Top Surface Finishing Techniques for Enhanced Product Quality?

Surface finishing plays a crucial role in product quality. It enhances aesthetics and improves durability. Various techniques exist, each with distinct advantages. For instance, polishing provides a smooth and shiny surface. This method is often used in metal products to prevent corrosion.

However, choosing the right surface finishing technique is a complex task. Factors like material properties and intended use are critical. Some methods may not achieve the desired results or can be costly. Inadequate surface finishing can lead to poor performance and shortened product lifespan.

Understanding these techniques is essential for manufacturers. Balancing cost, time, and quality is challenging. Surface finishing is both an art and a science. Its importance cannot be overstated in modern manufacturing. Careful consideration and planning are needed to maximize benefits. Ultimately, the right choice can significantly enhance product quality and customer satisfaction.

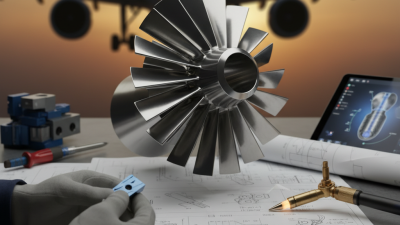

Types of Surface Finishing Techniques and Their Applications

When it comes to enhancing product quality, surface finishing techniques play a vital role. These techniques improve appearance and durability. Common methods include polishing, anodizing, and powder coating. Each has unique applications and benefits.

Polishing is often used to achieve a smooth, shiny surface. It's ideal for products that require a reflective finish, like metal parts. Anodizing, a process primarily for aluminum, enhances corrosion resistance. It also allows for attractive color options. Powder coating provides a durable, protective layer. It’s applicable for various materials, including metals and plastics.

Tips: Always test your selected finishing technique on a small sample first. This helps identify any unexpected issues. Be mindful of the environmental impact. Some finishes produce harmful waste. Reflect on the long-term maintenance needs of finished products. Each method has its pros and cons. Your choice should align with quality goals and environmental responsibilities.

Key Benefits of Surface Finishing for Product Quality Enhancement

Surface finishing techniques play a crucial role in enhancing product quality. They improve not only the appearance but also the durability of products. Smooth surfaces can prevent wear and tear, making items last longer. Finishing techniques like polishing and anodizing offer a sleek look while protecting against corrosion. A well-finished product can attract customers and increase perceived value.

However, the benefits of surface finishing go beyond aesthetics. Enhanced surface quality can improve functionality. For example, coatings can reduce friction and wear, contributing to better performance. Yet, not all finishing methods are eco-friendly. Some require chemicals that may harm the environment. It’s vital to choose processes that balance quality with sustainability.

There's room for improvement in this area. Industries should consider choosing greener options. This requires careful evaluation of current practices and processes. Engaging with new finishing technologies could yield significant advancements. Quality enhancement should not come at the cost of environmental responsibility. The journey towards better surface finishing is ongoing and demands attention.

Step-by-Step Process of Common Surface Finishing Methods

Surface finishing is crucial for product quality. Different methods yield varying results. Here, we outline common techniques and their step-by-step processes.

One popular method is polishing. This begins with selecting the right abrasive. Start with a coarse grit and gradually move to finer ones. Use consistent pressure, but don’t rush. Each pass should reveal a better finish. Sometimes, surfaces can remain uneven or have swirl marks. This is a part of the learning curve.

Another technique is anodizing. This is often used for aluminum. The process involves cleaning the surface thoroughly. Next, submerge the item in an acid bath. A direct electrical current creates an oxide layer. The layer protects and enhances appearance. However, improper timing can lead to varying thickness. This inconsistency may require rework. Understanding these details is key to achieving the desired result.

Top Surface Finishing Techniques for Enhanced Product Quality

| Finishing Technique | Description | Applications | Benefits |

|---|---|---|---|

| Polishing | A process that results in a smooth, shiny surface through abrasion. | Metal parts, jewelry, automotive components. | Enhances aesthetic appeal and reduces friction. |

| Anodizing | Electrolytic process to increase thickness of oxide layer on the surface of metal parts. | Aluminum products, architectural elements. | Improves corrosion resistance, increases surface hardness. |

| Galvanizing | The application of a protective zinc coating to steel or iron. | Construction materials, automotive parts. | Prevents rusting and extends lifespan. |

| Electropolishing | An electrochemical process that removes material from the surface of metallic workpieces. | Food, pharmaceutical, and biotech industries. | Enhances cleanliness and corrosion resistance. |

| Sandblasting | Process of propelling abrasive material using high-velocity air. | Cleaning surfaces and preparing for coatings. | Removes contaminants, creates a textured surface for better adherence. |

Factors Influencing the Choice of Surface Finishing Techniques

Choosing the right surface finishing technique is critical for product quality. Several factors heavily influence this decision. The material type plays a significant role. For metals, techniques like anodizing or plating may enhance durability. Plastic materials might benefit from polishing or coating to improve aesthetics and reduce wear.

Cost considerations also affect choices. Some finishing techniques can be expensive to implement. Budget constraints may push manufacturers toward simpler methods. However, choosing cheaper options may lead to trade-offs in quality. The desired end-use of the product should not be overlooked. A product meant for high-wear environments needs durable finishes to withstand daily use.

Environmental impact is another crucial factor. Specific techniques may produce harmful waste. Manufacturers might face pressure to minimize their carbon footprint. Furthermore, production timelines can impact decisions. Rapidly changing market demands could lead to hasty choices. Often, this results in insufficient testing or later adjustments, raising questions about the effectiveness of the chosen method.

Future Trends in Surface Finishing Technologies and Innovations

The landscape of surface finishing technologies is evolving. Industrial reports show a 20% annual growth rate in this sector, driven by advancements. Companies are focusing on sustainable practices while enhancing product quality.

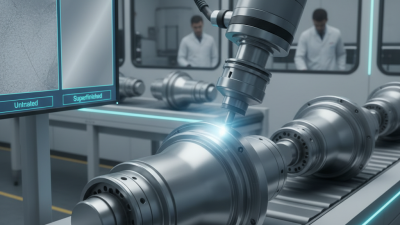

Automation and robotics are pushing boundaries. They improve consistency and reduce human error. However, implementing these systems can be costly. Small to medium enterprises might struggle with the initial investment. Yet, the long-term benefits often outweigh the expenses.

New surface treatments, such as nanotechnology and bio-inspired coatings, are emerging. These innovations can enhance durability and performance. Still, there's a learning curve. Adapting to these technologies requires time and training. Research suggests that 40% of manufacturers feel unprepared for these shifts. This gap highlights the need for ongoing education and adaptation in the industry.

Top Surface Finishing Techniques for Enhanced Product Quality

This chart displays the percentage utilization of various surface finishing techniques in the manufacturing industry, showcasing future trends in surface finishing technologies and innovations.

Related Posts

-

Why is Surface Finishing Process Essential for Product Quality?

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

10 Essential Tips for Using Titanium Alloys in Your Projects?

-

What is Micro Machining? A Comprehensive Guide to Its Techniques and Applications

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

Why Super Finishing Is Essential for Achieving a Surface Roughness of Up to Ra 0.1µm