Why Choose Bevel Gears for Your Mechanical Applications?

In the realm of mechanical engineering, bevel gears play a pivotal role in ensuring efficient power transmission and direction change in machinery. As an industry expert, Dr. John Smith, a renowned mechanical engineer, emphasized, "Bevel gears are essential for applications requiring angular motion transfer, allowing for smooth and reliable operation." This highlights the significance of incorporating bevel gears into various applications, from automotive to aerospace, where durability and precision are paramount.

The unique design of bevel gears allows them to transmit torque between axes that intersect, effectively managing the complexities of modern machinery. Their ability to maintain efficiency while minimizing backlash makes them a preferred choice among engineers seeking to enhance performance and reliability. In a world that continually demands innovation and improvement, the utilization of bevel gears stands as a testament to the advances in mechanical design.

As industries evolve, understanding the advantages of bevel gears becomes increasingly vital. Their versatility, combined with a robust ability to handle varying loads and speeds, makes them indispensable in the development of cutting-edge technologies. Thus, exploring the many benefits of bevel gears is crucial for professionals aiming to optimize their mechanical applications and achieve superior operational results.

Understanding Bevel Gears and Their Functionality

Bevel gears are essential components in mechanical systems, designed to transmit power between shafts that are oriented at an angle, commonly at 90 degrees. Their unique conical shape allows for efficient transfer of torque, enabling changes in the direction of motion. This functionality is particularly important in applications where space constraints demand compactness, such as in automotive and aerospace industries. By ensuring a smooth transition of energy, bevel gears help minimize vibrations and wear, ultimately enhancing the performance and longevity of machinery.

Understanding the various types of bevel gears—spiral, straight, and hypoid—can further highlight their functionality. Spiral bevel gears, for instance, feature tooth designs that allow for smoother engagement and higher load capacity, making them suitable for high-speed applications. Straight bevel gears, with their simple geometry, are often employed in lower-speed scenarios where efficiency and straightforward manufacturing processes are prioritized. Meanwhile, hypoid gears are characterized by their unique tooth design that allows for offset shafts, offering advantages in terms of quiet operation and load sharing. Each type serves a specific purpose, allowing engineers to select the appropriate gear to match the mechanical requirements of various applications.

Advantages of Using Bevel Gears in Mechanical Systems

Bevel gears are an essential component in many mechanical systems due to their unique ability to transmit power between shafts that are oriented at right angles to each other. One of the primary advantages of using bevel gears is their efficiency in converting rotational motion. This orientation allows for smoother operation, facilitating the seamless transfer of energy while minimizing losses due to friction. Consequently, they are widely employed in applications requiring high performance and reliability.

Another significant benefit of bevel gears is their compact design. This space-saving feature makes them ideal for applications where installation area is limited, such as in automotive and aerospace systems. Additionally, bevel gears can accommodate various gear ratios, providing versatility in design and allowing engineers to achieve desired output speeds and torques with ease. The ability to customize these gears enhances the overall functionality of mechanical systems, making bevel gears an attractive choice for engineers and designers alike.

Applications of Bevel Gears in Various Industries

Bevel gears are crucial components in a variety of mechanical systems across multiple industries due to their unique ability to efficiently transmit power at an angle. According to a recent report by Market Research Future, the global bevel gears market is projected to grow significantly, driven by heightened demand in sectors such as automotive, aerospace, and manufacturing. In the automotive industry, bevel gears play a vital role in differential systems, allowing vehicles to navigate smoothly around curves by managing speed differentials between the left and right wheels. The efficiency of these gears directly impacts fuel consumption, making them a focal point in developing more sustainable vehicle technologies.

In aerospace applications, bevel gears facilitate the intricate mechanisms required for flight control systems. Their lightweight yet durable construction ensures reliability under varying operational conditions, which is paramount given the stringent safety standards in this sector. A report from Grand View Research indicates that the aerospace sector accounts for a considerable portion of the bevel gears market, with a projected CAGR of 4.5% from 2022 to 2030. Moreover, in the manufacturing industry, bevel gears are employed in various machinery, providing flexibility and precision in tasks ranging from conveyor systems to robotics. This versatility not only enhances productivity but also underscores the essential role bevel gears play in the advancement of industrial technology.

Comparing Bevel Gears with Other Gear Types

Bevel gears are a critical component in mechanical applications, particularly when it comes to transferring power between shafts that are not parallel. Compared to other gear types, such as spur or worm gears, bevel gears offer unique advantages due to their ability to function effectively at varying angles, typically between 90 and 180 degrees. According to a report by the Gear Research Institute, bevel gears are estimated to make up approximately 20% of the global gear market, highlighting their significance in various industries, especially in automotive and aerospace sectors where space efficiency is paramount.

When comparing bevel gears to spur gears, one notable advantage lies in the efficiency and reduced noise levels. Bevel gears generally operate with lower vibration and less backlash, making them suitable for high-speed applications. A study published in the Journal of Mechanical Engineering found that bevel gear pairs have a power transmission efficiency of over 90% when properly designed and manufactured. Additionally, the self-locking nature of bevel gears allows them to provide a greater mechanical advantage in applications requiring high torque, something that worm gears cannot always offer without significant efficiency losses.

