Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

As the global manufacturing landscape continues to evolve, the plastic mold industry is poised for significant growth, reflecting the ongoing innovation and demand for high-quality, efficient solutions. The plastic molding market is expected to reach USD 300 billion by 2025, driven by advancements in technology and shifting consumer preferences. The 138th Canton Fair in 2025 will serve as a vital platform for industry stakeholders to explore the latest trends and innovations in plastic mold production. With the rise of sustainable practices and smart manufacturing, this event will showcase cutting-edge techniques and materials that aim to enhance productivity while reducing environmental impact. By attending, participants will gain critical insights into the future of plastic mold manufacturing, highlighting its pivotal role in unlocking the full potential of various industries, from automotive to consumer goods.

Exploring Transformative Trends in Plastic Mold Technology at the 138th Canton Fair

The 138th Canton Fair in 2025 promises to be a focal point for exploring transformative trends in plastic mold technology. As the global plastic mold market is projected to reach USD 29.5 billion by 2026, the need for innovative solutions is increasingly critical. Key advancements include the integration of AI and IoT capabilities, enabling real-time monitoring and predictive maintenance, which are essential for enhancing efficiency and reducing downtime in production processes.

One significant trend observed in recent industry reports is the shift towards sustainable practices. According to a study by Mordor Intelligence, about 55% of manufacturers now prioritize eco-friendly materials and energy-efficient processes when designing molds. This shift not only meets regulatory demands but also appeals to environmentally conscious consumers and businesses.

**Tips:** To gain a competitive edge, industry professionals should invest in training for their teams on the latest mold design software and automation techniques. Additionally, attending workshops at the Canton Fair focused on sustainability can provide insights for integrating green practices into existing operations. Embracing these transformative trends will ensure companies remain at the forefront of innovation in the ever-evolving plastic mold industry.

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025 - Exploring Transformative Trends in Plastic Mold Technology

| Aspect | Details |

|---|---|

| Event Date | April 15-19, 2025 |

| Location | Canton Fair Complex, Guangzhou, China |

| Focus Areas | Sustainability, Innovation, Automation |

| Exhibitor Categories | Mold Manufacturers, Material Suppliers, Machinery Providers |

| Key Technologies Showcased | 3D Printing, Biodegradable Plastics, Smart Mold Systems |

| Expected Attendees | Over 200,000 industry professionals |

| Workshops and Seminars | Sessions on Mold Design, Materials Science, Automation Trends |

| Networking Opportunities | Meetings with R&D teams, Supply Chain Partners, and Industry Leaders |

Showcasing Innovative Applications of Plastic Molds Across Diverse Industries

At the 138th Canton Fair in 2025, the spotlight will be on the innovative applications of plastic molds, reflecting the significant growth potential across various industries. The global automotive molds market, valued at approximately $41.32 billion in 2024, is projected to reach $60.88 billion by 2033, showcasing a compound annual growth rate (CAGR) of around 4.4%. This growth is driven by advancements in mold technology, which are continuously enhancing production efficiency and product quality in sectors such as automotive, packaging, and consumer goods.

Moreover, the rising trend of lightweight packaging is pushing manufacturers to innovate further, particularly in the development of R-PET materials and recycling processes. Many companies are focusing on reducing the weight of products, which not only addresses sustainability concerns but also meets the market's demand for eco-friendly solutions. With the integration of intelligent molding technologies, new devices are being developed that significantly enhance production lines, allowing for the creation of high-quality products while minimizing waste. The Canton Fair will serve as a vital platform for showcasing these advancements and connecting industry leaders to foster collaboration and innovation.

