Top 10 Tips for Understanding Additive Manufacturing Processes

Additive manufacturing processes are transforming industries. According to a report by Wohlers Associates, the global additive manufacturing market was projected to reach $23 billion by 2023. This growth reflects a significant shift from traditional manufacturing methods. As businesses adopt these technologies, understanding the nuances becomes crucial.

The benefits of additive manufacturing are evident. It allows for complex geometries and customizations that traditional methods struggle to produce. However, challenges remain. Issues such as material limitations and post-processing requirements often complicate implementation. Many companies find themselves unprepared, leading to costly errors.

Additionally, the knowledge gap in additive manufacturing processes can hinder progress. The lack of skilled professionals contributes to inefficiencies and project delays. Organizations must prioritize education and training to bridge this gap. Overall, while the potential is vast, navigating this evolving landscape requires a careful and informed approach.

Understanding Different Additive Manufacturing Technologies and Their Applications

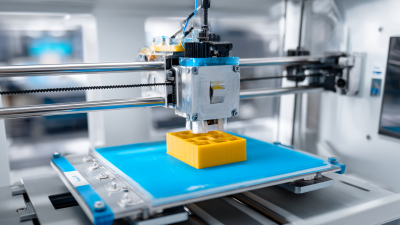

Additive manufacturing (AM) technologies are reshaping industries. They offer unique advantages, but understanding their complexities is crucial. There are several key methods, such as Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS). Each has distinct applications and limitations.

FDM is widely used for prototyping. It builds objects layer by layer using thermoplastic materials. However, parts made this way may lack durability. In contrast, SLS uses a laser to fuse powdered materials. This method can create more robust components with intricate geometries. A recent industry report states that the SLS market is expected to grow at a CAGR of 23.5% from 2022 to 2026, highlighting its increasing relevance.

Other technologies, like Stereolithography (SLA), are ideal for creating detailed prototypes. Yet, SLA's materials can be cost-prohibitive. As the field evolves, there's a need for more accessible solutions. Companies often face challenges in choosing the right technology for their needs. The results can vary significantly. In this context, reflecting on past choices is essential for future success.

Key Materials Used in Additive Manufacturing: Properties and Performance Metrics

Additive manufacturing, commonly known as 3D printing, relies on various materials to achieve desired performance. The choice of material is crucial for the success of any project. Common materials include plastics, metals, and ceramics. Each material has unique properties that influence the final product's strength and functionality. For instance, thermoplastics like ABS and PLA are popular for their ease of use and affordability, but they may not always withstand high temperatures.

Metals such as titanium and stainless steel offer superior mechanical properties. According to a report by Wohlers Associates, titanium parts produced through additive manufacturing exhibit exceptional strength-to-weight ratios. However, these materials can also be challenging to process. They often require specialized equipment and conditions. Understanding the performance metrics of these materials is essential for engineers. It aids them in predicting how a component will behave in real-world applications.

Ceramics are gaining attention due to their high heat resistance. However, they can be brittle. This presents a challenge during the manufacturing process. The difficulty in achieving consistent quality often leads to trial and error. This points to an ongoing need for innovation in material science. It raises questions about the balance between performance and practicality in additive manufacturing.

Comparative Analysis of Additive vs. Traditional Manufacturing Costs and Efficiency

Understanding the cost dynamics of additive manufacturing compared to traditional methods reveals notable differences. Additive manufacturing often requires lower initial investment. Machines can be more affordable, especially for small-scale production. However, the operational costs can vary significantly depending on material use and design complexity. For instance, intricate designs may drive up material costs despite reduced waste.

On the other hand, traditional manufacturing often has higher setup expenses. Large-scale production becomes cost-efficient quickly. Yet, the speed of additive manufacturing allows for rapid prototyping. This means companies can pivot and innovate without significant delays. Still, the trade-off is evident: while additive methods can minimize waste, they sometimes rely on expensive materials.

Both processes come with their own challenges. Additive manufacturing might not achieve the same level of finish as traditional methods. Users must carefully assess these trade-offs. Understanding these aspects can lead to more informed decisions in manufacturing strategies.

Comparative Analysis of Additive vs. Traditional Manufacturing Costs and Efficiency

Critical Role of Design for Additive Manufacturing in Product Development

Design for Additive Manufacturing (DfAM) plays a crucial role in product development. In the past decade, the additive manufacturing market grew to over $12 billion. Effective DfAM enables companies to adapt designs that maximize the benefits of 3D printing. It's not just about creating complex shapes; it’s about understanding material behavior and printing constraints.

Studies show that approximately 70% of production costs stem from design mistakes. These errors can lead to inefficiencies in materials and resources. When designs do not consider the layer-by-layer buildup in additive manufacturing, issues can arise. Support structures may be needed, which can increase material waste.

The integration of DfAM practices can reduce lead times significantly. Research indicates that utilizing DfAM can cut development time by up to 50%. However, there's still a disconnect. Many engineers lack proper training in DfAM principles. This gap leaves room for improvement in how products are conceptualized. Rethinking conventional design methods is essential for leveraging the full potential of additive manufacturing.

Regulatory Standards and Quality Control Measures in Additive Manufacturing Processes

In additive manufacturing, regulatory standards and quality control are paramount. These processes involve layers of materials, making precision vital. Different industries have various guidelines. For example, the aerospace sector demands high safety standards. Compliance with these standards is not always straightforward. Manufacturers face challenges in consistently meeting these requirements.

Quality control measures in additive manufacturing include regular inspections. Each production batch should undergo stringent testing. Many companies use software to monitor processes. This helps identify defects early. However, relying solely on technology can be problematic. Human oversight is still necessary. Errors can arise from misinterpretation of data.

Documentation is also crucial. Detailed records of each step must be kept. This transparency enhances accountability. Still, managing extensive data can overwhelm teams. Balancing thoroughness with efficiency is a constant struggle. Quality control in additive manufacturing is an evolving field. Manufacturers must remain adaptable to meet regulatory demands.

Related Posts

-

Top 10 Benefits of Additive Manufacturing Technology in Modern Industry

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

What Types of Manufacturing Applications Are Transforming Industry Today?

-

How to Achieve Superior Results with Super Finishing Techniques

-

2025 How to Choose the Right Injection Tooling for Your Manufacturing Needs

-

How to Choose the Right Machining Tools for Your Project Success