In terms of design flexibility, bevel gears are often favored for their compactness and versatility in orientation, fitting seamlessly into spaces where other gear types may struggle. This adaptability is especially crucial in precision engineering scenarios. With ongoing advancements in materials and manufacturing processes, the durability and performance metrics of bevel gears continue to improve, solidifying their role as a vital choice in mechanical design over traditional gear types.

Why Choose Bevel Gears for Your Mechanical Applications? - Comparing Bevel Gears with Other Gear Types

| Gear Type | Applications | Advantages | Disadvantages |

|---|---|---|---|

| Bevel Gears | Power transmission at right angles | Compact design, smooth operation, high load capacity | Complex manufacturing, alignment sensitivity |

| Spur Gears | Linear applications, rotary motion | Simple design, easy to manufacture | Noisy operation, limited to parallel axes |

| Helical Gears | High-speed applications, heavy loads | Smooth and quiet operation, higher strength | More complex to manufacture, axial thrust |

| Worm Gears | Low-speed, high-torque applications | High reduction ratios, compact design | Low efficiency, heat generation |

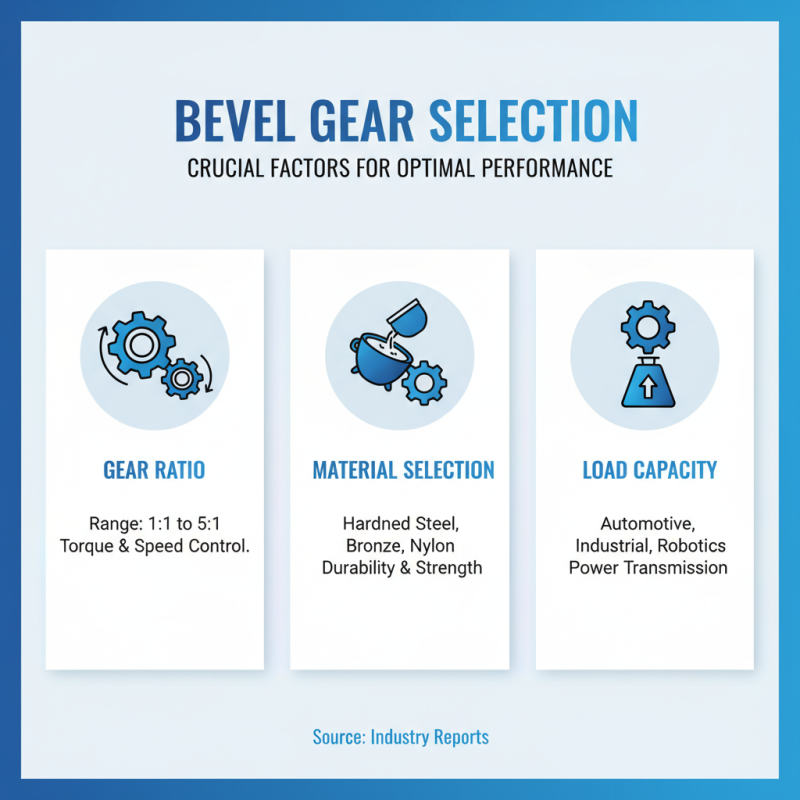

Key Considerations When Choosing Bevel Gears for Your Project

When selecting bevel gears for mechanical applications, there are several crucial factors to consider to ensure optimal performance and longevity. The most significant considerations include the gear ratio, material selection, and load capacity. According to industry reports, bevel gears can achieve gear ratios ranging from 1:1 to 5:1, making them versatile for various applications, from automotive drivetrains to industrial machinery. Understanding the specific gear ratio required for your project will help in choosing the right bevel gear to provide the necessary torque and speed.

Material choice plays a vital role in the durability and performance of bevel gears. Common materials include steel, brass, and plastic, each offering distinct advantages depending on the application. For high-load applications, materials like heat-treated steel are preferred for their strength and resistance to wear. In contrast, lighter applications may benefit from the cost-effectiveness of plastic. A recent analysis highlighted that using high-quality materials can extend the lifespan of bevel gears by up to 30%, reducing the overall maintenance costs for any project.

**Tips:** Always consider the load capacity of your bevel gear system; exceeding the recommended load can lead to premature failure. Additionally, aligning the gears correctly during installation will minimize wear and enhance efficiency. Finally, evaluating the lubrication method, whether oil or grease, can significantly impact the operational performance and lifespan of your bevel gears.

Related Posts

-

How to Choose the Right Bevel Gears for Your Precision Engineering Needs

-

Exploring Innovation: How Plastic Industries are Shaping Sustainable Technology for the Future

-

Understanding the Role of Plastic Injection Molds in Modern Manufacturing Processes

-

Unlocking Industry Potential with Plastic Mold Innovation at the 138th Canton Fair 2025

-

How to Choose the Right Machining Tools for Your Project Success

-

Top Benefits of Micro Machining for Precision Engineering Applications