The Best 10 Plastic Mold Techniques You Should Know?

In the world of manufacturing, plastic mold techniques play a crucial role. The global plastic mold market was valued at over $25 billion in 2022 and is expected to grow significantly. This growth highlights the importance of modern techniques in meeting industrial demands.

Plastic molds are not just about production; they also enhance efficiency and precision. Each technique offers unique benefits. For instance, injection molding is favored for its speed and volume production. Blown film molding, on the other hand, is essential for creating flexible packaging. These methods address real-world challenges but can also lead to waste and inefficiency if not executed correctly.

Navigating the landscape of plastic mold can be daunting. Even experienced professionals can struggle with choosing the right technique. It's crucial to evaluate each method. The choice impacts not only product quality but also sustainability. Reflecting on this, companies must adapt and innovate to thrive in a competitive market.

Understanding Plastic Molding: A Comprehensive Overview

Understanding plastic molding is essential for those involved in manufacturing. This process allows for the creation of a wide range of products. From toys to automotive parts, plastic molding supports innovation. Various techniques are used in plastic molding, each with unique advantages.

One common method is injection molding. This technique is efficient and widely used. It involves heating plastic until it melts and then injecting it into a mold. The cooling process solidifies the shape. However, the initial setup can be costly. Designers must ensure molds are precise. Any mistakes in design can lead to wasted materials.

Another technique is blow molding. This method is often used for making containers. It forms plastic into a parison, which is inflated into a mold. While effective, it requires careful attention to wall thickness. Uneven thickness can result in weak spots.

Tips:

1. Always prototype before mass production. This step can identify design flaws early.

2. Keep a checklist for mold requirements. It helps maintain standards and ensures quality.

3. Communicate with your manufacturing team regularly. Their insights can greatly improve the molding process.

These considerations are crucial for anyone looking to excel in the plastic molding industry. Attention to detail is key. Mistakes can happen, but learning from them leads to improvement.

The Best 10 Plastic Mold Techniques You Should Know

The Different Types of Plastic Mold Techniques Explained

When it comes to plastic mold techniques, understanding the different methods is crucial. Each technique has its own strengths and weaknesses. For instance, injection molding is popular due to its efficiency and precision. It can produce complex geometries quickly, but requires significant upfront cost. This can pose a challenge for small projects or startups.

Blow molding is another technique to consider. It's great for hollow objects, like bottles. This technique is relatively fast, but it has limitations in design flexibility. Sometimes, issues arise with uneven wall thickness. This can lead to structural weaknesses in the final product.

Rotational molding is an interesting option for large items. This method involves rotating a mold loaded with plastic. It allows for more uniform thickness, but the cycle time is longer. The trade-off between speed and quality needs careful consideration. Analyzing these techniques can help you select the best one for your specific needs.

Step-by-Step Guide to Injection Molding Process

Injection molding is a vital process in plastic manufacturing. It starts with heating plastic pellets until they melt. This melted plastic is then injected into a mold. The mold shapes the plastic into a specific form. After cooling, the mold opens to reveal the new product. Timing is crucial. Allowing too little or too much time can ruin the final product.

Once the mold opens, inspection is necessary. Small defects can occur, leading to waste. Sometimes, adjustments to the mold are needed. It’s essential to track these errors. Analyzing them helps improve the process. Understanding the right temperature and pressure is also critical. Too much pressure may lead to flash, while too little can result in incomplete fills.

Proper maintenance of molds is important. Regular cleaning can prevent issues that may arise from residue build-up. Tools used for injection molding should be in good condition. Neglecting maintenance can lead to costly downtime. Continuous learning and adaptability are keys. Each batch provides new insights into improving efficiency and quality.

