Top 5 Industrial Applications of Technology You Should Know?

In today's fast-paced world, technology plays a crucial role in various industrial applications. These applications drive efficiency and innovation across multiple sectors. From manufacturing to logistics, technology transforms how businesses operate.

One significant advancement is the integration of automation. Robots increasingly perform tasks that were once manual. This shift can lead to higher productivity but raises concerns about job displacement. Additionally, data analytics offers insights that improve decision-making. However, reliance on data may overshadow human intuition.

Moreover, the rise of the Internet of Things (IoT) connects devices in real-time, enhancing communication within industries. Yet, security challenges persist, leaving many to wonder if the benefits outweigh the risks. As we explore the top five industrial applications of technology, it's essential to reflect on both the advantages and potential pitfalls. Understanding these factors helps businesses harness technology effectively while being aware of its limitations.

Top Industrial Applications of IoT Technology in Manufacturing Processes

The integration of IoT technology in manufacturing processes is transforming how industries operate. Smart sensors and devices connect machinery and systems. This connectivity facilitates real-time data collection. Consequently, manufacturers can monitor equipment health and performance continuously. It helps to predict failures before they escalate. For instance, if a machine shows signs of wear, maintenance can be scheduled proactively.

Data analytics plays a crucial role in this transformation. Analyzing data from various touchpoints can reveal patterns. These insights help in optimizing production processes. However, many organizations struggle with data-overload. They may lack the means to interpret this information effectively. Some might ignore the finer details, leading to missed opportunities.

Moreover, while IoT enhances efficiency, it also introduces challenges. Cybersecurity threats are a significant concern. As devices become interconnected, vulnerabilities increase. Not every organization has a robust plan to mitigate these risks. Reflection is essential as companies navigate this digital transition. The journey towards fully leveraging IoT technology is a continuous process of learning and adaptation.

Top 5 Industrial Applications of IoT Technology in Manufacturing Processes

This chart illustrates the top five industrial applications of IoT technology in manufacturing processes, showcasing their significance and distribution in the industry.

Impact of Artificial Intelligence on Predictive Maintenance in Industry

Predictive maintenance has transformed industries with the help of artificial intelligence. This technology enables companies to anticipate equipment failures before they occur. By analyzing data from sensors and historical performance, AI identifies patterns that indicate potential issues. This proactive approach reduces downtime and minimizes maintenance costs.

However, the implementation isn’t flawless. Data quality can hinder AI's effectiveness. If the input data is inaccurate, the predictions may lead to wrong decisions. Maintaining up-to-date data is challenging for many organizations. Regular audits and adjustments are necessary to ensure accuracy.

While AI's potential is significant, the human factor remains essential. Workers must interpret the insights provided by AI effectively. Relying solely on technology can lead to complacency. Training employees to respond to AI alerts is crucial for a successful predictive maintenance strategy. Balancing technology and human insight can yield the best results in industrial settings.

