Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

In today’s rapidly evolving technological landscape, the transformative potential of cutting-edge industrial applications is becoming increasingly evident. These innovative solutions are not merely incremental improvements; they represent a fundamental shift in how industries operate, enhancing efficiency, productivity, and sustainability. By leveraging advanced technologies such as artificial intelligence, the Internet of Things, and automation, businesses can optimize processes and drive significant value creation. This article explores the various types of industrial applications that are reshaping sectors from manufacturing to logistics, showcasing real-world examples and emerging trends. As companies navigate the complexities of digital transformation, understanding the power of these applications will be crucial for maintaining competitive advantage and unlocking new opportunities for growth. Ultimately, the journey of embracing these advancements is not just about technology adoption but also about fostering a culture of innovation that empowers industries to thrive in an increasingly interconnected world.

Exploring the Latest Technologies Revolutionizing Industrial Applications

The landscape of industrial applications is undergoing a remarkable transformation fueled by cutting-edge technologies. Innovations in artificial intelligence, the Internet of Things (IoT), and advanced robotics are redefining how industries operate. AI algorithms analyze vast data sets, enabling companies to optimize operations, predict maintenance needs, and enhance decision-making processes. Meanwhile, IoT devices collect real-time data from machines and systems, allowing for seamless communication and automation. This connectivity not only improves efficiency but also empowers businesses to make informed choices that lead to substantial cost savings.

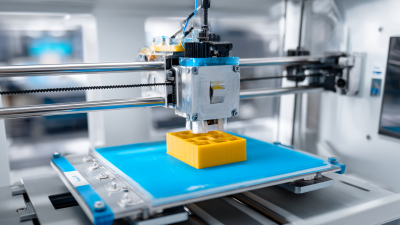

In addition to AI and IoT, additive manufacturing and advanced materials are revolutionizing production capabilities. 3D printing technology enables industries to create prototypes and end products with unprecedented speed and precision, reducing waste and enhancing customization. Moreover, the integration of sustainable materials and practices is becoming increasingly critical, as companies strive to minimize their environmental footprint while maximizing productivity. These technologies collectively create a dynamic environment where industries can innovate, respond to market demands swiftly, and sustain competitive advantages in an ever-evolving marketplace.

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

The chart below illustrates the distribution of recent advancements in various industrial applications and their adoption rates over the past year. The data highlights the rising influence of automation, AI integration, and IoT in transforming industry sectors.

Implementing Smart Automation for Enhanced Operational Efficiency

In today's rapidly evolving industrial landscape, the integration of smart automation has become a pivotal strategy for enhancing operational efficiency. According to a report by McKinsey, companies that implement advanced automated technologies can see productivity improvements of up to 30%. By harnessing technologies such as the Internet of Things (IoT), artificial intelligence (AI), and machine learning, industries can optimize their processes, leading to faster decision-making and reduced downtime.

A recent study from the International Federation of Robotics highlights that the global industrial robot installations are expected to reach 3 million units by 2025. This surge in automation adoption not only streamlines production but also enhances precision, significantly minimizing human error. Furthermore, the World Economic Forum projects that by 2025, automation will save companies an estimated $2.7 trillion annually. As industries continue to embrace smart automation, they will not only gain a competitive edge but also pave the way for innovative solutions that redefine operational standards.

Harnessing Data Analytics to Drive Strategic Decision-Making

In the rapidly evolving landscape of industrial applications, leveraging data analytics has emerged as a cornerstone for driving strategic decision-making. The Decision Intelligence market is poised for substantial growth, with significant applications in decision support, decision augmentation, and analytics as a service. Organizations are increasingly recognizing the value of integrating advanced analytical tools to enhance their operational efficiency and competitive edge. This trend is set to redefine how industries approach problem-solving and resource management.

As companies navigate the complexities of the modern market, analytics as a service offers a scalable solution tailored to their unique needs. By utilizing predictive and prescriptive analytics, businesses can gain deeper insights into market trends, customer behaviors, and operational challenges. The influence of these technologies is amplified by the impacts of recent global events, which have accelerated the demand for agile and data-driven decision-making frameworks. With leading players in the industry continuously innovating, the market is likely to witness transformative changes that will shape the future of decision intelligence and analytics in various sectors.

Transforming Industries: Unleashing the Power of Cutting-Edge Industrial Applications

| Industry | Application | Data Analytics Strategy | Impact on Decision-Making |

|---|---|---|---|

| Manufacturing | Predictive Maintenance | Machine Learning Algorithms | Reduced Downtime |

| Healthcare | Remote Patient Monitoring | Real-Time Data Processing | Enhanced Patient Care |

| Logistics | Supply Chain Optimization | Data Visualization Tools | Increased Operational Efficiency |

| Energy | Energy Management Systems | Predictive Analytics | Cost Savings and Sustainability |

| Retail | Customer Behavior Analysis | Data Mining Techniques | Personalized Marketing Strategies |

Integrating Sustainability Practices into Modern Industrial Solutions

The integration of sustainability practices into modern industrial solutions is no longer optional; it has become a critical component of operational strategy across various sectors. According to a report by McKinsey, 70% of industrial companies are prioritizing sustainability initiatives, driven by both regulatory pressures and consumer demand for greener products. Leading organizations are now embedding sustainability into their operations, from supply chain management to product lifecycle assessments, transforming traditional practices into eco-friendly solutions.

Furthermore, research from the World Economic Forum indicates that sustainable practices can lead to an average cost reduction of 20% in energy consumption and raw materials within manufacturing processes. Innovations such as circular economy models and green energy technology are paving the way for industries to reduce carbon footprints while enhancing operational efficiencies. By leveraging these cutting-edge applications, companies are not only addressing environmental concerns but are also positioning themselves competitively in a market that increasingly favors sustainable practices.

Leveraging IoT for Real-Time Monitoring and Predictive Maintenance

The integration of the Internet of Things (IoT) into industrial applications is revolutionizing real-time monitoring and predictive maintenance. According to recent market reports, the predictive maintenance market is projected to grow significantly, with an estimated compound annual growth rate (CAGR) of over 13% from 2024 to 2032. This growth is fueled by the increasing adoption of Industry 4.0 technologies, which are driving demand for virtual and soft PLCs in manufacturing environments. The total market value for virtual PLCs and soft PLCs was around $8.65 billion in 2023, highlighting the critical shift towards more intelligent systems.

Furthermore, the AIoT market, which combines IoT and artificial intelligence, is expected to soar from $27.92 billion in 2022 to approximately $35.65 billion by 2030, indicating a hefty CAGR of 32.4%. This indicates the robust potential of AI-driven solutions in enhancing predictive maintenance strategies across various industries, enabling companies to reduce downtime and improve operational efficiency. As the condition-based maintenance systems market continues to evolve, characterized by innovations in IoT and AI technologies, industries are strategically leveraging these tools to optimize their maintenance workflows and drive productivity.

Related Posts

-

The Future of Micro Machining Technologies Driving Precision Engineering Innovations

-

Ejector Pins Innovations and Opportunities at the 138th China Import and Export Fair in 2025

-

Exploring Additive Manufacturing Innovations at the 2025 Canton Fair in China

-

The Evolution of Stamping Dies in Metal Forming Industry Trends and Innovations

-

Understanding the Process and Advantages of Plastic Injection Molded Parts in Modern Manufacturing

-

Exploring Innovations in Plastic Injection Molds at the 2025 China Import and Export Fair