Exploring Blow Molding: Techniques and Applications

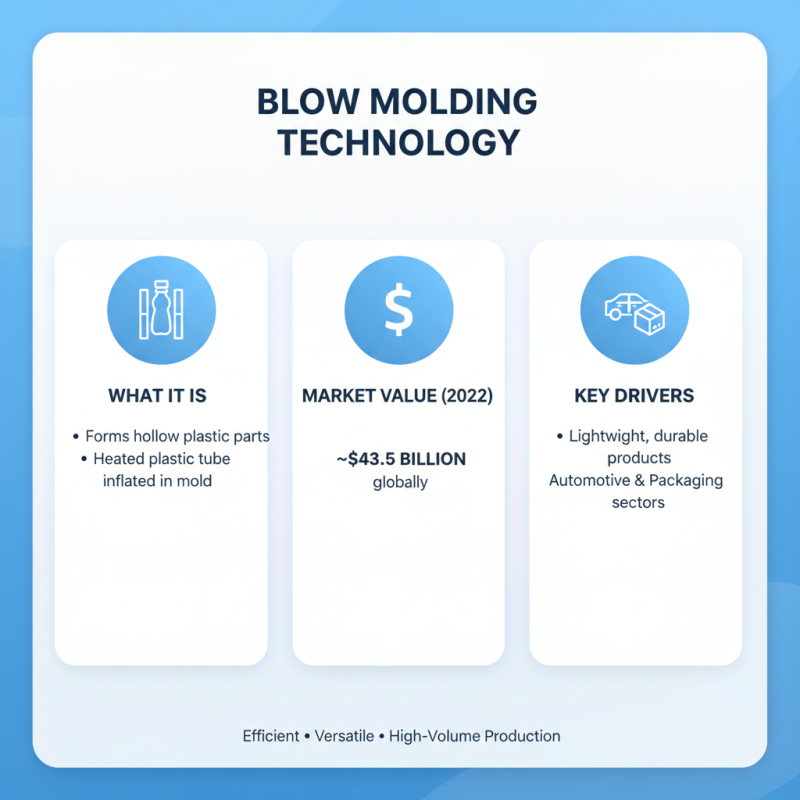

Blow molding is a widely used technique in the plastics industry, known for its efficiency and versatility. This method involves forming a hollow plastic part by inflating a heated plastic tube until it takes the shape of a mold. In 2022, the global blow molding market was valued at approximately $43.5 billion. The demand for lightweight, durable products in sectors like automotive and packaging drives this growth.

One popular application of blow molding is in creating plastic bottles. According to industry reports, over 80% of all blow-molded products fall into this category. However, precision in temperature control and mold design is critical. Mistakes in these areas can lead to defects, such as uneven wall thickness and weak points in the product. These issues highlight the necessity for manufacturers to continuously evaluate their processes.

Tips: When designing blow-molded products, make sure to consider material properties. Testing different plastics can reveal which best meets your needs. Additionally, regular maintenance on molds can prevent costly downtime. Companies that prioritize quality assurance often outperform competitors. By focusing on detail, you can avoid common pitfalls in blow molding.

Benefits of Using Rotational Molding in Manufacturing

Rotational molding is a fascinating technique that offers various benefits in manufacturing. It allows for the creation of complex shapes with consistent wall thickness. This method is particularly effective for producing large parts that require durability. Examples include storage tanks and playground equipment, both made robust through this process.

One significant advantage of rotational molding is the flexibility it provides in design. Designers can create intricate details without compromising strength. However, the process does have limitations. Cycle times can be longer compared to other methods, which may affect productivity. Additionally, while tooling costs can be lower, some may find the setup time daunting. It's essential to balance these factors to optimize production.

Another key benefit is the material efficiency achieved through rotational molding. Minimal waste is generated during the production process. This is crucial in today's environmentally conscious landscape. Yet, manufacturers must remember that not all materials perform equally well. Understanding material properties is essential for achieving the best results. Thus, manufacturers should continually assess their choices to improve efficiency and quality in rotational mold production.

Related Posts

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

What is Plastic Injection Mold? A Comprehensive Guide for Beginners

-

How to Achieve Superior Results with Super Finishing Techniques

-

How to Choose the Right Stamping Dies for Your Metalworking Projects

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing