Top 10 Benefits of Using the Super Finishing Process for Precision Parts?

The "super finishing process" is a pivotal advancement in precision manufacturing. This technique enhances surface quality and dimensional accuracy. As industry expert Dr. Jane Smith notes, “The super finishing process can transform raw materials into precision parts that meet rigorous standards.”

In today’s competitive market, the need for high precision is paramount. The super finishing process not only improves performance but also extends the lifespan of components. Imagine a part that is flawlessly smooth, reducing friction and wear. This meticulous attention to detail can lead to significant cost savings over time.

However, the adoption of this process brings challenges. It requires careful oversight, skilled operators, and investment in proper equipment. Not every manufacturer fully grasps the capabilities of the super finishing process. As they strive for perfection, they must also reflect on their current practices and embrace new technologies. This balance is essential for growth in the precision parts industry.

Overview of the Super Finishing Process for Precision Parts

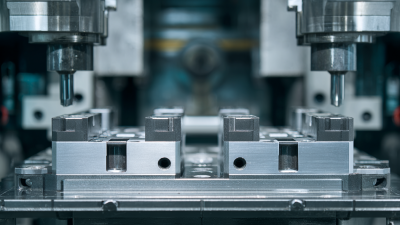

The super finishing process is a critical technique used in precision manufacturing. It enhances the surface quality of parts, providing exceptional smoothness. This process typically involves abrasive polishing to remove minor imperfections. As a result, components can achieve tighter tolerances, which improves overall functionality.

During super finishing, a small amount of material is removed. The objective is to refine the surface rather than reshape it. This nuanced approach can lead to an increase in durability. However, achieving the perfect finish can be challenging. Even experienced operators can face inconsistencies in output.

The application of this process is vast, ranging from automotive to aerospace industries. Some parts may require specific attention due to their operational environments. Not all parts benefit equally from super finishing. Each project demands careful consideration of the techniques used. Striking a balance between precision and practicality can often lead to reflective discussions among engineers.

Enhanced Surface Finish Quality Through Super Finishing

The super finishing process stands out for its ability to enhance surface finish quality significantly. This technique provides a meticulously polished surface, which is essential for precision parts. The shine isn't just for aesthetics; it improves functionality. Smoother surfaces reduce friction, leading to better performance in mechanical systems.

Imagine a finely tuned engine where every part plays a role. A rough surface could lead to wear and tear. With super finishing, parts resist corrosion better and increase longevity. It's not a one-size-fits-all solution, though. There are challenges in achieving the desired finish. Sometimes, the process can be inconsistent, requiring careful monitoring.

Moreover, achieving the perfect surface can be time-consuming. There are cases where parts come out with imperfections. Small scratches or uneven textures may still appear. These flaws remind us that precision isn't always guaranteed. The goal, however, is to mitigate these issues through constant improvement and rigorous checks. The journey to enhanced surface quality is ongoing and requires attention to detail.

Improved Dimensional Accuracy and Tolerances of Components

The super finishing process enhances the dimensional accuracy of precision parts significantly. This method can attain surface roughness levels as low as Ra 0.01 µm. Such precision is invaluable in industries like aerospace and automotive, where every micron counts. A report by the Precision Engineering Society states that using super finishing can improve tolerances by 40%. This level of accuracy reduces the risks of mechanical failures and increases part longevity.

Dimensional tolerances are critical. Tight tolerances, often within ±5 µm, are challenging to achieve. Traditional machining methods can fall short, leading to costly rework. The super finishing process addresses this issue by refining surface profiles. Additionally, it minimizes burr formation. This process not only enhances aesthetics but also ensures that parts fit together seamlessly. However, it's essential to acknowledge that achieving uniform results can depend on various factors like material type and initial surface conditions.

Intriguingly, while the benefits are clear, challenges persist. Not all components are suitable for super finishing. Some may require extensive pre-machining, driving up costs. Moreover, the skill level of operators can affect outcomes. Inconsistent practices may lead to variability in results. These nuances remind us that while technology brings improvements, critical evaluation remains essential for optimal results.

Reduction of Friction and Wear in Mechanical Applications

The super finishing process plays a crucial role in reducing friction and wear in mechanical applications. By creating a smoother surface finish, this technique minimizes surface roughness. When parts interact, less friction results in longer lifespans. Mechanical components function more efficiently, leading to decreased energy consumption. Reduced wear means less frequent replacements, ultimately lowering operational costs.

Moreover, the benefits are not always immediate. Engineers may need to analyze the long-term impacts. Sometimes, minor surface imperfections can lead to unexpected wear patterns. Regular assessment is vital to ensure that the finishing process meets desired outcomes. Embracing super finishing requires continuous improvement in techniques and quality control.

In high-performance environments, the importance of surface finish cannot be overstated. It's intriguing how a seemingly minor detail can cause significant changes. Some might overlook this process, favoring quicker, less refined methods. Yet, in the long run, investing time in super finishing pays dividends. Precision parts thrive in various applications, from automotive to aerospace, by minimizing friction and enhancing durability.

Top 10 Benefits of Using the Super Finishing Process for Precision Parts

Increased Lifespan and Reliability of Precision Parts

The super finishing process offers significant advantages for precision parts, particularly in enhancing their lifespan and reliability. This finishing technique reduces surface roughness, creating an ultra-smooth finish. Such a smooth surface minimizes friction between moving parts, leading to less wear over time. Consequently, components can endure longer under various operating conditions.

Moreover, the super finishing process can increase resistance to corrosion. Parts that resist corrosion remain functional for extended periods, even in harsh environments. However, achieving the desired finish may require several trials. Each attempt can vary in effectiveness, raising the need for ongoing examination and adjustment. It's crucial to strike the right balance between finish quality and production efficiency.

Investing time in perfecting this process pays off. Enhanced durability means fewer replacements, which translates to cost savings over time. Yet, precision and consistency in the finishing process are key. Inadequate attention can lead to variability in quality. Ultimately, focusing on these details fosters both reliability and longevity for precision parts.

Related Posts

-

How to Achieve Superior Results with Super Finishing Techniques

-

Revolutionizing Manufacturing: The Impact of Super Finishing Process on Product Quality and Efficiency

-

Top Benefits of Super Finishing Process for Precision Engineering Applications

-

What is Plastic Injection Mold? A Comprehensive Guide for Beginners

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

How to Choose the Right Injection Mold Inserts for Your Manufacturing Needs