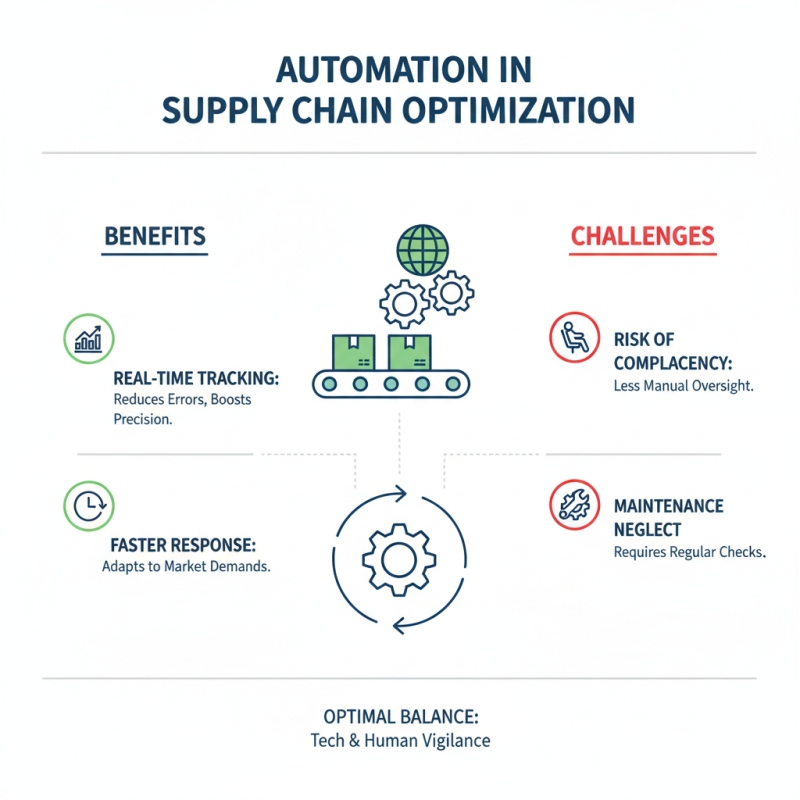

The Role of Automation in Supply Chain Optimization and Efficiency

In recent years, automation has emerged as a crucial component in supply chain optimization. Automated systems can track inventory levels in real time. This capability reduces human errors and enhances precision in stock management. It allows businesses to respond more swiftly to market demands. However, relying on automation can lead to complacency. Teams may overlook the importance of regular checks and maintenance.

Technology facilitates better communication between suppliers and manufacturers. Automated platforms can streamline order processing and logistics planning. They can also analyze data to predict future trends, allowing for proactive adjustments. Yet, overdependence on software can create vulnerabilities. Issues like technical glitches can lead to significant disruptions if not monitored closely. Continuous training for staff is essential to ensure they can effectively manage these systems.

Efficiency gains can be impressive, but it's important to recognize the limitations of automation. While automation can optimize many processes, it can’t replace human insight. Supply chains are complex and require flexibility. Emphasizing collaboration between technology and human expertise is vital for achieving the best results. Balancing these elements can drive significant improvements in overall supply chain efficiency.

Big Data Analytics in Industrial Operations: Driving Decision-Making

Big data analytics is transforming industrial operations. It enhances decision-making by providing insights from vast data sets. Companies can track performance metrics in real-time. This allows for quicker responses to emerging issues.

For instance, predictive maintenance reduces downtime. By analyzing data from machines, organizations can foresee when equipment may fail. Scheduled maintenance can then be planned in advance. However, relying solely on data can lead to overconfidence. Decisions made without human oversight may overlook critical factors.

Data security is another concern. Collecting and storing data increases vulnerability to breaches. Companies must strike a balance between leveraging data and protecting sensitive information. While technology offers immense benefits, it also demands careful consideration to avoid potential pitfalls.

Blockchain Applications for Enhancing Supply Chain Transparency and Security

Blockchain technology is transforming supply chain management. It enhances transparency and security significantly. According to a study by Gartner, 75% of enterprises are expected to adopt some form of blockchain technology by 2025. This trend is driven by the need for better traceability and trust among stakeholders.

With blockchain, every transaction is recorded on a decentralized ledger. This ensures that all parties can verify the data, reducing fraud and errors. A recent report from the World Economic Forum highlighted that blockchain could reduce supply chain costs by up to $2.5 trillion by 2025. However, implementing this technology isn't without challenges. Many companies struggle with integrating blockchain into existing systems.

Security is another critical concern. While blockchain is inherently secure, data entry remains vulnerable. If incorrect data is entered initially, it becomes difficult to trace later. The industry must focus on improving data accuracy before relying solely on blockchain solutions. This reflects the need for continuous improvement in the technology.

Top 5 Industrial Applications of Technology

| Application | Description | Benefits | Industries |

|---|---|---|---|

| Supply Chain Management | Utilizing blockchain to track products throughout the supply chain for transparency. | Enhanced transparency, reduced fraud, and improved efficiency. | Manufacturing, Retail, Logistics |

| Smart Contracts | Contracts executed automatically when conditions are met, recorded on the blockchain. | Lower transaction costs, less need for intermediaries, and increased trust. | Finance, Real Estate, Insurance |

| Asset Tracking | Using blockchain to ensure the authenticity and condition of high-value assets. | Improved asset management, reduced loss, and enhanced accountability. | Logistics, Transportation, Manufacturing |

| Product Verification | Verification of authenticity for products using blockchain records. | Reduced counterfeit products, increased customer trust. | Consumer Goods, Beverages, Pharmaceuticals |

| Data Sharing | Enabling secure and transparent data sharing across organizations via blockchain. | Enhanced collaboration, improved data integrity, and reduced data breaches. | Healthcare, Energy, Telecommunications |

Related Posts

-

2026 Best Industrial Applications for Innovative Technology Solutions?

-

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

-

What Types of Manufacturing Applications Are Transforming Industry Today?

-

Top 10 Benefits of Using the Super Finishing Process for Precision Parts?

-

Exploring Innovation: How Plastic Industries are Shaping Sustainable Technology for the Future

-

2025 How to Choose the Right Injection Tooling for Your Manufacturing Needs