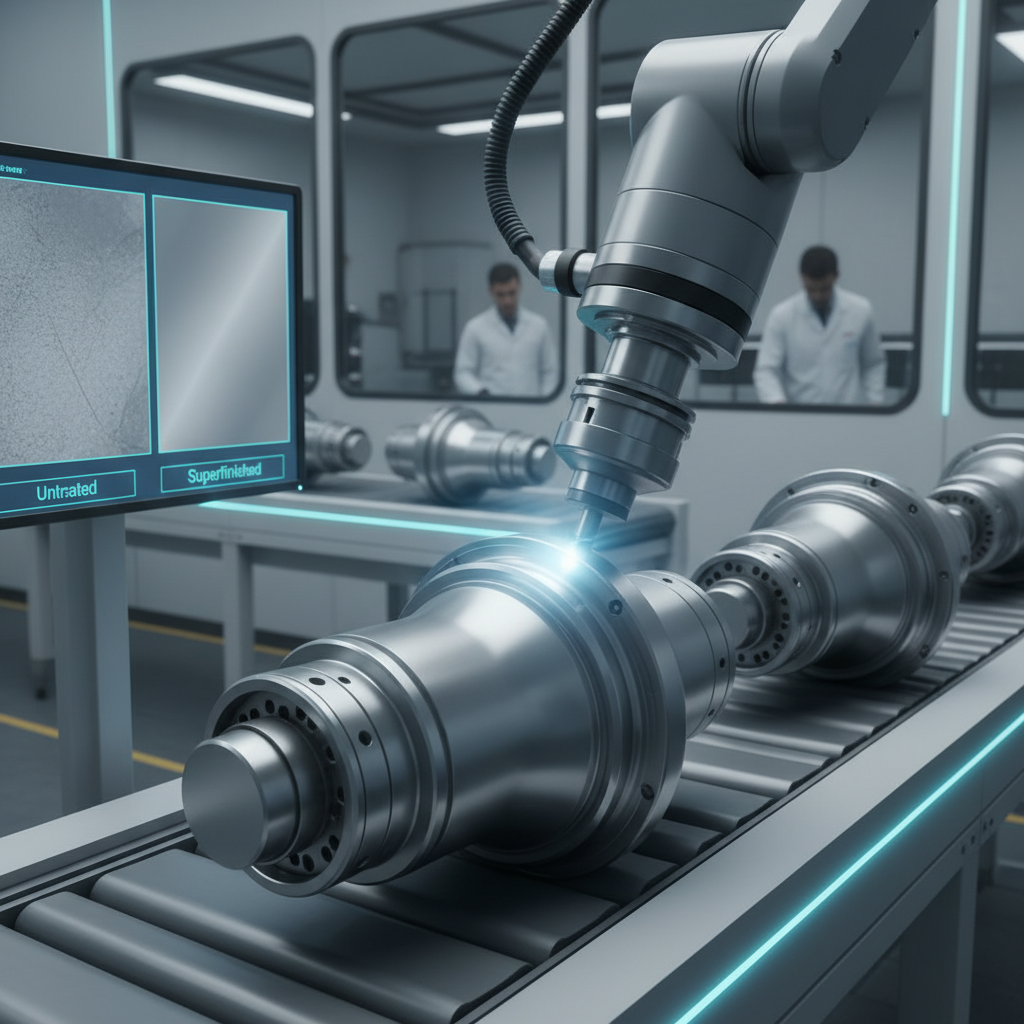

In recent years, the integration of advanced technologies into surface finishing processes has revolutionized product quality in various manufacturing sectors. Techniques such as laser finishing, robotic polishing, and automated grinding systems enhance precision and consistency, minimizing human error. These technologies enable manufacturers to achieve finer surface textures and more uniform coatings, which are crucial for functionality and aesthetics in products ranging from aerospace components to consumer electronics.

Moreover, the adoption of digital technologies like IoT and AI analytics in surface finishing allows for real-time monitoring and adjustment of processes. By leveraging data-driven insights, manufacturers can optimize their finishing operations, reduce waste, and improve resource efficiency. The ability to predict and address potential issues before they become significant problems not only enhances product quality but also streamlines production timelines. As industries continue to demand higher standards, the integration of advanced technologies in surface finishing processes becomes increasingly essential for maintaining competitiveness and ensuring customer satisfaction.

Impact of Surface Finishing Processes on Product Quality

This chart illustrates the influence of various surface finishing processes on product quality across different industries. The data highlights the performance metrics achieved through advanced technologies in surface finishing.

Cost-Effectiveness of Quality Maintenance through Surface Finishing Techniques

Surface finishing processes are crucial not only for enhancing the aesthetic appeal of products but also for ensuring long-term functionality. According to a report by the National Institute of Standards and Technology (NIST), quality defects in manufacturing can lead to costs that exceed 20% of total operational expenses. By incorporating effective surface finishing techniques, companies can significantly reduce these defects and ensure higher customer satisfaction.

Investing in quality maintenance through surface finishing not only improves product longevity but also yields significant cost savings over time. A study published by the Journal of Manufacturing Science and Engineering highlighted that implementing precise surface treatments could improve component lifespan by up to 50%. This enhancement translates to lower replacement and maintenance costs, fostering a more sustainable production cycle. Companies that prioritize surface finishing techniques are able to sustain competitive advantage while adhering to high-quality standards, ultimately leading to better profitability and market positioning.

Related Posts

-

Understanding the Plastic Injection Moulding Process: A Comprehensive Guide for Beginners

-

2025 Top Machining Tools: Revolutionizing Precision and Efficiency in Manufacturing

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Exploring Innovation: How Plastic Industries are Shaping Sustainable Technology for the Future

-

Understanding the Future of Plastic Components in Sustainable Manufacturing Processes

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations