Top 10 Injection Tooling Techniques for Optimal Manufacturing Efficiency

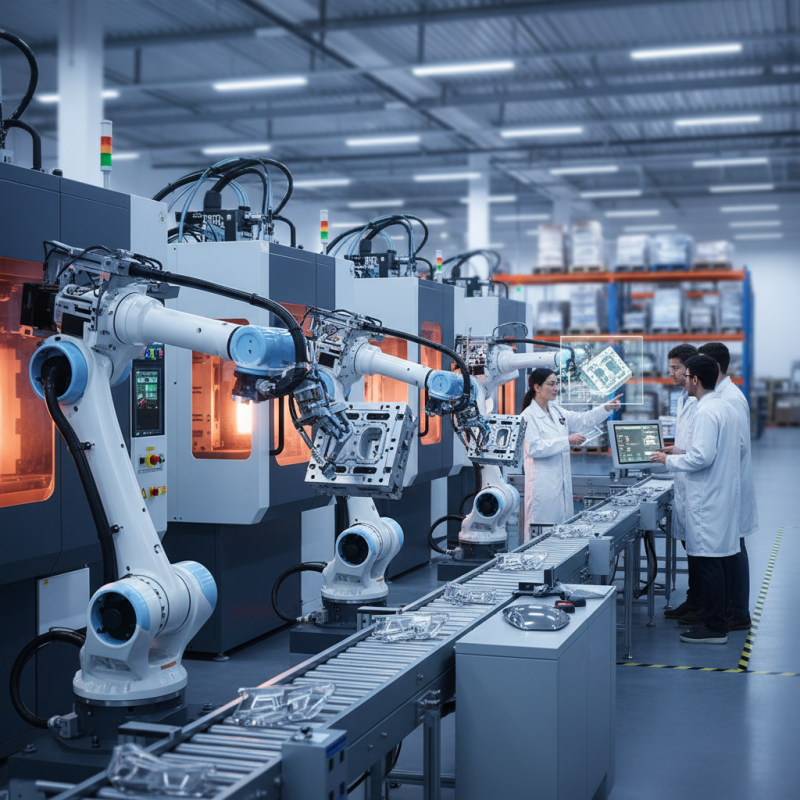

In the fast-evolving landscape of manufacturing, the importance of injection tooling techniques cannot be overstated. As industry expert Dr. Emily Chen, a leading authority on advanced manufacturing technologies, aptly stated, “The efficiency of your production line hinges on the precision and adaptability of your injection tooling solutions.” This statement underscores the critical role that effective injection tooling plays in optimizing manufacturing processes, reducing waste, and maintaining product quality.

As manufacturers strive for greater efficiency, understanding and implementing the top injection tooling techniques becomes essential. These techniques not only enhance the speed and efficiency of production but also allow for greater innovation in product design. With advancements in technology, companies have access to a myriad of tooling options that can significantly impact their operational prowess and competitiveness in the market.

In this article, we will explore the top ten injection tooling techniques that can drive optimal manufacturing efficiency. By delving into each technique, manufacturers can arm themselves with the knowledge necessary to refine their processes, adapt to market changes, and ultimately achieve superior production outcomes.

Understanding Injection Tooling in Manufacturing Processes

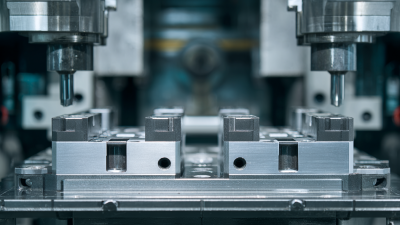

Injection tooling is a critical aspect of the manufacturing process, significantly impacting both the efficiency and quality of produced components. At its core, injection tooling refers to the molds used in the injection molding process, where melted materials, typically plastics, are injected into the molds to form desired shapes. Understanding the intricacies of injection tooling is essential for manufacturers looking to optimize production lines and minimize waste.

Effective injection tooling techniques can enhance the overall manufacturing efficiency by reducing cycle times and improving part consistency. Techniques such as optimizing mold design, selecting the right material for both the mold and the product, and implementing advanced cooling systems can lead to a streamlined manufacturing process. Moreover, the integration of automation and precision machining in the tooling process not only increases efficiency but also lowers the margin for error, ensuring that the final product meets stringent quality standards. By focusing on these aspects of injection tooling, manufacturers can achieve better resource allocation and ultimately enhance their competitive edge in the market.

Top 10 Injection Tooling Techniques for Optimal Manufacturing Efficiency

This chart displays the effectiveness of the top 10 injection tooling techniques in improving manufacturing efficiency, showcasing their impact on production cycle time and defect rates.

Key Factors Influencing Injection Tooling Efficiency

When considering the key factors influencing injection tooling efficiency, the design of the tooling itself emerges as a critical determinant. Efficient tool design minimizes cycle times while maximizing the life and performance of the tool through optimized cooling channels, precise venting, and durable materials. An effective design not only reduces the initial production costs but also lowers the maintenance requirements, ultimately contributing to higher manufacturing efficiency. In addition, ensuring that the tooling is adaptable for various production runs can significantly enhance flexibility and responsiveness to market demands.

Another essential factor is the choice of materials used in the injection process. Selecting the right polymers and additives can profoundly impact the quality and consistency of the final product. The flow properties of the chosen material affect how well it fills the mold, which influences the cycle time and precision of the part produced. Furthermore, proper material handling and processing conditions, including temperature and pressure settings, are vital to achieving optimal results. Regular monitoring of these parameters can ensure that production remains efficient and consistent, leading to reduced downtime and waste throughout the manufacturing process.

Overview of the Top Injection Tooling Techniques

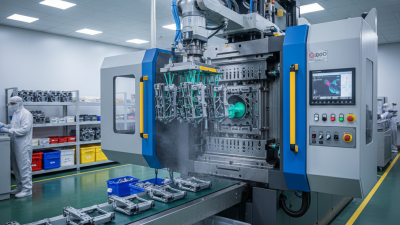

Injection tooling techniques play a vital role in enhancing manufacturing efficiency, particularly in the production of plastic components. Among the top techniques, multi-cavity molds stand out, as they allow manufacturers to produce multiple parts simultaneously within a single cycle. This approach significantly reduces cycle times and overall production costs while maintaining consistent quality across each manufactured piece. Additionally, utilizing hot runner systems can streamline the injection process by minimizing material wastage and reducing the time required for mold maintenance and cleaning.

Another effective technique is using modular tooling, which enables manufacturers to easily adapt and modify molds for different product designs without the need for extensive rework. This flexibility not only speeds up production times but also facilitates quicker responses to market demands. Furthermore, the implementation of advanced simulation software in the design phase can identify potential issues in the tooling process early on, optimizing mold layout and cooling efficiency. By integrating these innovative techniques into their operations, manufacturers can achieve higher levels of efficiency and output quality, ultimately leading to greater competitiveness in the market.

Comparative Analysis of Different Injection Techniques

The comparative analysis of different injection techniques reveals a range of methodologies that can significantly enhance manufacturing efficiency. Traditional injection molding, known for its reliability and cost-effectiveness, is often contrasted with advanced techniques such as gas-assisted injection and micro-injection molding. Gas-assisted injection provides superior part quality and reduced cycle times by utilizing gas to create hollow sections and minimize material use. On the other hand, micro-injection molding offers high precision and is essential for producing intricate components in sectors like electronics and medical devices, showcasing how different techniques cater to varying production needs.

In addition to these methods, the use of multi-material injection techniques allows for more complex product designs. This approach enables manufacturers to combine different materials into a single part, optimizing mechanical properties and expanding design possibilities. Moreover, the rise of 3D printing technology in conjunction with injection molding techniques is revolutionizing prototyping and small-scale production, as it allows for rapid development and reduced lead times. Each of these techniques emphasizes the need for manufacturers to carefully evaluate their production goals, materials, and design specifications to select the best injection method for optimal efficiency.

Future Trends in Injection Tooling for Enhanced Production Efficiency

As the manufacturing landscape continues to evolve, injection tooling techniques are increasingly focused on innovation and efficiency. One of the prominent trends shaping the future of injection tooling is the integration of automation and smart manufacturing technologies. Utilizing robotics and artificial intelligence in the tooling process not only enhances precision but also significantly reduces cycle times. Automated systems can adapt to varying production demands, allowing manufacturers to optimize throughput while maintaining high-quality standards.

Another critical trend is the adoption of advanced materials and processes in injection molding. The development of lightweight and durable composites is paving the way for more efficient tooling designs, which can improve the longevity and performance of molds. Additionally, 3D printing technology is being integrated into the tooling process, enabling rapid prototyping and customization. This approach allows manufacturers to create intricate designs that would be challenging or impossible with traditional methods, all while reducing material waste and costs.

Moreover, sustainability is becoming a central focus in injection tooling practices. Manufacturers are increasingly implementing eco-friendly materials and energy-efficient processes to minimize their environmental impact. This shift not only aligns with global sustainability goals but also appeals to a market that is progressively prioritizing environmentally responsible products. As these trends shape the future of injection tooling, the emphasis on efficiency, adaptability, and sustainability will play a crucial role in driving manufacturing success.

Related Posts

-

2025 How to Choose the Right Injection Tooling for Your Manufacturing Needs

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair

-

Understanding the Future of Plastic Components in Sustainable Manufacturing Processes

-

How to Choose the Right Injection Mold Inserts for Your Manufacturing Needs

-

What is Injection Molded Parts and How They are Made

-

What is Plastic Injection Mold? A Comprehensive Guide for Beginners