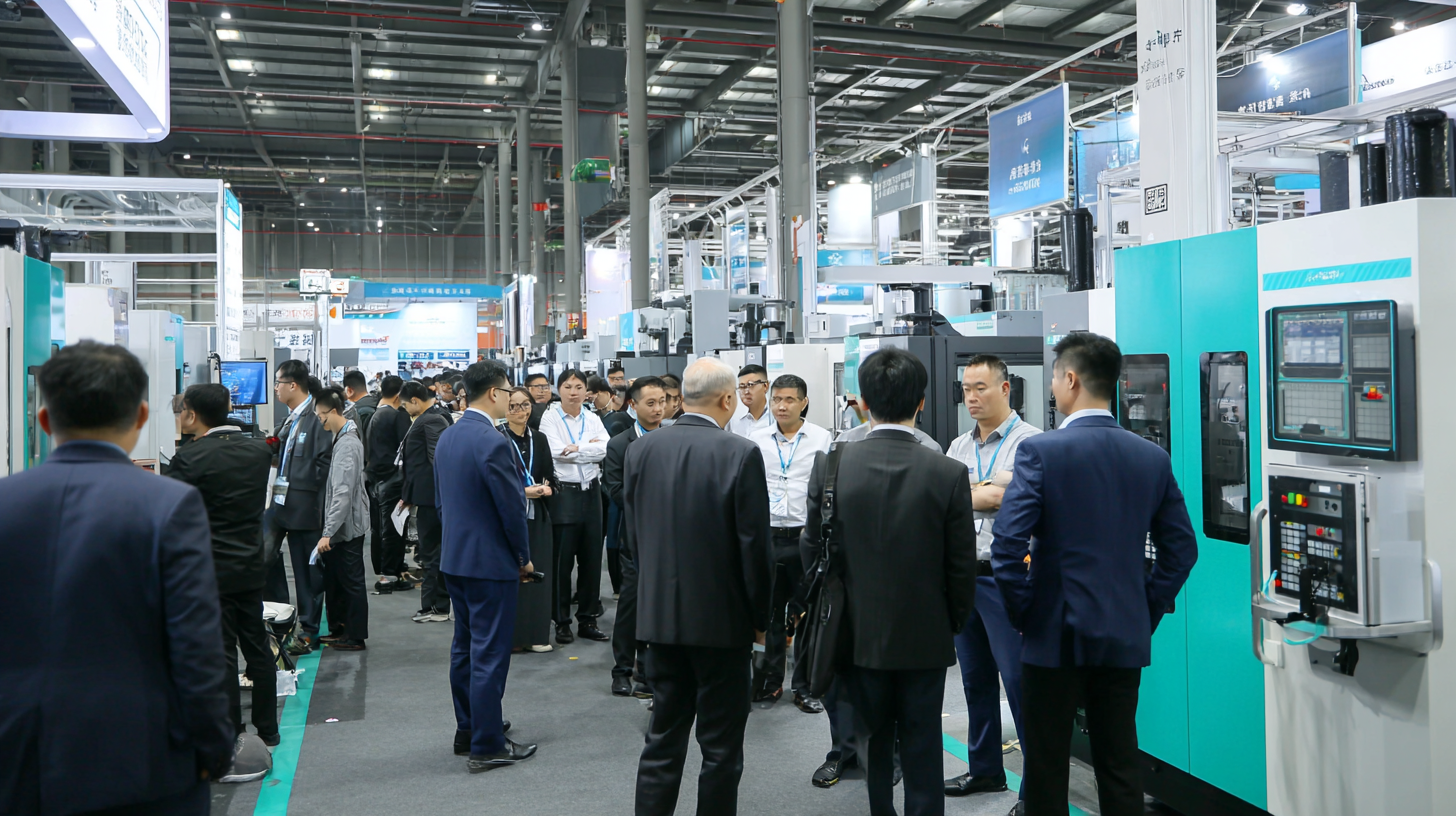

Networking Opportunities: Connecting with Industry Leaders and Experts at the Fair

The 138th Canton Fair in 2025 is not just a showcase for plastic mold innovation but also a valuable networking opportunity for industry leaders and experts. With over 25,000 exhibitors expected, this fair offers an unparalleled chance to connect with key stakeholders and professionals from various sectors. Networking at events like these can open doors to collaboration, investment opportunities, and the sharing of best practices that can significantly propel business growth.

Tips: To make the most of your networking experience at the fair, consider preparing a concise elevator pitch about your work and interests. Engage actively in panel discussions or workshops, as these are prime settings for meeting industry peers and thought leaders. Additionally, don’t hesitate to utilize social media platforms to arrange meetings in advance, establishing connections that could lead to fruitful partnerships.

According to recent market studies, the global injection mold market is poised to reach USD 10 billion by 2026, driven by the rising demand in the automotive and consumer goods sectors. This growth underscores the importance of innovation and collaboration, which will be pivotal themes at the Canton Fair. Leveraging such events not only enhances visibility but also fosters relationships that can lead to the development of cutting-edge solutions within the industry.

Sustainability and Eco-Friendly Practices in Plastic Mold Manufacturing

The spotlight on sustainability and eco-friendly practices in plastic mold manufacturing is more relevant than ever, especially as the plastic injection molding market is projected to grow from USD 10.50 billion in 2025 to USD 13.70 billion by 2033. This growth indicates a robust demand for innovative solutions that minimize environmental impact while meeting production needs. A key focus for manufacturers is the exploration of sustainable materials, such as bioplastics derived from Azolla, which show promise in reducing plastic waste and fostering a circular economy.

Tips for manufacturers looking to innovate sustainably include investing in new production technologies that prioritize eco-friendly materials and practices. Collaborating with partners to tackle common challenges in injection molding can also enhance efficiency and reduce wastage. Furthermore, evaluating and improving recycling methods aligns with consumer preferences and supports the transition to a more sustainable future.

Another avenue for sustainable practices is the ongoing research into polyhydroxyalkanoates (PHAs), which presents opportunities for biodegradable plastics within a circular economy framework. By embracing these advances, the industry can drive meaningful change towards a greener, more sustainable model in plastic mold manufacturing.

Future-Proofing Your Business: Adapting to Market Demands with Mold Innovations

As the market evolves, businesses must constantly adapt to stay competitive. The 138th Canton Fair 2025 is set to showcase innovative plastic mold technologies that promise to meet these changing demands. By integrating advanced mold designs and materials, companies can enhance their production efficiency, reduce waste, and ultimately provide higher-quality products to consumers. These innovations are pivotal in addressing the pressing need for sustainability and cost-effectiveness in manufacturing.

Moreover, the landscape of consumer preferences is shifting more rapidly than ever before. Manufacturers need to be responsive and agile, and adopting cutting-edge mold innovations can significantly future-proof their operations. Customizable molds allow for shorter lead times and greater flexibility in production, enabling businesses to respond quickly to market trends and customer feedback. This adaptability not only boosts productivity but also fosters a culture of continuous improvement, ensuring that companies remain relevant in a dynamic economic environment.